About profibus pa, 1 outline, 2 internal structure of the eja – Yokogawa EJA115 User Manual

Page 15: 3 logical structure of each block, 4 wiring system configuration, About profibus pa -1, Outline -1, Internal structure of the eja -1, Logical structure of each block -1, Wiring system configuration -1

IM 01C22T03-00E

3-1

3. ABOUT PROFIBUS PA

3.

ABOUT PROFIBUS PA

3.1 Outline

PROFIBUS PA is a widely used bi-directional digital

communication protocol that enables the implementation

of technologically advanced process control systems. The

EJA Series PROFIBUS PA communication type meets

the specifications of PROFIBUS Nutzerorganisation e.V.

and is interoperable with devices from Yokogawa and

other manufacturers.

3.2 Internal Structure of the EJA

The EJA contains four blocks that share the following

functions:

(1) Physical block

• Manages the status of EJA hardware.

(2) Transducer block

• Converts sensor output to pressure signals and

transfers to AI function block.

• Carries out square root extraction.

(3) AI1 function block

• Conditions raw data from the transducer block.

• Outputs differential pressure signals.

• Carries out scaling and damping extraction.

(4) AI2 function block

• Outputs static pressure signals.

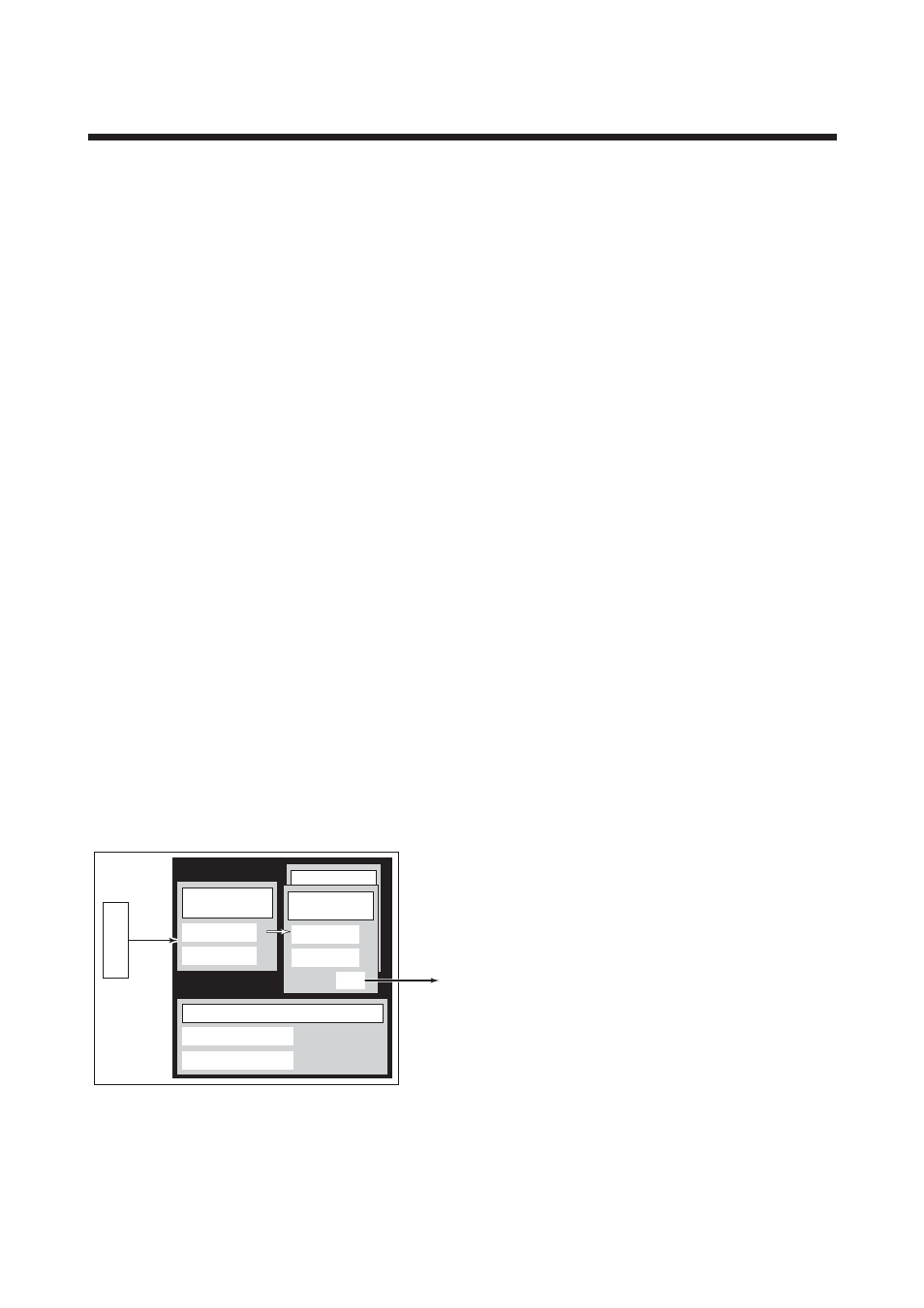

3.3 Logical Structure of Each

Block

EJA

Sensor

input

Physical block

Block tag

Parameters

AI function

block

Output

AI function

block

Block tag

OUT

Parameters

Transducer

block

Block tag

Parameters

Sensor

F0301.EPS

Figure 3.1 Logical Structure of Each Block

The parameters shown in Figure 3.1 must be set before

starting operation.

3.4 Wiring System Configuration

The number of devices that can be connected to a

single bus and the cable length vary depending on

system design. When constructing systems, both the

basic and overall design must be carefully considered

to allow device performance to be fully exhibited.