Figure 5, Figure 4, Tech n ical p ape r – PCT Engineered Comparison of UV and EB Technology for Printing and Packaging Applications User Manual

Page 5

SEPTEMBER/OCTOBER 2008 RADTECH REPORT 31

Tech

n

ical P

ape

r

method for flexible packaging since it

provides superior handling of extensible

film substrates.

New permanent vacuum modular

low-voltage equipment makes it

possible to consider interstation EB

curing. So far this does not appear to

be a commercial reality, but it is an

area for potential future development.

Capital Costs

The cost of a UV lamp for a narrow

application is relatively low. For many

printing and packing applications, a

single lamp operating at input powers

up to 600 w/in will cure a single ink or

topcoat up to about 300 to 400 feet/

minute. Installation of six or more

press stations running at 800 to 1,000

ft/minute could require 12 or more lamps.

Original industrial EB curing units

typically cost more than $1 million.

Modern low-voltage equipment has

reduced the cost by at least half. A

single EB unit is capable of delivering

30 kGy (3 Mrad) cure dose at greater

than 1,000 ft/min. As discussed above,

multiple wet-trapped ink and coating

layers may be cured with this single

unit. EB curing units are easily sized

for wide-web (>60 inches) printing

applications.

Even though a single UV lamp is

significantly lower in cost than an EB

unit, when one considers the total

capital cost of a wide, high-speed line,

EB may be comparable or lower in cost

than a multilamp UV installation.

Operating Costs

One of the primary advantages of UV

and EB curing is the reduced energy

costs compared to thermal drying

ovens.

12

Another major component of

the operating expense is the cost of the

inks, coatings and adhesives. When

comparisons are made based on the

“solids” that are applied, it may be seen

that the cost of UV/EB materials

(which are near 100% solids) may not

command a significant premium.

In general, there does not tend to

be a significant difference in cost

between UV and EB inks, coatings and

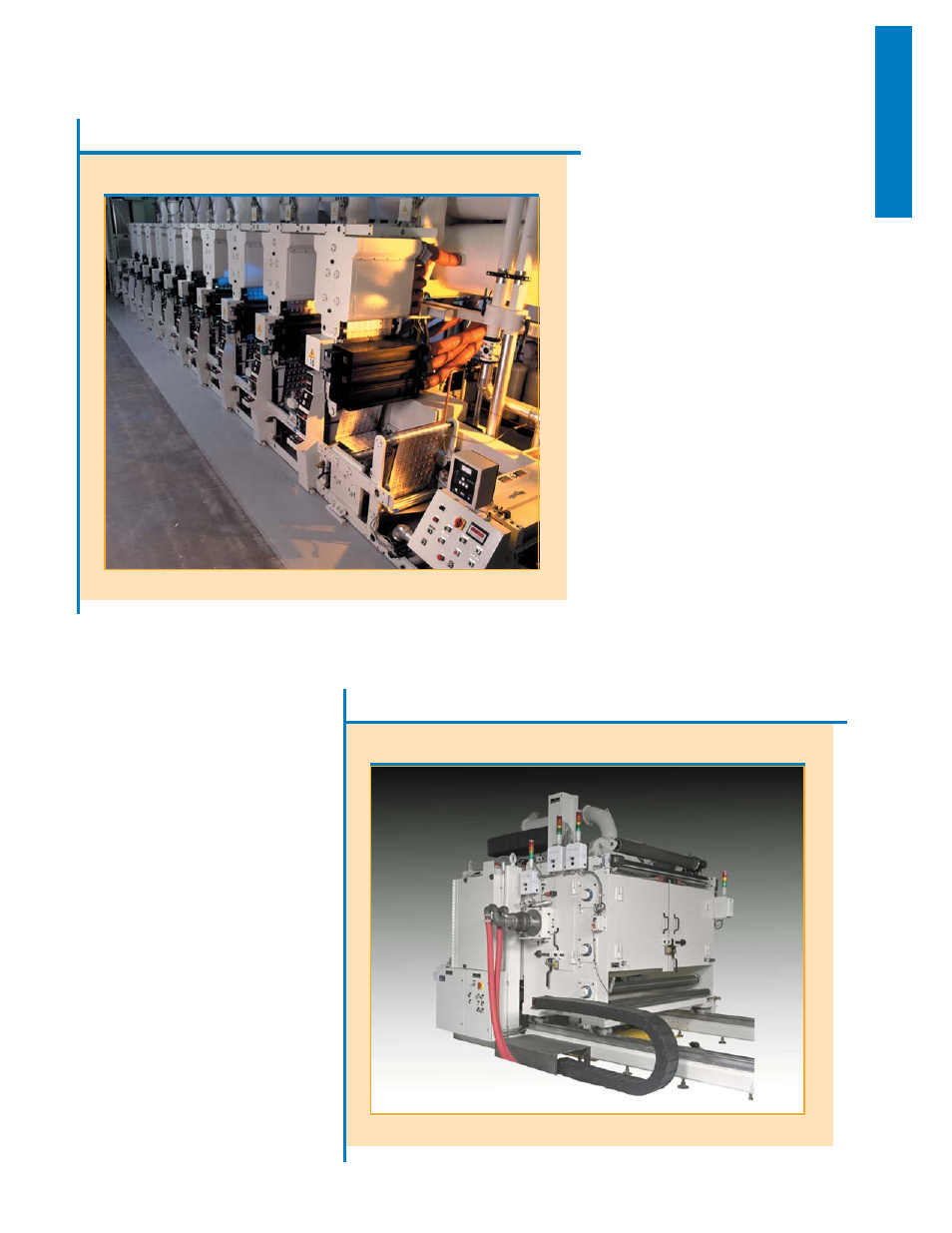

Figure 5

Industrial EB processing equipment

Figure 4

Interstation UV installation on a flexo press