Yokogawa EJA110A User Manual

Page 72

IM 01C21B01-01E

10-8

10. GENERAL SPECIFICATIONS

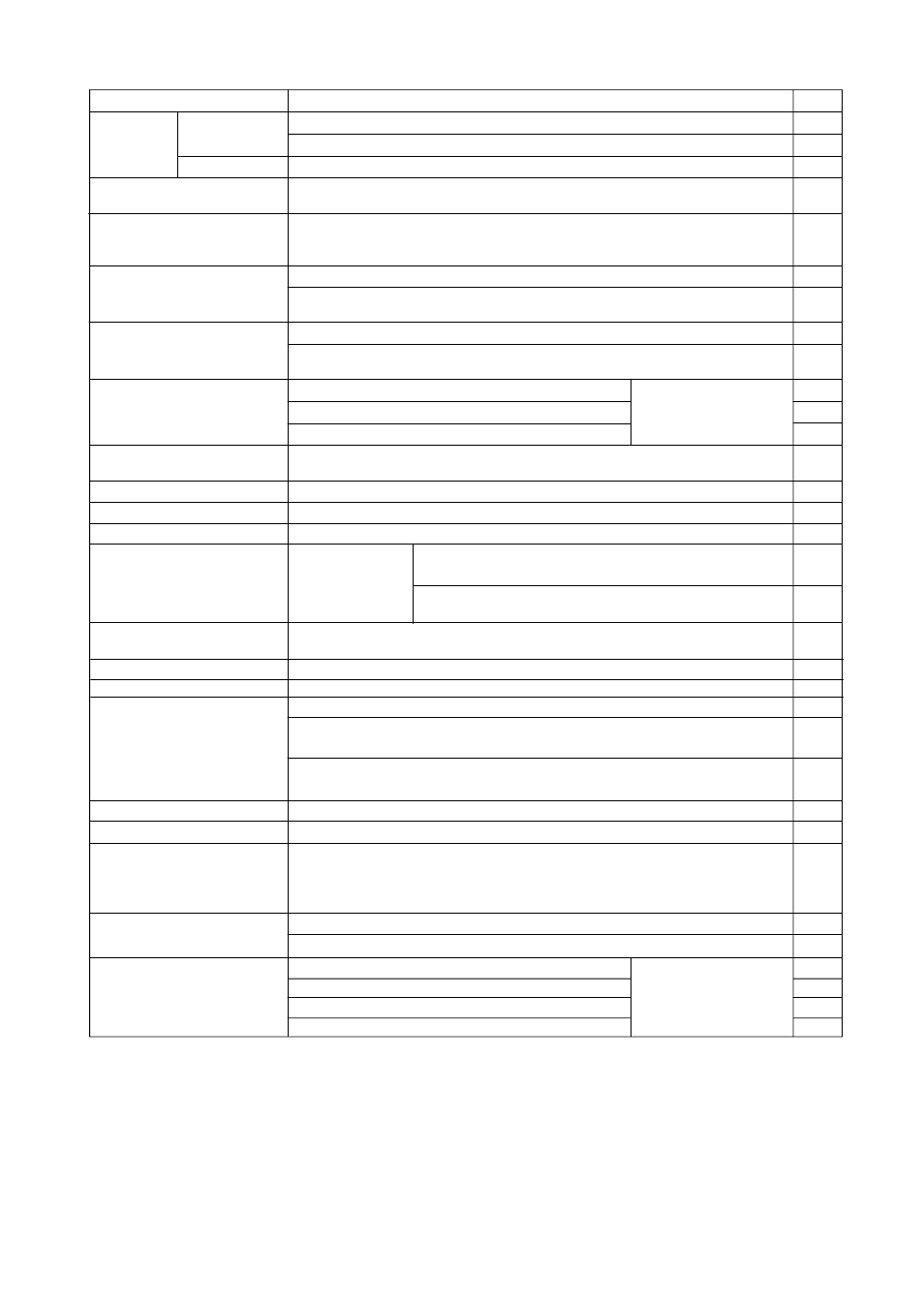

Item

Description

Code

Painting

Color change

Coating change

Lightning protector

Calibration units

Sealing treatment to

SUS630 nuts

Long vent

Failure alarm down-scale

*1

P

ᮀ

PR

X1

A

K1

D1

D3

D4

Y

U

C1

C2

C3

( See Table for Span and

Range Limits.)

