Operating instructions – Ross Controls 3_2 VALVES SERIES DM2 D User Manual

Page 12

Operating Instructions

Start-up

Before start-up, the installation must be checked thoroughly by persons trained and experienced in the operation of pneumatic

equipment. Make sure that specifications given on the valve label (e.g. “max. operating pressure” and “electrical characteristics”)

will be in accordance with the operating specifications of the press. When operating pressure is initially applied, it may be

necessary to actuate the reset valve momentarily to move the main valve into the ready-to-run condition. Make sure that the

inlet supply and the exhaust path are not restricted. Operating pressure must comply with the minimum and maximum limits.

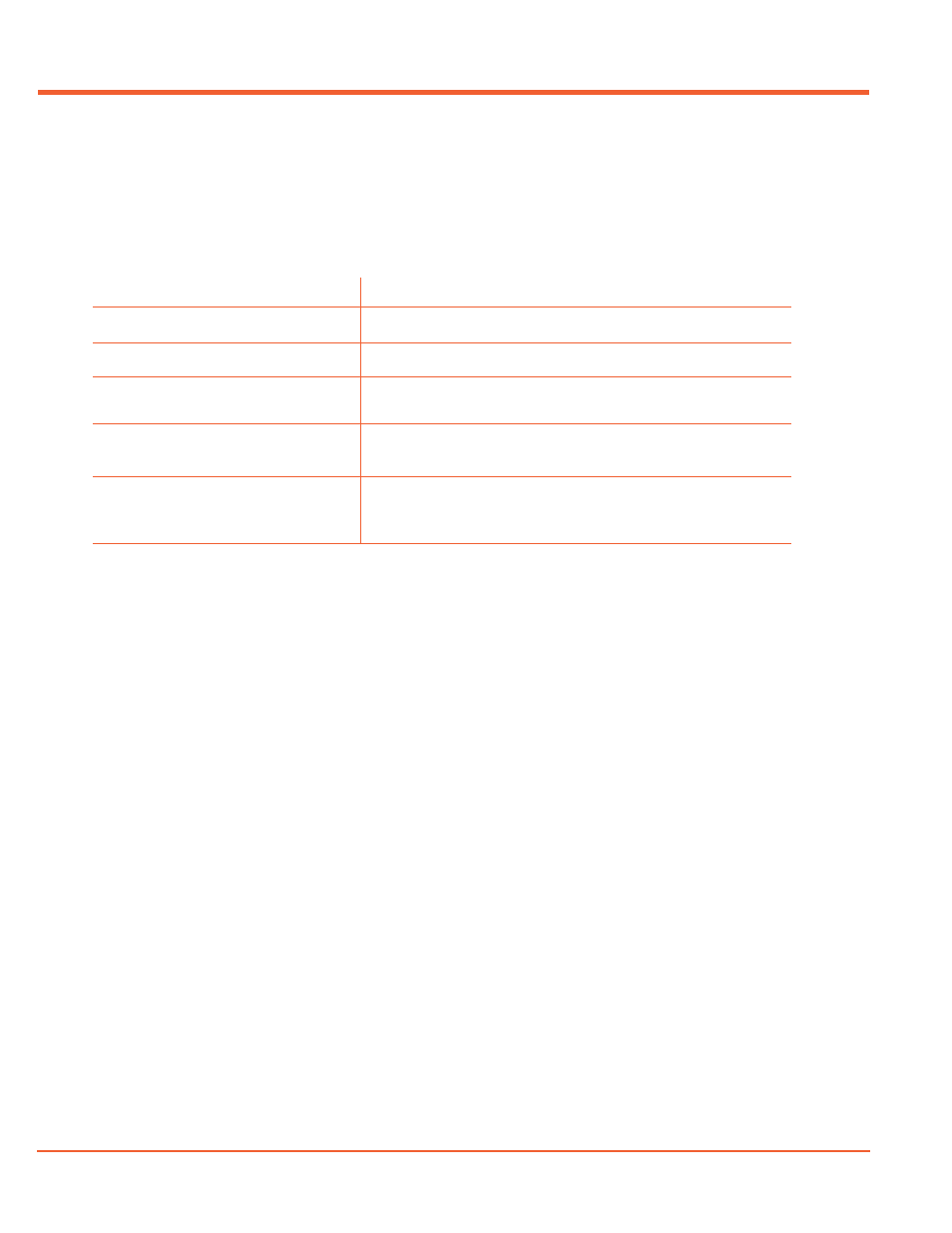

Functional test

Test

Result

1. Solenoid “A” actuated

Valve moves into lock-out mode, slight leakage at exhaust port 3

2. Solenoid “B” actuated

Valve moves into lock-out mode, slight leakage at exhaust port 3

3. Solenoids “A” and “B” actuated with

Valve operates properly

∆t < 0.1 s

4. Solenoids “A” and “B” actuated with

Valve moves into lock-out mode, slight leakage at exhaust port 3

∆t > 0.1 s

5. After lock-out, permanent signal on

Valve cannot be moved into ready-to-run mode

reset valve - solenoids “A” and “B”

or only “A” / only “B” actuated

Pressure test

After a valve lock-out, the double valve must be moved into the ready-

to-run position by using the reset valve. In general, if the valve is in

the lock-out mode and one or both of the solenoids are energized,

the valve should not reset with application or application and removal

of the reset signal. If the valve is in the ready-to-run mode after

the reset solenoid valve has been actuated momentarily, the valve

will function normally with application and removal of pilot solenoid

signal. However, if the valve elements cycle asynchronously, the

valve will go to the lock-out mode. Provided that both solenoids

are de-energized, removal of reset signal will return the valve to

the ready-to-run mode.

An additional test to perform:

• With the valve in the ready-to-run mode, exhaust and re-pressurize

the inlet port. The valve should remain in the ready-to-run mode.

• With the valve in the lock-out mode, exhaust and re-pressurize

the inlet port. The valve should remain in the lock-out mode.

Lock-outs

Any asynchronous movement between both piston elements for a

time period > 0.1 s will result in a lock-out of the valve. This can be

due to various causes, for instance:

• worn piston seals

• delayed response of the main valve elements due to dirt or

varnished lubricant

• electrical signals to solenoid incomplete or unable to maintain

proper voltage

• independent electrical signals to solenoids are not received

concurrently

• delayed response of solenoid pilots or booster pilots due to

damaged components, dirt, or varnished lubricant

• collection of excessive water or lubrication

Maintenance, Testing

Maintenance and testing procedures must follow the rules and

regulations set by the respective national work-safety institutions.

These procedures should only be performed by persons trained

and experienced in the use of pneumatic equipment. Regulations

generally require that maintenance and test procedures be performed

at least once a year.

Repair

ROSS would be happy to service this specialized double valve for you

at its factory repair center. Call your local ROSS office or distributor

(in the U.S. 1-800-GET-ROSS or +1-706-356-3708 outside the U.S.)

for information. If you service the valve yourself, be sure to turn off

electrical power to the valve, shut off the air supply, exhaust the air

in the system, and lock-out all power sources before beginning any

disassembly operation. Customers maintaining their own valves

should make sure that only original spare parts (as specified in the

ROSS parts lists) are used.

Pneumatic equipment should be repaired only by persons trained

and experienced in the repairing of such equipment, guided by

these operating instructions. Information about valve repair and/

or the exchange of a valve must be written down in the machine

operation documentation.

12

© 2010, ROSS CONTROLS.

All Rights Reserved.