3 installation of sensor with standard options – Yokogawa ISC40 Inductive Conductivity Sensor User Manual

Page 14

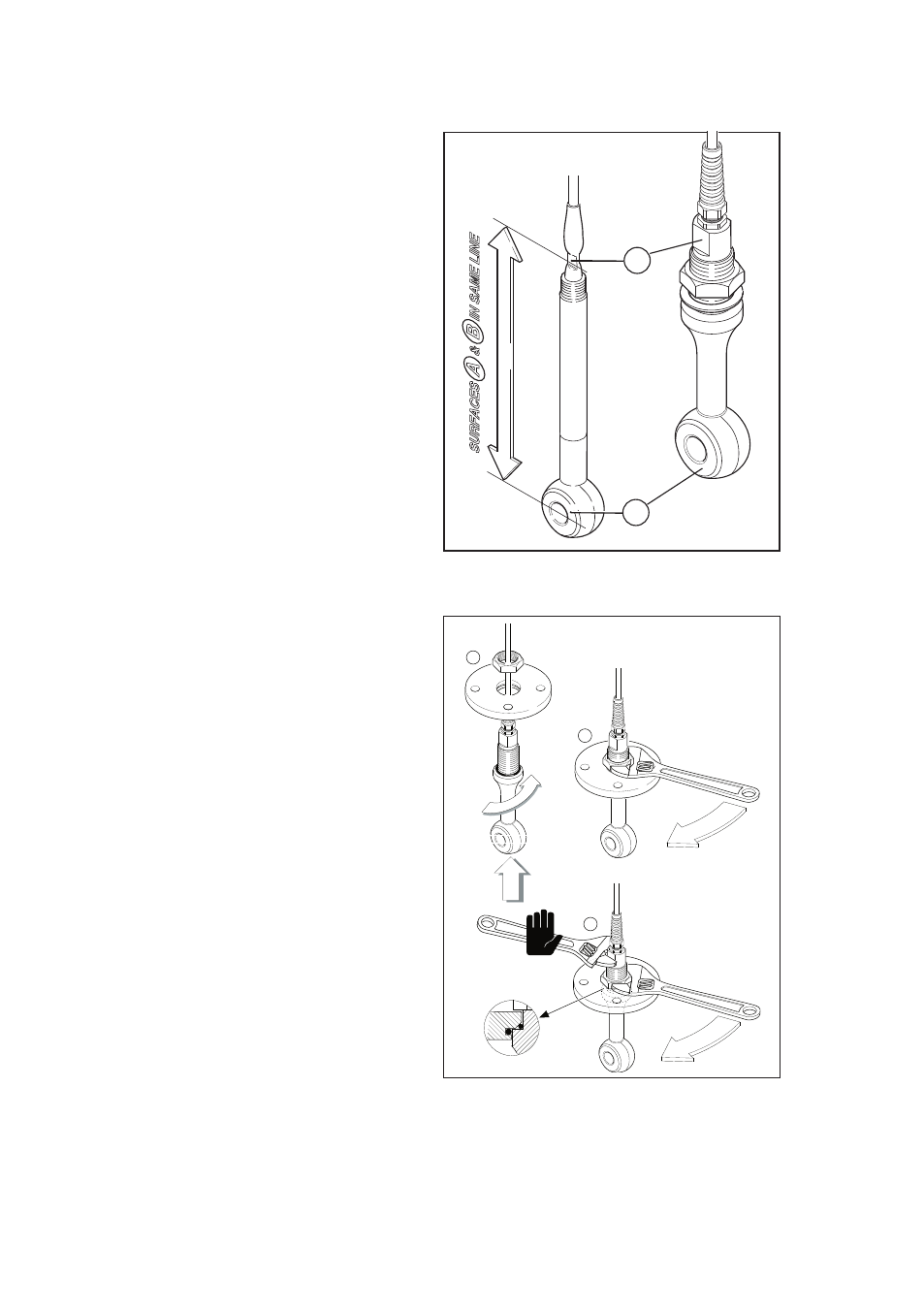

For optimum measurement results,

the ISC40 sensor should be installed

in a location that offers an acceptable

representation of the process composition

and DOES NOT exceed the specifications

of the sensor.

It is important that the process flow is

directed through the hole in the donut

of the sensor. For this reason the flats

on the sensor top part have to be installed

perpendicular on the process flow

(see fig. 4).

The inductive conductivity measurement

technique requires a process fluid

surrounding the donut of the sensor. The

installation factor mentioned on the label

of the sensor cable will assure accurate

conductivity measurement under the

condition that the donut is surrounding by

25 mm (1”) process fluid. If this condition

cannot be met, the measurement loop

(analyser in combination with sensor) has

to be calibrated. Consult the instruction

manuals of the analyser for details.

The mounting of the sensor in the process

adapters is described in section 3.1. The

mounting of the process adapters in the

end-users application requires compatibility

of materials and process connections.

3.1 Typical installation

3.1.1 Installation of ISC40G(S)-GG (TG)

with flange adapters

The ISC40G(S)-GG (TG) sensor is

supplied with a flat Viton sealing gasket

for compatibility with existing installations.

When using the sensor in combination with

the new fittings, which are improved by the

addition of O-ring seals (see figure 6), the

flat Viton gasket should be discarded.

It is important that the access port has a

diameter of at least 50 mm (2”) to allow

insertion of the donut shaped end of the

sensor. For more detailed dimensions of the

sensor see paragraph 4.

A

B

2

1

PUSH & TURN

3

DO NOT WRENCH

TORQUE MAX. 25Nm.

3 INSTALLATION OF SENSOR WITH STANDARD OPTIONS

Fig 4: Aligning of sensor donut (B) and

flats (A)

Fig 5: Mounting Procedure ISC40G(S)-

GG (TG) with flange adapters

Note: When a torque of more than 25 Nm

is applied, the top part of the body

of the PFA sensor will be damaged

(TG model)

14

IM 12D8J2-E-E