New product introduction, Series e, Control reliable – Ross Controls CATEGORY 4 - 3_2 VALVES SERIES DM2 C, E User Manual

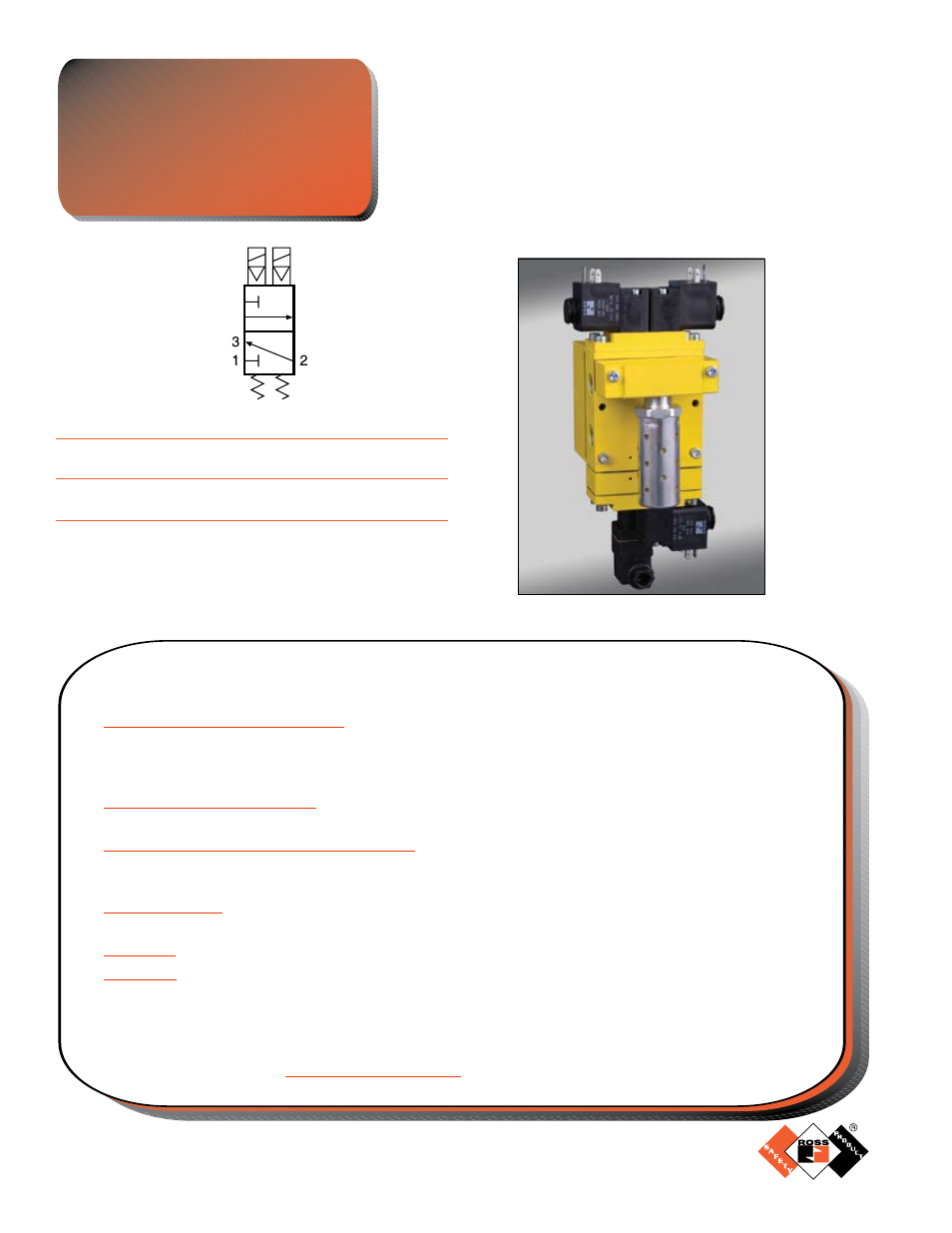

Page 6: Double valve with dynamic, Size 2

www.rosscontrols.com

New Product

Introduction

Simplified

Schematic

Category 4 applications - e.g. Air Dump/Release.

FEATURES:

APPLICATIONS:

Dynamic Monitoring with Memory:

•

Memory, monitoring, and air flow control functions are integrated into two

identical valve elements for CAT 4 applications, except control of the clutch/brake mechanism on mechanical

power press. Valves lockout if asynchronous movement of valve elements occurs during actuation or de-

actuation, resulting in a residual outlet pressure of less than 1% of supply.

An action is required for reset

•

: cannot be reset by removing and re-applying supply pressure or electrical

power. Reset can only be accomplished by the integrated electrical (solenoid) reset.

Basic 3/2 Normally Closed Valve Function:

•

Dirt tolerant, wear compensating poppet design for quick

response and high flow capacity. Teflon back-up rings on pistons to enhance valve endurance – operates with

or without inline lubrication.

Status Indicator:

•

Includes a pressure switch with both NO & NC contacts to provide status feedback to the

control system indicating whether the valve is in the lockout or ready-to-run condition.

Silencers:

•

All models include high flow, clog resistant silencers.

Mounting:

•

Inline mounted – with BSPP or NPT pipe threads. Inlet and outlet ports on both sides provide for

flexible piping (plugs for unused ports included).

DM

2

®

Series

E

Control Reliable

Double Valve with Dynamic

Monitoring & Memory

Size 2

Port Size

C

V

Weight

Model Number* In-Out Exh. In-Out Out-Exh. lb (Kg)

DM2ENA20**21 1/4

1/2 1.34 2.43 5.6 (2.43)

DM2ENA21**21 3/8

1/2 1.92 2.43 5.6 (2.43)

* NPT port threads. For BSPP threads replace “N” in the model

number with a “D”.

** Insert voltage code:

“A” = 24 volts DC, “B” = 110 volts AC, “C” = 220 volts AC,

“D” = 12 volts DC.

This valve is not designed for controlling clutch/brake mechanisms on mechanical power presses.