Overview of dm2 double valve function, Overview of dm, Series d double valve function – Ross Controls 3_2 VALVES SERIES DM2 D User Manual

Page 8

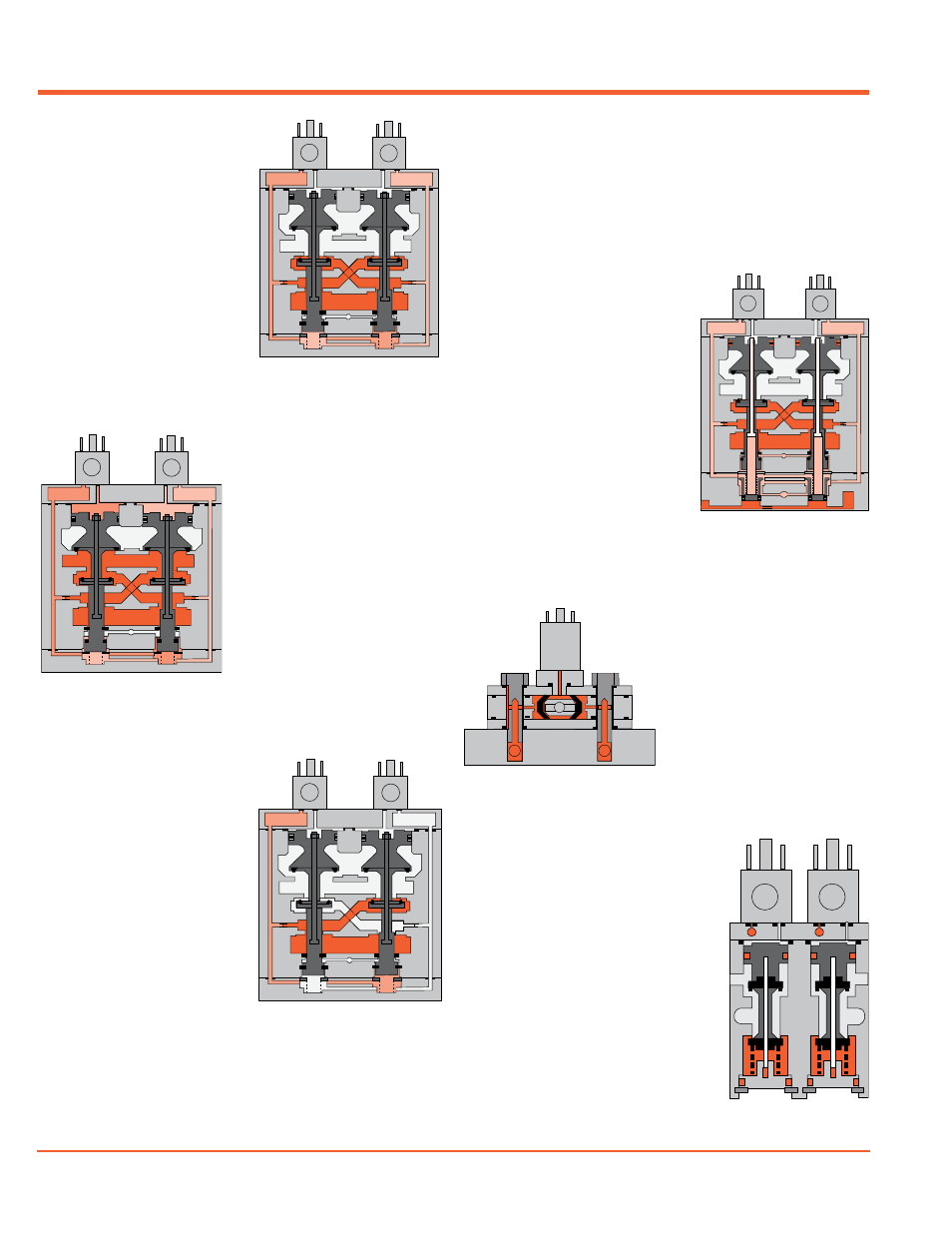

Valve de-actuated:

The flow of inlet air pressure

into the crossover passages

is restricted by the size of the

passage between the stem and

the valve body opening. Flow is

sufficient to quickly pressurize

pilot supply/timing chambers A

and B. The inlet poppets prevent

air flow from crossover passages

into the outlet chamber. Air pres-

sure acting on the inlet poppets

and return pistons securely hold

the valve elements in the closed

position. (Air passages shown

out of position and reset adapter

omitted for clarity.)

