Nexo GEO T User Manual

Page 34

Page 34/67

GEO

T

RIGGING PROCEDURE

To be lifted in “Compression mode – Half Kelping Beam”, the GEO T bumper requires either:

• one motor hoist and a bridle;

• or two motor hoists (easier initial angle setting);

In both cases, ensure that the motors are properly rated.

IMPORTANT

Motor hoists must be rated to support the entire cluster weight.

For arrays of 6 to 18 cabinets, 1 tonne motor hoists are sufficient.

Arrays of 18 cabinets and above should be supported with 2-tons capacity motor hoists.

4.5.1 Front Kelping beam to bumper

• Disconnect Rear Beam from Front Beam by removing connecting axis. Store Rear Beam.

• Link the motor hoists to the Kelping Beam using front and rear upper axis (fixed beam), and

ensure that these axes are properly locked with the “R” clips supplied.

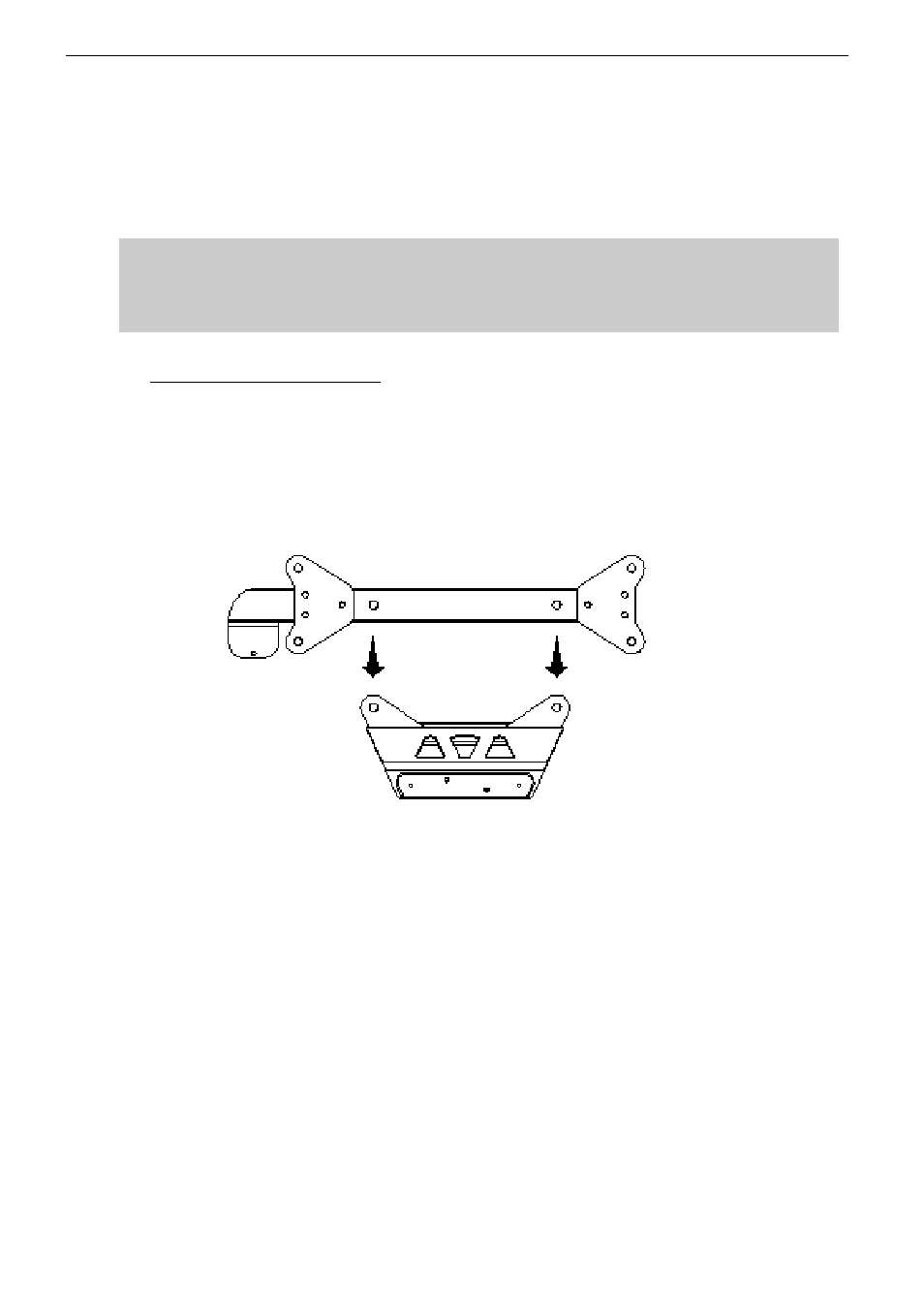

• Lift the Kelping Beam and position the bumper below it.

• Lower the Kelping beam so that the front beam load pin holes are aligned with the bumper load

pin holes (see drawing).

KELPING BEAM TO BUMPER SETUP

• Connect the Kelping Beam to the bumper with the two axes through the corresponding holes

(see drawing above) and ensure that these are properly locked with the “R” clips.

• Attach theChain Lever Hoist LEVA1500 chain hook to the Kelping Beam rear lower axis see

drawing below).

• NB : the Chain Lever Hoist LEVA1500 connects to the bottom GEO T4805, and a small bag is

provided for excess chain.