0 maintenance & service, 1 troubleshooting, 2 maintenance & service procedures – Condec PIN8010 User Manual

Page 11: Maintenance & service, Caution

Maintenance & Service

5

4.0

Maintenance & Service

This section outlines the mechanical and basic electrical repair procedures for the PIN8000/PIN8010.

4.1

Troubleshooting

Table 4-1. PIN8000/PIN8010 Troubleshooting

Symptom

Problem

Remedy

The customer’s electronic standard

display or the output pressure gauge

slowly decreases over time.

Leak in the system.

Check all compression and pipe fittings

with Snoop

®

, bottle of liquid leak gas

detector (PN 64781).

The electronic standard display or output

pressure gauge fluctuates when the

output pressure or vent valves are

closed.

No pressure or vent control.

Replace the valve seats or O-rings in

valves; check valve needles.

The electronic standard display or output

pressure gauge does not respond when

the vernier knob is turned.

No vernier control.

Re-adjust the isolation valves on the

Orion 3A; replace the vernier piston’s

O-ring.

The unit does not cycle when the pump

control switch is on.

Fuse blown on the pump control board.

No power.

Replace the fuse.

Check that the power is on.

The unit cycles, but does not pressurize.

Debris in check-valve seat in intensifier,

deformity in seat.

No supply pressure.

Remove seats in the intensifier and clean

and/or replace.

Check to see if there is sufficient supply

pressure.

4.2

Maintenance & Service Procedures

The repair procedures cover the major components and sub-assemblies which are critical to the proper

functioning of the calibrators and that need periodic maintenance over the life of the unit.

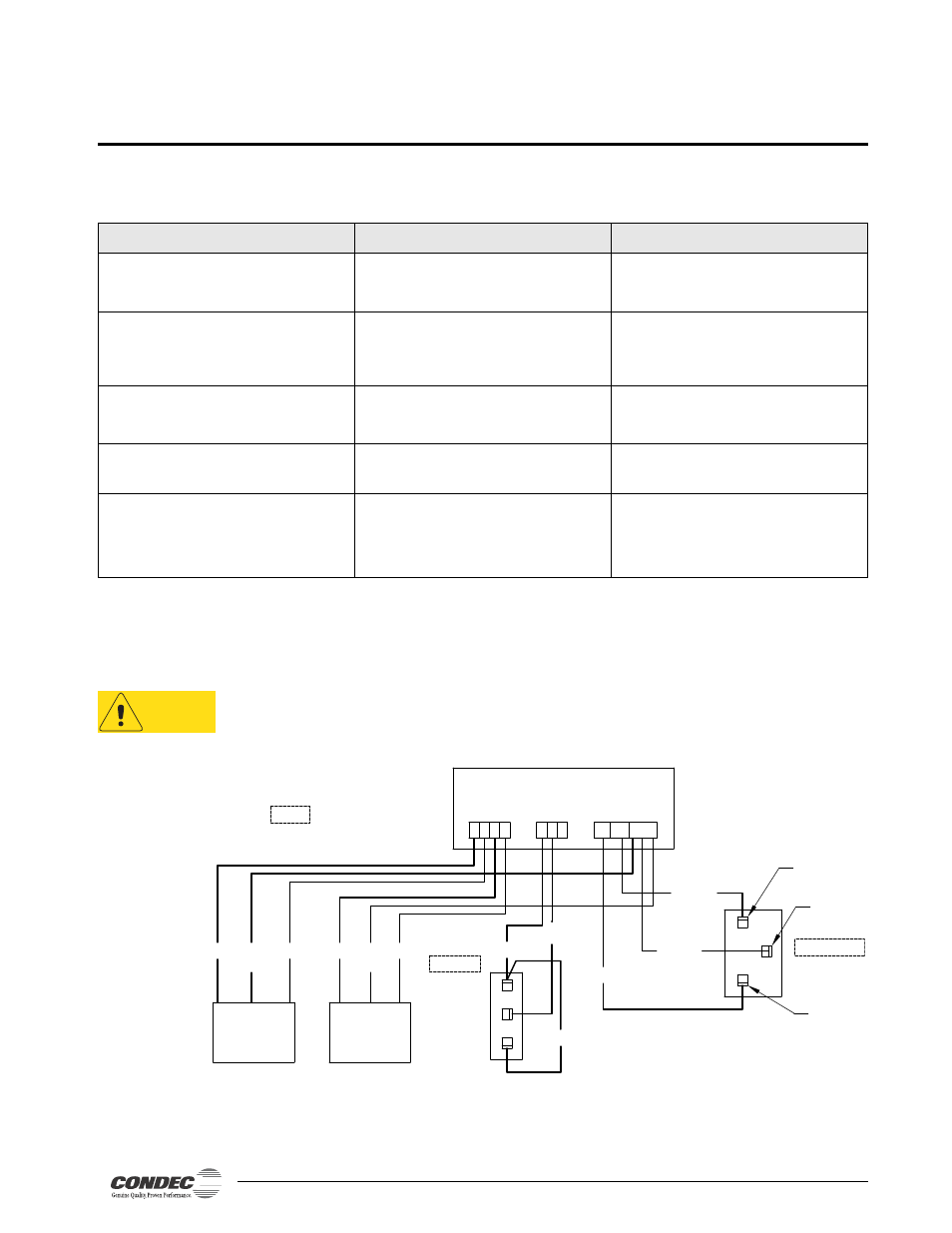

POWER

AC INPUT

LINE (P)

KBK8924-1, (56679)

BLACK

PUMP CONTROL BOARD ASSEMBLY

NOTE: MARKINGS SHOWN WITHIN " " ARE ACTUAL

PART NO.

SOLENOID

RED

56851

VALVE

YEL

GRN/

RED

MARKINGS ON UNIT.

SOLENOID

VALVE

PART NO.

56851

YEL

GRN/

RED

RED

BLACK

BLACK

1 2 3

TB1

GREEN

WHITE

BLACK

4

1 3

2

GND

LO

HI

NEUTRAL

GROUND

TB2

TB3

LINE FILTER

(N)

(E)

(1)

(2)

(3)

(ON)

(OFF)

(MOM)

CAUTION

Only those persons who are formally trained as skilled technicians should attempt to repair these

units. All safety precautions should be observed due to the presence of electrical and high-pressure

components. The unit must always be unplugged from the power source and properly vented.

Figure 4-1. PIN8000/PIN8010 Wiring Diagram