Valve actuated:

Energizing the pilot valves

simultaneously applies pres-

sure to both pistons, forcing the

internal parts to move to their

actuated (open) position, where

inlet air flow to crossover pas-

sages is fully open, inlet poppets

are fully open and exhaust pop-

pets are fully closed. The outlet

is then quickly pressurized, and

pressure in the inlet, crossovers,

outlet, and timing chambers are

quickly equalized.

De-energizing the pilots quickly

causes the valve elements

to return to the ready-to-run

position.

Valve loked-out:

Whenever the valve elements

operate in a sufficiently asynchro-

nous manner, either on actuation

or de-actuation, the valve will

move to a locked-out position.

In the locked-out position, one

crossover and its related timing

chamber will be exhausted, and

the other crossover and its related

timing chamber will be fully pres-

surized. The valve element (side

B) that is partially actuated has

pilot air available to fully actuate

it, but no air pressure on the

return piston to fully de-actuate

the valve element. Air pressure

in the crossover acts on the dif-

ferential of side B stem diameters

creating a latching force.

Side A is in a fully closed position, and has no pilot air available to

actuate, but has full pressure on the inlet poppet and return piston

to hold the element in the fully closed position.

Inlet air flow on side A into its crossover is restricted, and flows

through the open inlet poppet on side B, through the outlet into the

exhaust port, and from the exhaust port to atmosphere. Residual

pressure in the outlet is less than 1% of inlet pressure.

The return springs are limited in travel, and can only return the valve

elements to the intermediate (locked-out) position. Sufficient air

pressure acting on the return pistons is needed to return the valve

elements to a fully closed position.

Resetting the valve:

The valve will remain in the locked-

out position, even if the inlet air

supply is removed and re-applied. A

remote reset signal (air or electric),

or a manual push button actuation

must be applied to reset the valve.

Reset is accomplished by mo-

mentarily pressurizing the reset

port. Actuation of the reset piston

physically pushes the main valve el-

ements to their closed position. Inlet

air fully pressurizes the crossovers

and holds the inlet poppets on seat.

Actuation of the reset piston opens

the reset poppet, thereby, immedi-

ately exhausting pilot supply air, thus, preventing valve operation

during reset. (Reset adapter added to illustration.)

De-actuation of reset pistons

causes the reset poppets to

close and pilot supply to fully

pressurize.

Reset air pressure can be

applied by a remote 3/2 normally

closed valve, or from an optional

3/2 normally closed solenoid, or

a manual push button mounted

on the reset adapter.

Status indicator:

The status indicator pressure switch will

actuate when the main valve is operating

normally, and will de-actuate when the

main valve is in the locked-out position

or inlet pressure is removed. This device

is not part of the valve lockout function,

but, rather, only reports the status of

the main valve.

Size 12 and 30 valves require relatively

large pilots to actuate and de-actuate

the main valve elements. In order to

achieve extremely quick valve response

for such large pilots, a 2-stage solenoid

pilot system is incorporated into the

design. This keeps the electrical

current required to operate the pilots,

to a minimum.

Overview of DM

2®

Series D Double Valve Function

EXHAUST

T

T

T

T

INLET

OUTLET

EXHAUST

OUTLET

INLET

A

B

EXHAUST

T

T

T

T

INLET

OUTLET

EXHAUST

OUTLET

INLET

A

B

EXHAUST

OUTLET

INLET

A

B

A

B

EXHAUST

T

T

T

T

INLET

OUTLET

EXHAUST

OUTLET

INLET

A

B

Status indicator (optional)

in normal ready-to-run position

Valve actuated

Valve ready-to-run

Valve locked out

Valve being reset

Size 12 & 30 pilots

8

© 2010, ROSS CONTROLS.

All Rights Reserved.