Amplifier cover only

Amplifier cover and terminal cover, Munsell 7.5 R4/14

Epoxy resin-baked coating

Transmitter power supply voltag: 10.5 to 32 V DC (10.5 to 30 V DC for intrinsically safe

type, 9 to 32 V DC for F

OUNDATION

Fieldbus and PROFIBUS PA communication type.)

Allowable current: Max. 6000 A (1

ϫ

40

s), Repeating 1000 A (1

ϫ

40

s) 100 times

Degrease cleansing treatment

P calibration ( psi unit )

bar calibration ( bar unit )

M calibration (kgf/cm

2

unit )

Sealant ( liquid silicone rubber ) is coated on surfaces of SUS630 nuts used for cover

flange mounting.

Total vent plug Length: 112 mm (standard, 32 mm), Material: SUS316

Fast response

*4

F1

Update time: 0.125 sec or less, see GS for response time

Output status at CPU failure and hardware error is –5%, 3.2 mA or less.

K2

Degrease cleansing treatment with fluorinated oilfilled capsule.

Operating temperature –20 to 80

°

C

Oil-prohibited use

Mill Certificate

Cover flange

Cover flange, Process connector

Test Pressure: 3.5 MPa{35 kgf/cm

2

}

Test Pressure: 16 MPa{160 kgf/cm

2

}

Test Pressure: 50 kPa{0.5 kgf/cm

2

}

Test Pressure: 32 MPa{320 kgf/cm

2

}

M01

M11

T01

T12

T04

T09

Pressure test/Leak test Certificate

Nitrogen(N

2

) Gas

*3

Retention time: 10 minutes

K5

Degrease cleansing and dehydrating treatment

K6

Degrease cleansing and dehydrating treatment with fluorinated oilfilled capsule.

Operating temperature –20 to 80

°

C

Oil-prohibited use

with dehydrating treatment

Stainless steel amplifier

housing

Amplifier housing material: SCS14A stainless steel

(equivalent to SUS316 cast stainless steel or ASTM CF-8M)

E1

Gold-plate

Body option

Stainless steel tag plate

A1

N1

N2

Gold-plated diaphragm

High Accuracy type

HAC

High Accuracy (Applicable for Model EJA120A)

T1009.EPS

N3

N4

Without drain and vent plugs

N1 and Process connection on both sides of cover flange with blind kidney flanges

on back

N1, N2, and Mill certificate for cover flange, diaphragm, capsule body, and blind

kidney flange

JIS SUS 304 stainless steel tag plate wired onto transmitter

Configuration

Custom software configuration (Applicable for Model EJA110A and EJA130A)

R1

NAMUR NE43 compliant

*1

Output signal limits:

3.8 mA to 20.5 mA

Failure alarm down-scale: output status at CPU failure and

hardware error is –5%, 3.2 mA or less.

Failure alarm up-scale: output status at CPU failure and

hardware error is 110%, 21.6 mA or more.

PE3

European Pressure Equipment

Directive

*2

PED 97/23/EC

(Applicable for Model EJA130A)

CATEGORY: III, Module: H, Type of Equipment: Pressure Accessory - Vessel,

Type of Fluid: Liquid and Gas,

Group of Fluid: 1 and 2

316 SST exterior parts

Exterior parts on the amprifier housing (nameplates, tag plates, zero-adjustment screw,

stopper screw) will become 316 or 316L SST.

HC

*1:

Applicable for Output signal code D and E. The hardware error indicates faulty amplifier or

capsule. When combining with Optional code F1, output status for down-scale is –2.5%,

3.6 mA DC or less.

*2:

Lower limit of process temperature is –30

Њ

C when Bolts and nuts material code A is selected.

*3:

Applicable for EJA110A and EJA120A. For EJA130A, the test fluid is water or Nitrogen (N

2

)

gas.

*4:

Applicable for Output signal code D and E. Write protection switch is attached for Output code E.