Figure 2, Tech n ical p ape r, Depth/dose profiles for low-voltage eb – PCT Engineered Comparison of UV and EB Technology for Printing and Packaging Applications User Manual

Page 3

SEPTEMBER/OCTOBER 2008 RADTECH REPORT 29

Tech

n

ical P

ape

r

material. Clear materials are “optically

thin.” In general, UV energy can easily

penetrate clear materials such as

overprint coatings and clear films.

Even if a portion of the UV spectrum is

blocked by a clear layer (such as a PET

film), effective curing can usually be

achieved throughout the thickness of

the layer by selecting the proper

photoinitiator package. Penetration of

UV energy becomes a significant

challenge when curing “optically thick”

pigmented materials. Many pigmented

printing inks can be UV cured as long

as the pigment loading and/or ink

thicknesses remain relatively low. It is

typically difficult to UV cure through

printed, white opaque, heavy black or

metallic inks.

3

Penetration of UV energy can be

controlled, to a degree, by the peak

irradiance of the lamp. The peak

irradiance depends on the power and

the focus of the lamp system. High-

power, tightly focused lamps can

improve curing of some higher OD ink

layers

4

; however, the OD can reach a

point in which curing is not possible

with any commercial lamp system.

EB penetration depends upon the

mass density and thickness of the

material. Electrons penetrate more

deeply through lower density materials

(such as polyolefin films and paper)

compared to high-density materials

such as metal foils. Mass density and

thickness taken together may be

expressed as the basis weight of the

material. For most printing and

packaging applications, the basis

weight is expressed in units of grams/

meter

2

or pounds/3000 ft

2

. Electrons

are “color blind” and penetration is not

affected by pigments and opaque

substrates. EB is ideal for curing high-

opacity white, black and metallic ink

layers. EB can also penetrate reverse

printed, metalized and white films as

well as papers to instantly cure adhesive

layers for laminating applications.

5

EB penetration is controlled by the

accelerating potential (voltage) of the

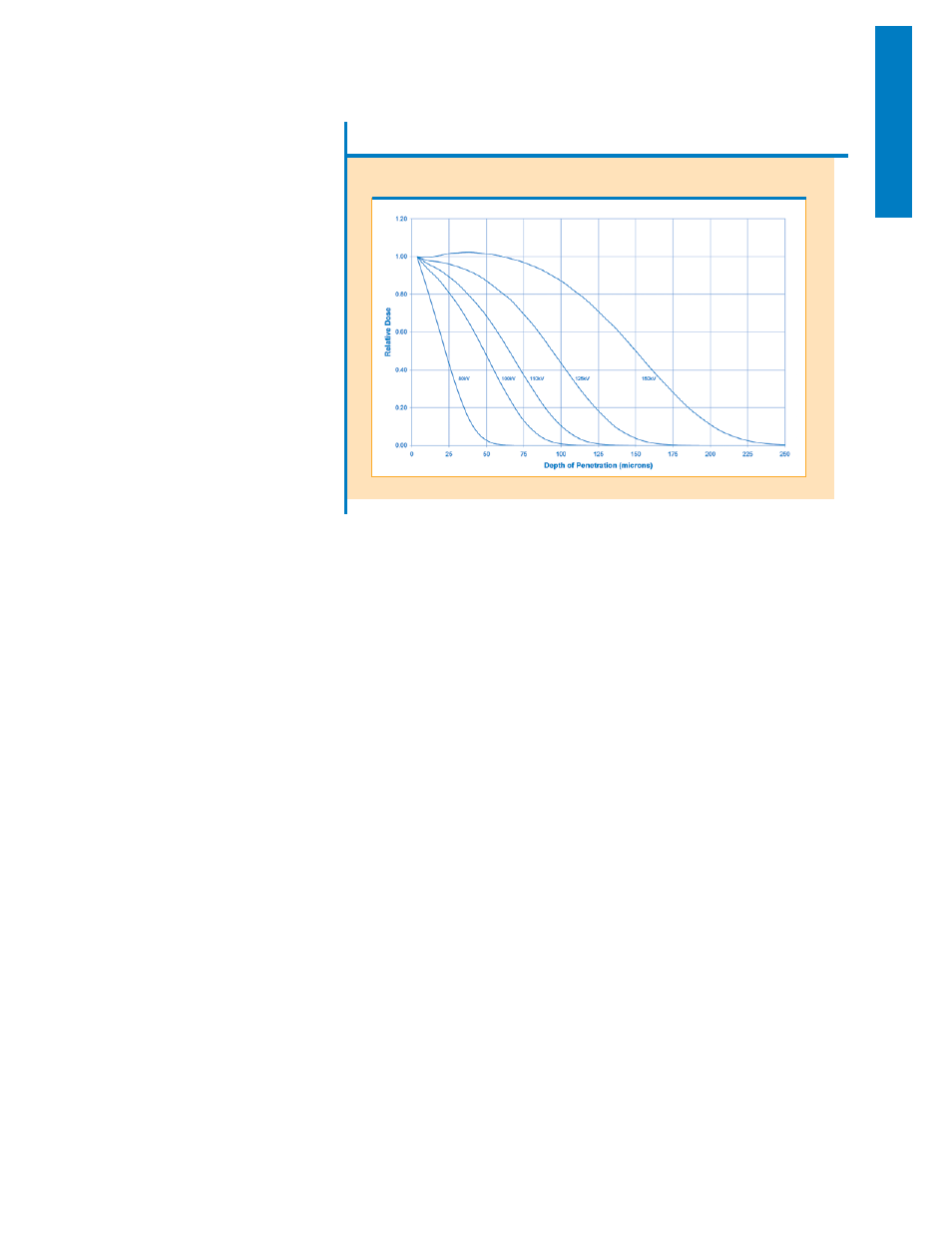

EB equipment. Figure 2 shows EB

penetration as a function of voltage.

Low-voltage EB equipment operating

from about 70 to 125 kV is ideal for

curing thin inks, coatings and film

layers used in most printing and

packaging applications.

6

UV and EB Equipment

The most common UV equipment

for printing and packaging applications

is based on medium-pressure mercury

lamps. These lamps may be energized

through electrodes (arc type) or by

microwaves (electrodeless). Medium-

pressure mercury lamps produce a

characteristic UV-emission spectrum

with multiple peaks between 250 nm to

450 nm. Mercury lamps may also be

doped with various elements to shift the

spectral output to better match the inks,

coating or adhesive that is being cured.

Other types of lamps, such as

xenon lamps, are available but are not

commonly used for printing and

packaging applications. UV-light emitting

diodes (LEDs) are now available with

higher powers, but their use is still

quite limited in printing and packaging

materials.

7

EB equipment is based on electrically

operated filaments and grids contained

within a vacuum chamber. The

electrons are accelerated through a

window/foil structure to reach the

substrate at atmospheric pressure.

EB equipment includes “curtain” and

scanning type units. The curtain type

is used almost exclusively for printing

and packaging applications. Most EB

equipment includes an active pumping

system to maintain a vacuum in the

electron gun chamber. A new

generation of modular 10- and 16-inch

wide EB equipment based on

permanent vacuum emitters is also

now available. There have been some

initial investigations incorporating

these modular emitters in printing

applications.

8

UV and EB Equipment Safety

UV lamps used in printing and

packaging applications produce

significant short wavelength UV

output. This intense UV energy can

cause skin and eye damage.

Commercial UV lamp equipment used

Figure 2

Depth/dose profiles for low-voltage EB