Figure 3, Tech n ical p ape r, Uv lamp system components – PCT Engineered Comparison of UV and EB Technology for Printing and Packaging Applications User Manual

Page 4

30 RADTECH REPORT SEPTEMBER/OCTOBER 2008

Tech

n

ical P

ape

r

for printing and packaging applications

is completely shielded and interlocked

to contain the damaging UV energy. In

most cases, no special personal

protective equipment (PPE) is

required other than the PPE normally

recommended in the printing and

packing production plant environment.

In addition to UV energy hazards,

mercury lamps also operate at very high

temperatures. Hazards from thermal

skin burns are minimized by the lamp

housing which surrounds the bulb.

Electrons from EB equipment

present limited hazards because of

their limited ability to penetrate. The

main hazard of EB is the secondary

X-rays that are generated when

electrons interact with matter,

including metal components within the

EB reaction chamber. Modern EB

equipment is completely self-shielded.

The shielding is interlocked and

monitors are present which will shut

down the EB unit if X-rays are

detected. Radiation is not present if

the machine is not energized. Most EB

installations will include a person

trained as a Radiation Safety Officer

(RSO). Periodic radiation surveys are

typically conducted to supplement the

continuous monitoring of the equipment.

Worker exposures above normal

environmental background levels are

extremely rare.

Both UV and EB equipment are

very safe to operate and there are no

significant drivers for selection of

one technology over the other based

on safety.

Equipment Size

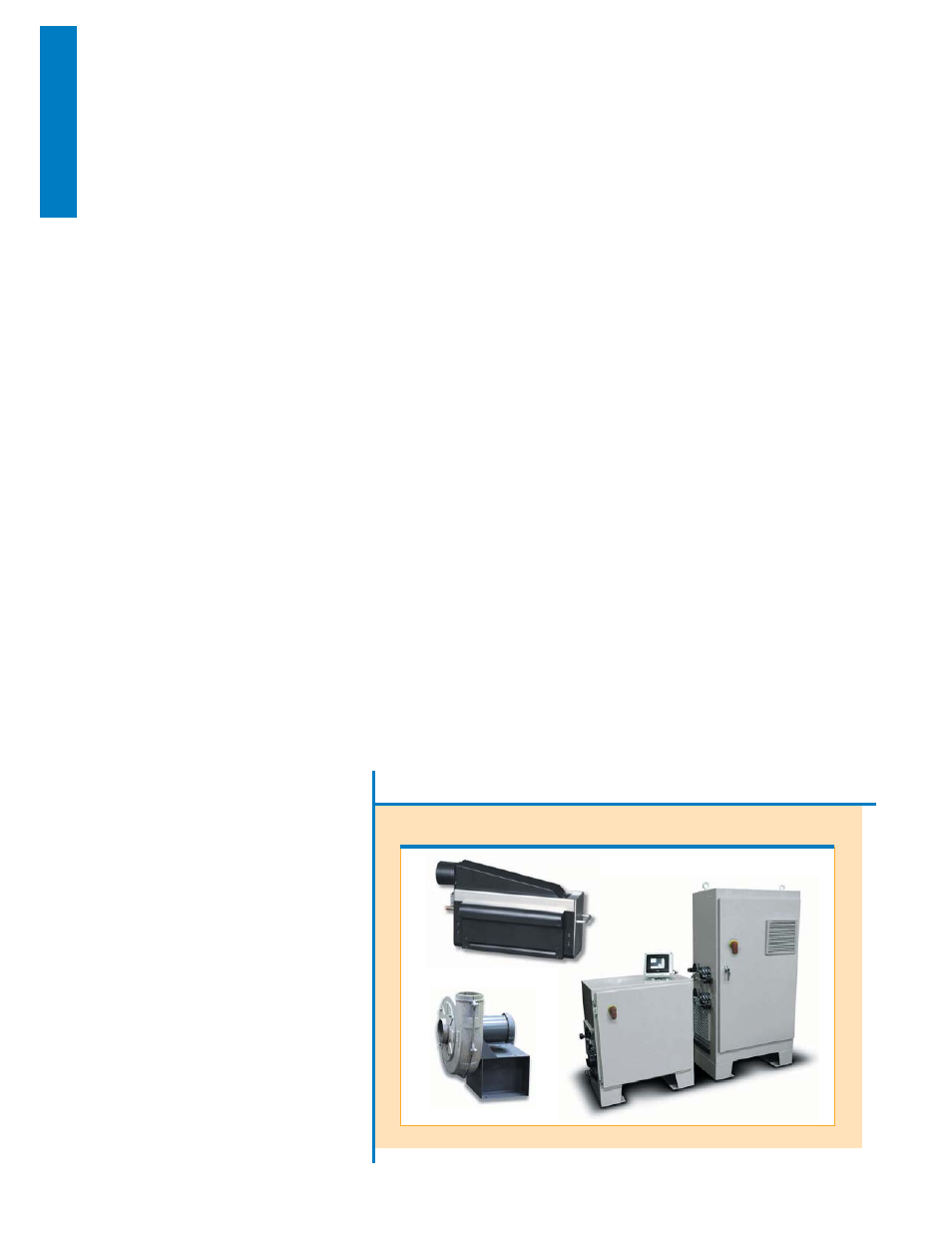

The components of typical UV

curing systems include the lamp,

power supply, air handling equipment

(blowers) and control panels. These

components are pictured in Figure 3.

The lamp (which includes the bulb,

reflectors, shielding and heat

management components) is relatively

compact and lends itself well to

interstation installation between

printing decks (Figure 4). Interstation

installation allows curing of each ink

color. Multiple colors are combined in a

“dry trapping” process to create the

graphic image. Interstation curing also

allows press designs in which the

printed side of the web may be turned

up against an idler roll between stations.

Original industrial EB equipment

was quite large (Figure 5). Modern

low-voltage EB equipment can be less

than one-half the size of original

industrial EB equipment. In spite of

the size reduction, it is still not

practical to use this equipment for

interstation curing; though the smaller

footprint is still very attractive for

end-of-press installations.

9

The most

common installation of this type of

equipment is at the end of a web offset

press used for the production of

folding cartons (Figure 6). Offset

(lithographic) printing uses paste inks

which are designed to be “wet trapped”

without any interstation drying. This

lends itself well to EB curing at the end

of the press with a single EB unit. The

development of modern low-voltage

EB equipment coincides nicely with

the development of web offset presses

incorporating variable repeat length

technology. This has facilitated

expansion of web-offset printing

technology beyond folding cartons to

flexible packaging and labels.

10

Flexographic printing utilizes liquid

inks so, historically, it has been necessary

to use interstation curing to dry trap

inks. This interstation curing has been

achieved by thermal or UV curing

technology. Recently new technology

(Wetflex™) has been developed to wet

trap flexographic inks.

11

Wet trapping

allows interstation curing to be

eliminated and replaced with a single EB

curing station at the end of the press

(Figure 7). This technology has also

been shown to give extremely low dot

gain which results in superior quality

printing. It should be noted that Wetflex

is limited to central impression (CI) flexo

press configurations in which the printed

side of the web does not contact idler

rolls until after EB curing. Flexographic

CI printing is often the preferred

Figure 3

UV Lamp system components

Photos courtesy of Mark Andy Inc.

Power Cabinet

UV Lamp Cassette

Blower