4 self-diagnostics, 1 checking for problems, 1) identify problems with hart communicator – Yokogawa EJA115 User Manual

Page 27: Self-diagnostics -20, Checking for problems -20, Identify problems with hart communicator -20, Error messages — hart communicator

IM 01C22T01-01E

2-20

2. HART COMMUNICATOR OPERATION

2.4 Self-Diagnostics

2.4.1 Checking for Problems

(1) Identify Problems with HART Communica-

tor

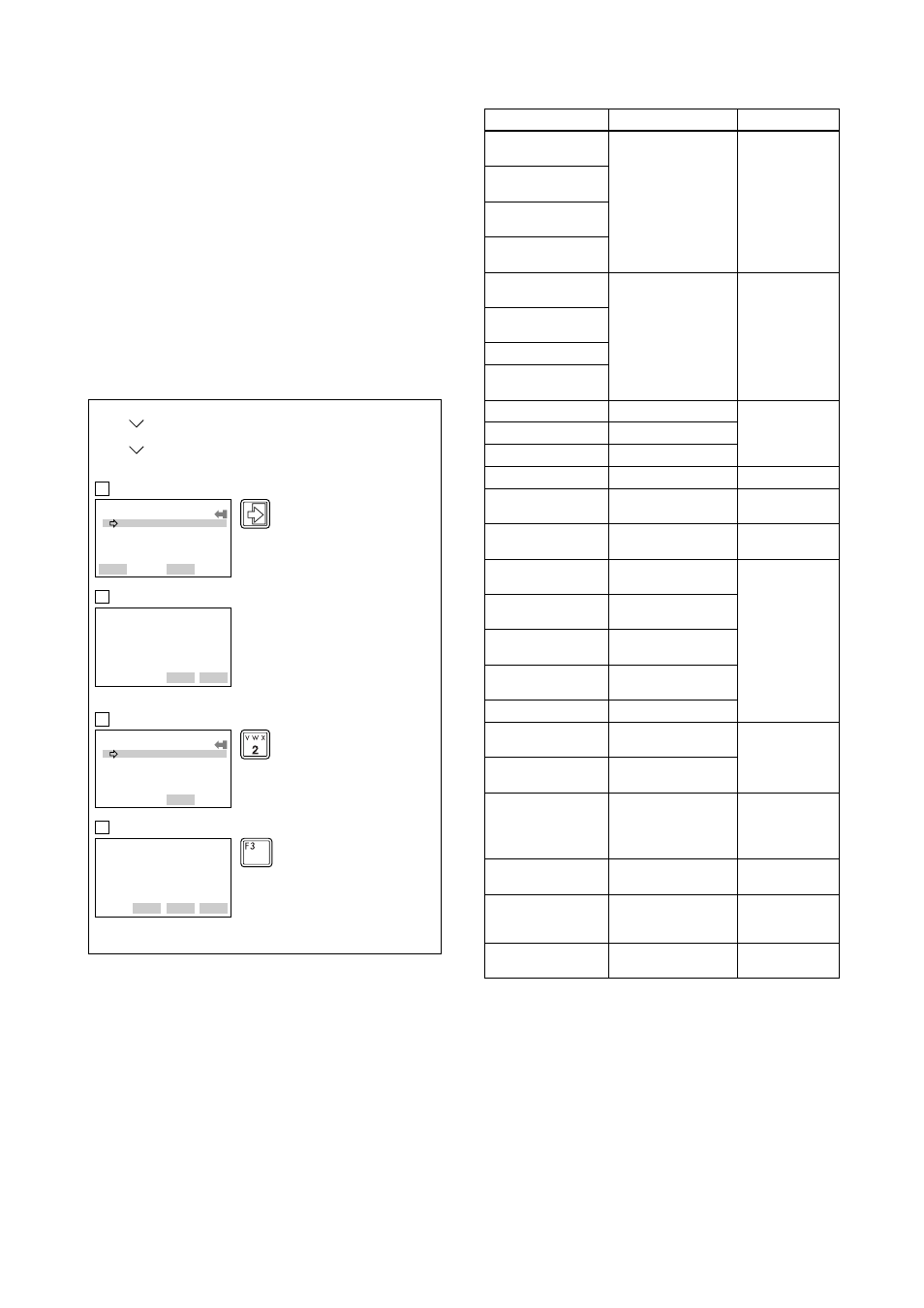

Self-diagnostics of the transmitter and check of

incorrect data setting can be carried out with the

HART communicator. There are two methods for self-

diagnosis of the transmitter, self-diagnosis for every

transmission and manually executing the SELF TEST

command. When an error message appears, follow

“ERROR MESSAGES”.

Diagnostic by “self test”

1

F0242.EPS

Call up the Test/Status, and select

Self test.

EJA:

Test/status

1 Self test

2 Status

HELP

SET

HOME

OK

EJA:

Self test OK

DEL

SET

ABORT

OK

2

If there is no error detected, Self

test OK will be displayed.

When an error occurs, an error

message appears, and the results

of self-diagnosis appear in the

Status item.

1. Device setup

2. Diag/Service

1. Test/Status

1

Call up the Status item.

If there is no error, the result of

diagnostics is indicated as OFF. If

ON is indicated, a countermeasure

for that error is necessary.

EJA:

Test/status

1 Self test

2 Status

HELP

SET

HOME

OK

EJA:

Status

Field device not

installed

OFF

DEL

PREV

NEXT

EXIT

2

(NEXT)

• Error Messages — HART Communicator

T0205.EPS

Error Message

Probable Cause

Countermeasure

Pressure sensor

error

Temp (Cap) sensor

error

EEPROM (Cap)

failure

Sensor board not

initialized

Temp (Amp) sensor

error

EEPROM (Amp)

failure

Dev id not entered

CPU board not

initialized

Invalid Selection

Parameter Too High

Parameter Too Low

Incorrect Byte Count

In Write Protect

Mode

Set to Nearest

Possible Value

Lower Range Value

too High

Lower Range Value

too Low

Upper Range Value

too High

Upper Range Value

too Low

Span too Small

Applied Process

Value too High

Applied process

Value too Low

New LRV pushed

URV Over Sensor

Limit

Excess Correction

Attempted

In Proper Current

Mode

In Multidrop Mode

Capsule problem

Amplifier problem

Set value is too high.

Set value is too low.

Operation is set in the

Write Protect mode.

Value is set to a

nearest possible value.

LRV set point is too

high.

LRV set point is too

low.

URV set point is too

high.

URV set point is too

low.

Set span is too small.

Applied pressure is

too high.

Applied pressure is

too low.

The shift of URV

according to the new

LRV setting exceeds

USL.

Amount of correction

is too much.

The fixed current

mode is desired but

not set in that mode.

Operation is set in

the multi-drop mode.

Replace capsule

when error keeps

appearing even

after restart.

Replace

amplifier.

Change the

setting.

Change the

range.

—

—

—

—

Adjust the

applied pressure.

Change the

setting within the

range of USL.

Adjust the amount

of correction.

Set in the fixed

current mode.