Stuart Turner Techflo Turbo 15TNH User Manual

Page 10

- 10 -

Cont ...

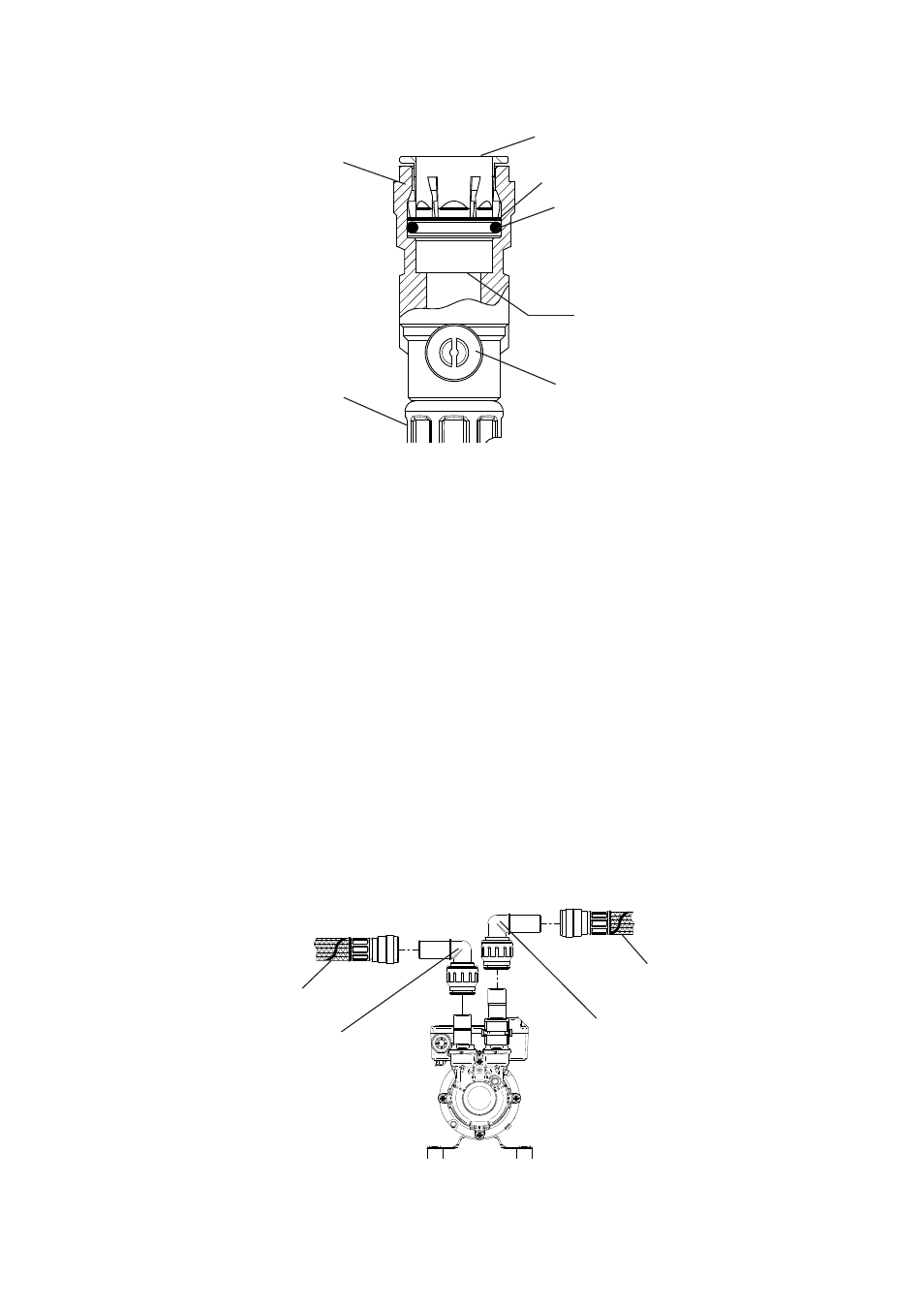

3. Check in the mouth of the fitting that ‘O’-ring, nylon washer and collet are in

position.

4. Push pipe firmly into fitting, until pencil mark is level with the top of the collet

and the pipe stop resistance is felt. Pull on pipe to check it is secure and

correctly

fitted.

5. To break the joint, push pipe firmly into fitting, hold collet down and gently

remove pipe. If the system has been filled with water care should be taken to

isolate pump and towels used to absorb spilled water.

3.13

Typical Low Level Installation:

In certain installations it may be necessary to install a 90° bend on the inlet

or outlet connections of the pump before the flexible hose to accommodate a low

level

installation.

Below is the preferred connection option.

It is essential when using any of the fittings shown below, that a correct water tight

seal is obtained between the pump and the selected fitting and also the flexible

hose and selected fitting. If in doubt contact the fitting manufacturer and confirm

compatibility with the connection to be sealed.

Carefully check connections and pipework for leaks whilst pump running and

stationary before leaving the installation unattended.

If you have any concern either about using push-in fittings or should the

joint leak on final test isolate the water supplies and contact Techflow

Technical Helpline on 01444 258017.

Fig. 9

Body

Collet

Washer

‘O’-Ring

Pipe Stop

Hose

Isolating Valve

Fig. 10

Hose

22 mm stem

elbow

Hose

22 mm stem

elbow