Chart 3 third visu al ch eck, 6 chart 3 third visual check – Hired-Hand Super-Savers (Forced Air Heaters) XL: Maywick SS-225-XL Rev 6-09A User Manual

Page 16

Part

No.

4801-5801

Rev.

6-09

Page

16

of

23

Super Saver XL Heater Maywick

9.6

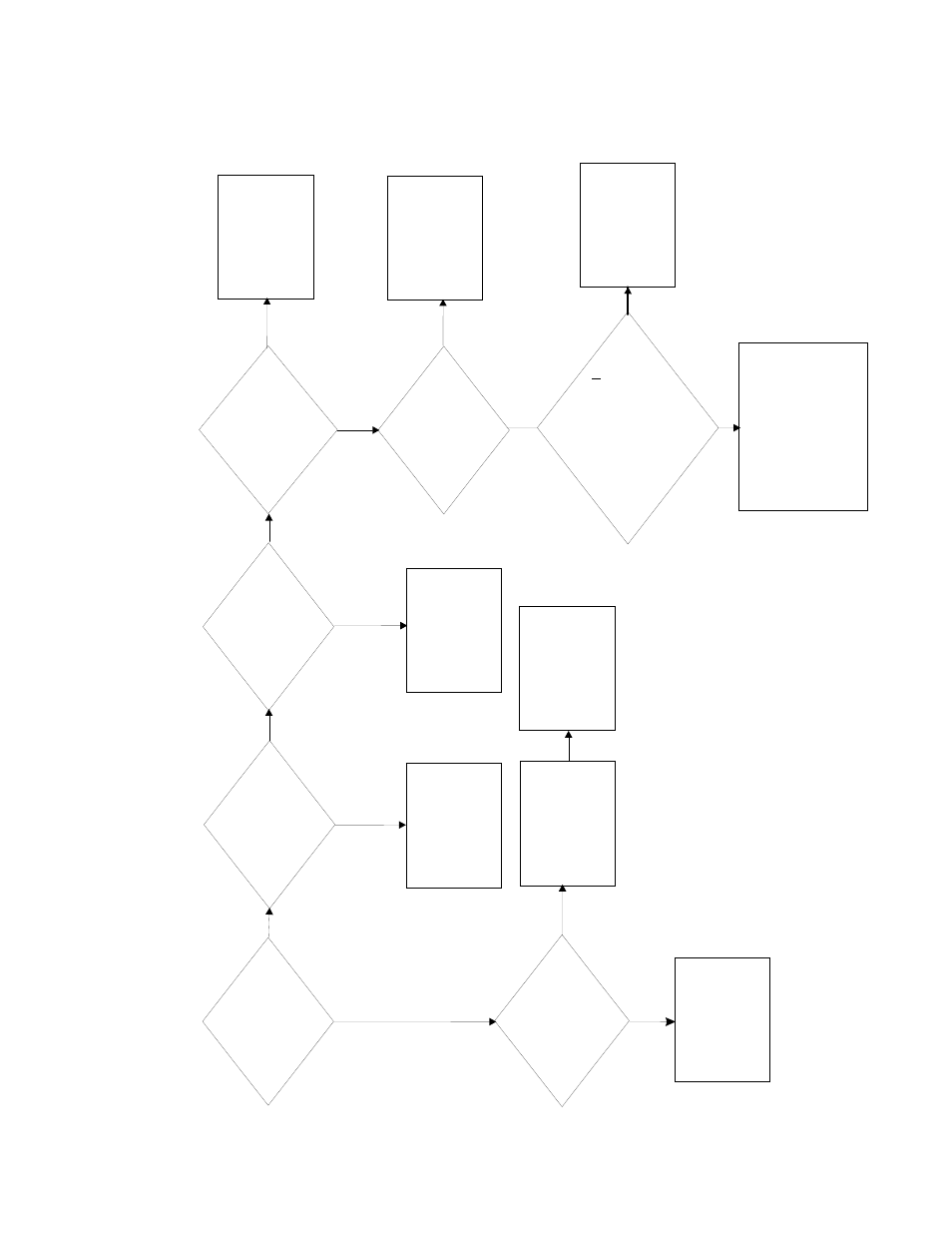

Chart 3 Third Visual Check

Chart 3

Third Visu

al Ch

eck

Does main

burn

er

rema

in l

it

after

lo

ckout

time

?

Does

flam

e

sense probe

have carbon

or

dust build-up

?

De-en

erg

ize

system. Connect

ohm

m

eter

acr

o

ss sensor

and gr

ound.

I

s r

es

istance

less than

50 m

eg ohm

?

Di

sc

on

ne

ct

se

nso

r lead

at

mo

du

le.

Co

n

n

ec

t

oh

mme

ter Acr

o

ss

se

nso

r lead

t

ermin

al

an

d se

ns

or.

Doe

s

co

nti

nu

ity

exis

t?

Replace s

ensor.

Energi

ze

s

y

st

em

and

check

for prop

er

operation.

Rem

ove f

lam

e sensor

.

Clean surface

of

fl

ame

sensor

r

od with the

steel wool or

em

ery

cloth, then reinstal

l.

Replace s

ensor.

Energi

ze

s

y

st

em

and

check

for prop

er

operation.

Is

inpu

t gro

und

wire

d to

b

u

rn

er

g

rou

nd

?

Connect

g

rou

nd

w

ir

ing

.

Do

es ig

n

iter tu

rn

o

ff

with main burner

flame still pres

ent?

Ig

n

iter re

main

s

h

eated

(b

rig

h

t red

)

With main burner

flame present.

Repla

ce

Electronic Contr

o

l

Module.

Replace electronic

co

n

tro

l modu

le.

Is

fl

ame sensor

pr

obe

located pr

oper

ly

in flame?

Proper l

o

cation

would pr

ovide aequate f

lame

cur

re

nt yet not exceed m

axim

u

m

rod temperatu

re.

Micro

m

eter

reads 2

μa or

g

reater

.

N

o

No

No

No

Yes

Yes

Yes

Yes

Yes

Rep

o

sition

flame sen

se

probe to achie

ve

2

μa or

greater

se

nsor current or,

if attainable,

re

place

PSE-

H

HI sens

or

.

HS

I s

y

st

em cy

cl

e

compl

ete

.

NOTE: All vol

tage rea

d

ing

s

+

1

0%

-

15

%

No

No

Yes

No

Yes