Figure 6, Figure 7, Tech n ical p ape r – PCT Engineered Comparison of UV and EB Technology for Printing and Packaging Applications User Manual

Page 6

32 RADTECH REPORT SEPTEMBER/OCTOBER 2008

Tech

n

ical P

ape

r

adhesives for printing and packaging

applications. This may be due in part

to a declining cost of photoinitiators

following the expiration of some key

patents. Comparison of UV and EB

operating costs is, therefore, more

related to the equipment itself.

With mercury-based UV lamps,

about one-half of the electrical energy

input is converted to UV energy. The

remaining energy is lost as heat. Some

additional electrical energy is consumed

in the operation of blowers for air

cooling which is most common for

printing and packaging applications.

EB equipment is more efficient at

converting electrical energy into curing

energy compared to UV equipment.

Some additional electrical energy is

needed for vacuum pumps and water

cooling of the emitter. Another

operating cost of EB is nitrogen, which

is needed to inert the curing zone for

most ink and coating applications.

A detailed comparison of operating

costs for UV and EB can be made for a

specific application. Often, this analysis

will show similar costs for UV and EB

and significant savings compared to

thermal curing.

Inerting

Free radical curing—commonly

used in both UV and EB applications—

is inhibited by atmospheric oxygen.

Oxygen itself exists in a biradical

(triplet) state and will rapidly diffuse

into the surface of an ink or coating

and terminate the polymerization

(curing) reaction.

UV formulations can be designed to

cure in an air atmosphere. In air curing

systems, the radical initiation

essentially outcompetes the oxygen

termination. This is possible because of

the high surface irradiance illustrated

in Figure 1. The ability to UV cure in

air can be advantageous for some

printing and packaging applications. In

particular, air curing is very important

in sheet-fed printing. Sheet-fed

equipment is very difficult to inert

because of the mechanisms present to

transport the sheet through the press.

In some cases, it may be advantageous

to inert UV-cured systems. Inerting can

greatly accelerate UV curing which can

increase line speed, reduce the number

of lamps, and/or reduce the amount of

photoinitiator needed for curing.

Inerting may be an attractive option for

food packing applications in which

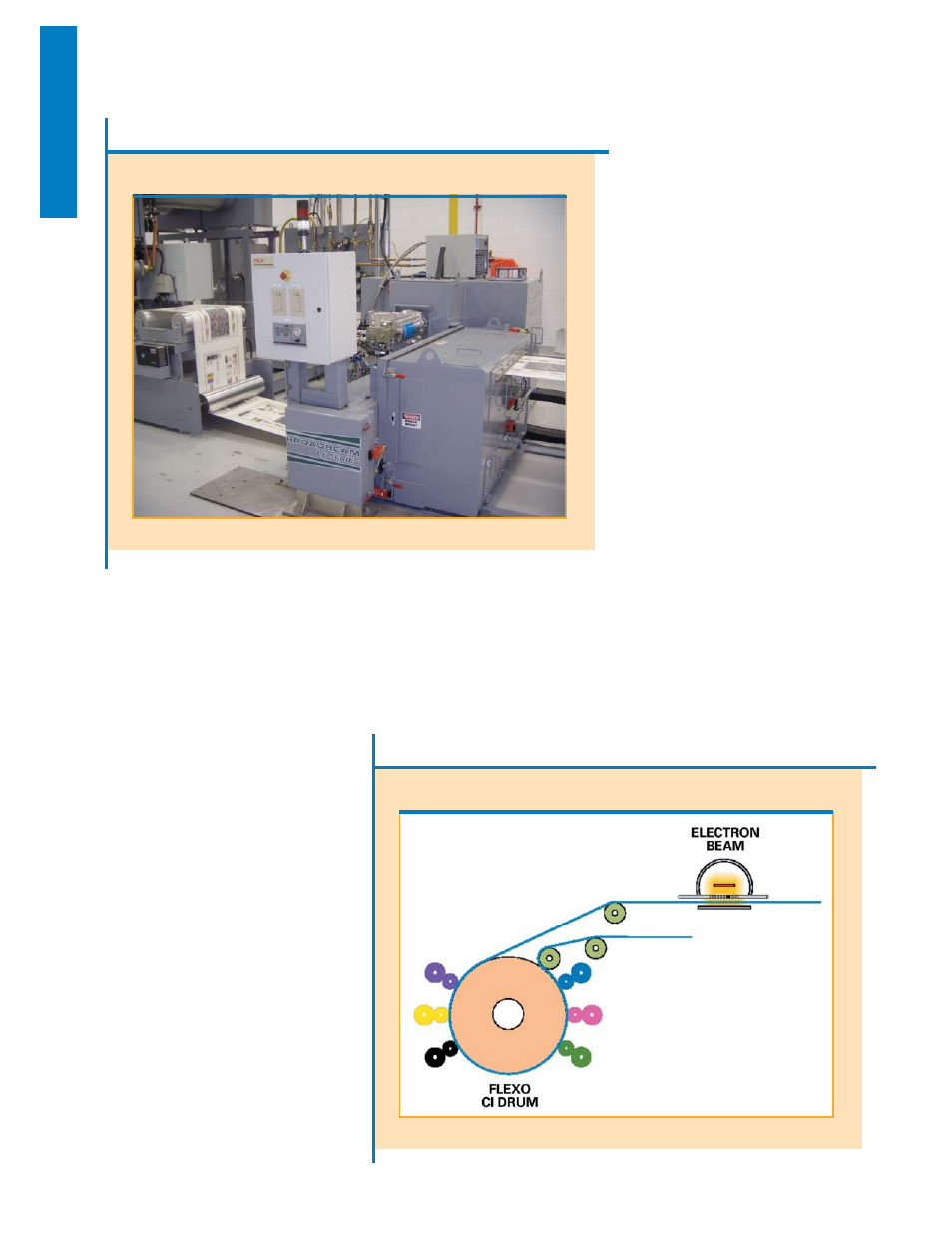

Figure 6

Low-voltage EB equipment on web offset press

Figure 7

WetFlex™ EB flexographic printing