Nexo GEO T User Manual

Page 32

Page 32/67

GEO

T

RIGGING PROCEDURE

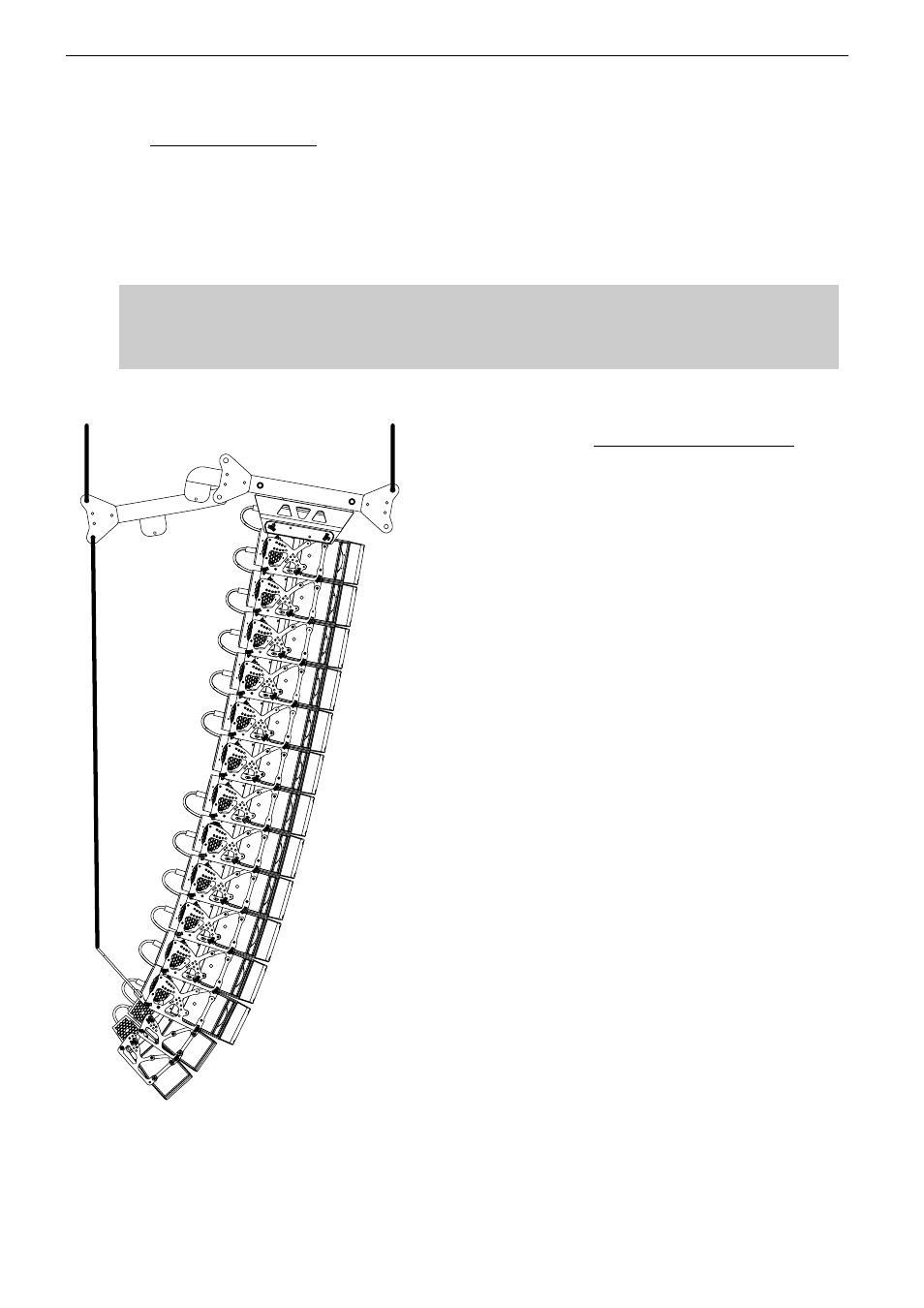

4.4.8 Positioning the cluster

• Adjust the overall height and aiming angle of the array by adjusting the front and rear motor

hoists accordingly. Note that the accuracy of the angle and height of the array are critical and the

appropriate measurement tools are necessary to achieve this (see the appendix for a

recommended list of installation tools).

• Install a secondary safety steel between the Kelping Beam and a suitable point in the supporting

structure.

IMPORTANT

The requirements for secondary safety systems vary with territories. However, the

secondary safety steel MUST have a SWL equivalent to or greater than that of the rigging

system.

4.4.9 De-rigging and loading out

Taking the system down is just a case of doing

the reverse procedure to flying the array.

However, there are some important factors to

consider.

• Lower the array running the

two motor hoists

simultaneously until the

bottom cabinet is just off the

floor.

• Run the rear motor hoist

down until there is no

tension on the GEO T

kelping chain and no

compression on the system.

• Disconnect the GEO T

kelping chain from the GEO

T bottom bumper and

remove the bottom bumper

from the array. (You may

have to remove the T2815’s

first)

• Run the rear motor hoist

back up until the GEO T

kelping beam is level and

the array hangs vertically.

• Link cables must be

disconnected and stowed

away in the recesses in the

rear of each cabinet.

• NB : As the system is

lowered it is good practise to

disconnect as many

loudspeaker cables as can

be reached without climbing

the array. This ensures that

10 GEO T 4805 + 2 GEO T 2815 set in compression mode