13) sensor trim, 13) test output -13 (14) sensor trim -13 – Yokogawa EJA115 User Manual

Page 20

IM 01C22T01-01E

2-13

2. HART COMMUNICATOR OPERATION

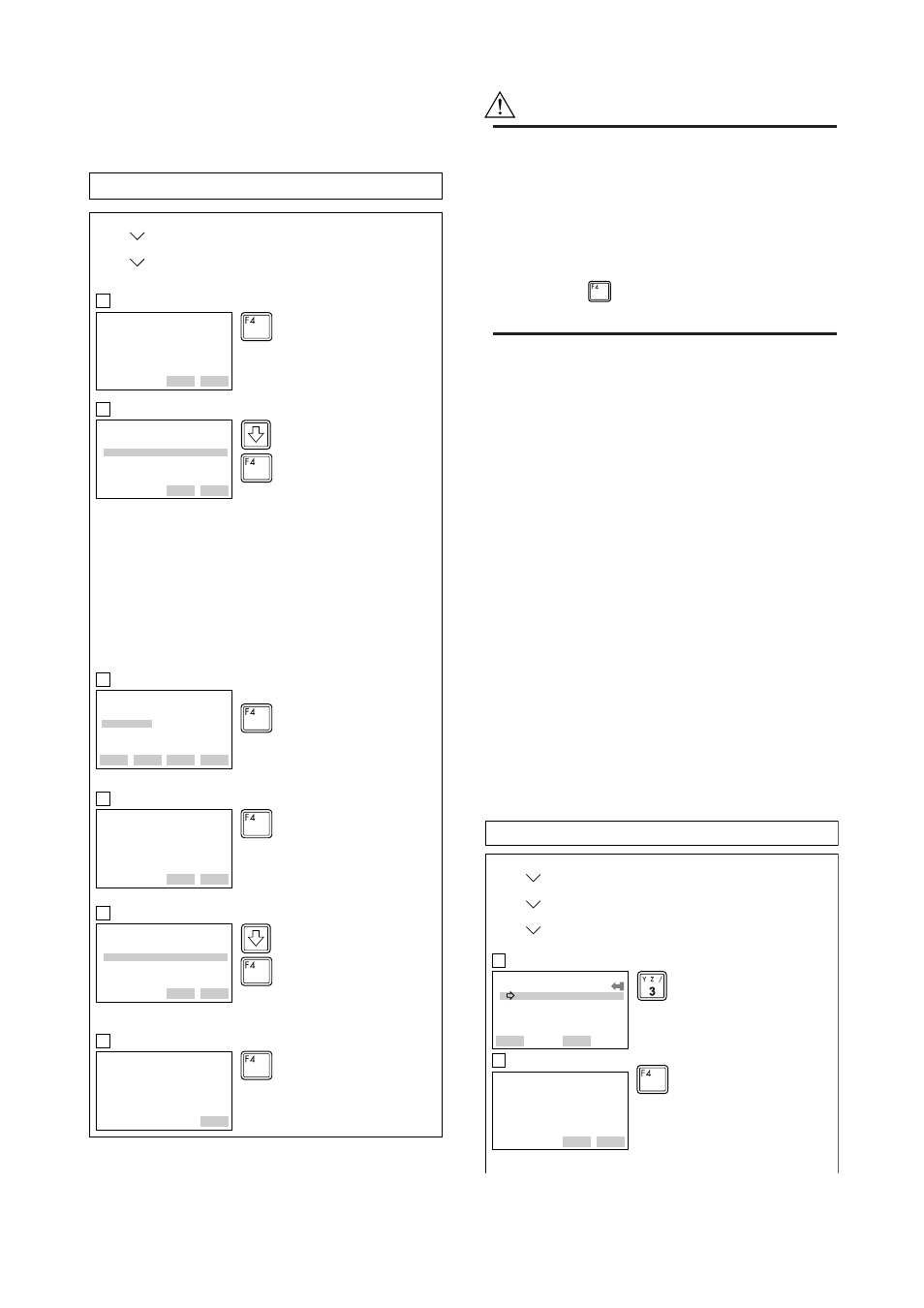

(13) Test Output

This feature can be used to output a fixed current from

3.2 mA (–5%) to 21.6 mA (110%) for loop checks.

1

F0227.EPS

Set the control loop in manual

mode, and press OK (F4).

EJA:

WARN-loop should be

removed from

automatic control

DEL

SET

ABORT

OK

EJA:

Choose analog output

level

1 4mA

2 20mA

3 Other

4 End

DEL

SET

ABORT

ENTER

2

Select Other, and press ENTER

(F4).

Supplementary explanation.

1. 4 mA:

Outputs a 4 mA current signal

2. 20 mA:

Outputs a 20 mA current signal

3. Other:

Sets a desired output using the

alphanumeric keys

4. End: Exits

EJA:

Output

4.000

HELP

DEL

ABORT

ENTER

3

Enter 12, and press ENTER (F4).

A fixed current of 12 mA is output.

EJA:

Fld dev output is

fixed at 12.000 mA

DEL

ABORT

4

Press OK (F4).

HELP

SEND

OK

×

2

(ENTER)

×

3

(ENTER)

(ENTER)

(OK)

(OK)

‘1 2’

(OK)

EJA:

Choose analog output

level

1 4mA

2 20mA

3 Other

4 End

DEL

ABORT

5

To finish the loop test, select End,

and press ENTER (F4).

HELP

SEND

ENTER

EJA:

NOTE-loop may be

returned to automatic

control

DEL

ESC

6

Press OK (F4).

HELP

SEND

OK

Example: To output 12 mA (50%)

1. Device setup

2. Diag/Service

2. Loop test

CAUTION

1. Test output is held for approximately 10

minutes, and then released automatically

after the time has elapsed. Even if the HART

Communicator power supply is turned off or

the communication cable is disconnected

during test output, it is held for approximately

10 minutes.

2. Press the

(OK) key to release test output

immediately.

(14) Sensor Trim

Each DPharp EJA Series Transmitter is factory

characterized. Factory characterization is the process of

comparing a known pressure input with the output of

each transmitter sensor module over the entire pressure

and temperature operating range. During the character-

ization process, this comparison information is stored

in the transmitter EEPROM. In operation, the transmit-

ter uses this factory-stored curve to produce a process

variable output (PV), in engineering units, dependent

on the pressure input. The sensor trim calibration

procedure allows you to make corrections to the

calculated process variable.

There are two ways to trim the sensor: full sensor trim

and zero trim. A full sensor trim is a two point process,

in which two accurate end-point pressures are applied

(equal to or greater than the range values), and all

output is linearized between them. A zero trim is a

one-point adjustment typically used to compensate for

mounting position effects or zero shifts caused by static

pressure. (See section 1.1.1)

1

F02281.EPS

Select the Lower Sensor trim.

EJA:

Sensor trim

1 Zero trim

2 Pres

3 Lower sensor trim

4 Upper sensor trim

5 Sensor trim points

HELP

SET

HOME

OK

EJA:

Apply low pressure

DEL

SET

ABORT

OK

2

Apply a standard pressure of 1000

mmH

2

O to the transmitter. After

obtaining a stable pressure, press

OK (F4).

(OK)

Example 1: For the range of 1000 to 3000 mmH

2

O

1. Device setup

2. Diag/Service

3. Calibration

3. Sensor Trim