Installing impulse piping, 1 impulse piping installation precautions, 1 connecting impulse piping to the transmitter – Yokogawa EJA110A User Manual

Page 26: Installing impulse piping -1, Impulse piping installation precautions -1, Connecting impulse piping to the transmitter -1

IM 01C21B01-01E

5-1

5. INSTALLING IMPULSE PIPING

5.

INSTALLING IMPULSE PIPING

5.1 Impulse Piping Installation

Precautions

The impulse piping that connects the process outputs to

the transmitter must convey the process pressure

accurately. If, for example, gas collects in a liquid-

filled impulse piping, or the drain of a gas-filled

impulse piping becomes plugged, the impulse piping

will not convey the pressure accurately. Since this will

cause errors in the measurement output, select the

proper piping method for the process fluid (gas, liquid,

or steam). Pay careful attention to the following points

when routing the impulse piping and connecting the

impulse piping to the transmitter.

5.1.1 Connecting Impulse Piping to the

Transmitter

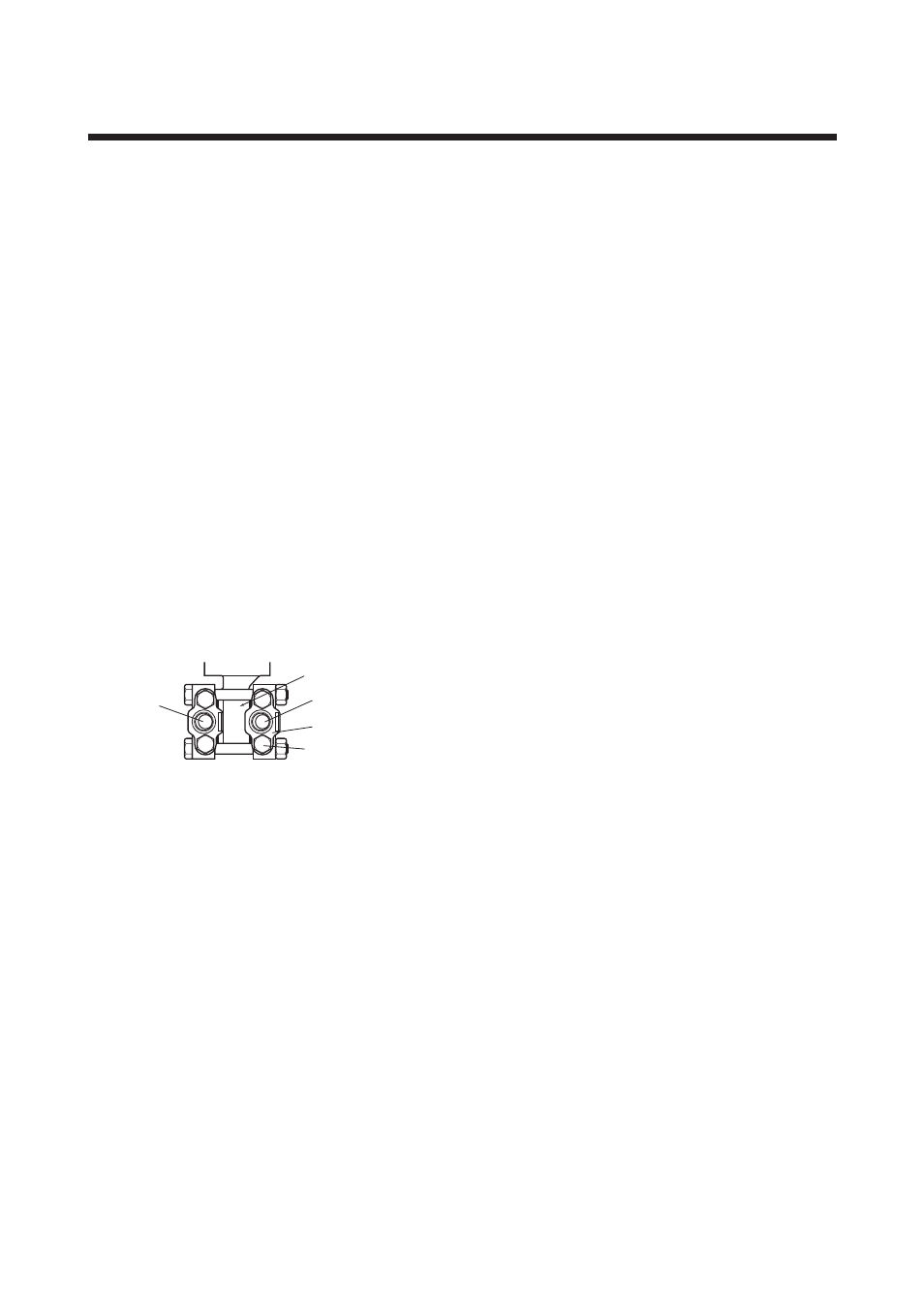

(1) Check the High and Low Pressure Connec-

tions on the Transmitter (Figure 5.1.1a)

Symbols “H” and “L” are shown on a capsule assem-

bly to indicate high and low pressure side. Connect the

impulse piping to the “H” side, and the low impulse

piping to the “L” side.

F0501.EPS

Pressure

connection

“H” and “L” are shown

Process connection

Process connector

Bolt

Figure 5.1.1a “H” and “L” Symbols on a Capsule

Assembly

(2) Changing the Process Connector Piping

Connections (Figure 4.1)

The impulse piping connection distances can be

changed between 51 mm, 54 mm and 57 mm by

changing the orientation of the process connectors.

This is convenient for aligning the impulse piping with

the process connectors when connecting the piping.

(3) Tightening the Process Connector Mount-

ing Bolts

After connecting the impulse piping, tighten the

process connector mounting bolts uniformly.

(4) Connecting the Transmitter and 3-Valve

Manifold

A 3-valve manifold consists of two stop valves to

block process pressure and an equalizing valve to

equalize the pressures on the high and low pressure

sides of the transmitter. Such a manifold makes it

easier to disconnect the transmitter from the impulse

piping, and is convenient when adjusting the transmit-

ter zero point.

There are two types of 3-valve manifold: the pipe-

mounting type and the direct-mounting type; care

should be taken with respect to the following points

when connecting the manifold to the transmitter.

Pipe-Mounting Type 3-Valve Manifold

(Figure 5.1.1b)

1) Screw nipples into the connection ports on the

transmitter side of the 3-valve manifold, and into the

impulse piping connecting ports on the process

connectors. (To maintain proper sealing, wind

sealing tape around the nipple threads.)

2) Mount the 3-valve manifold on the 50 mm (2-inch)

pipe by fastening a U-bolt to its mounting bracket.

Tighten the U-bolt nuts only lightly at this time.

3) Install the pipe assemblies between the 3-valve

manifold and the process connectors and lightly

tighten the ball head lock nuts. (The ball-shaped

ends of the pipes must be handled carefully, since

they will not seal properly if the ball surface is

scratched or otherwise damaged.)

4) Now tighten the nuts and bolts securely in the

following sequence:

Process connector bolts

→

transmitter-end ball head

lock nuts

→

3-valve manifold ball head lock nuts

→

3-valve manifold mounting bracket U-bolt nuts