Applications and safety category, Valve response charts, Application & safety category – Ross Controls 3_2 VALVES SERIES DM2 D User Manual

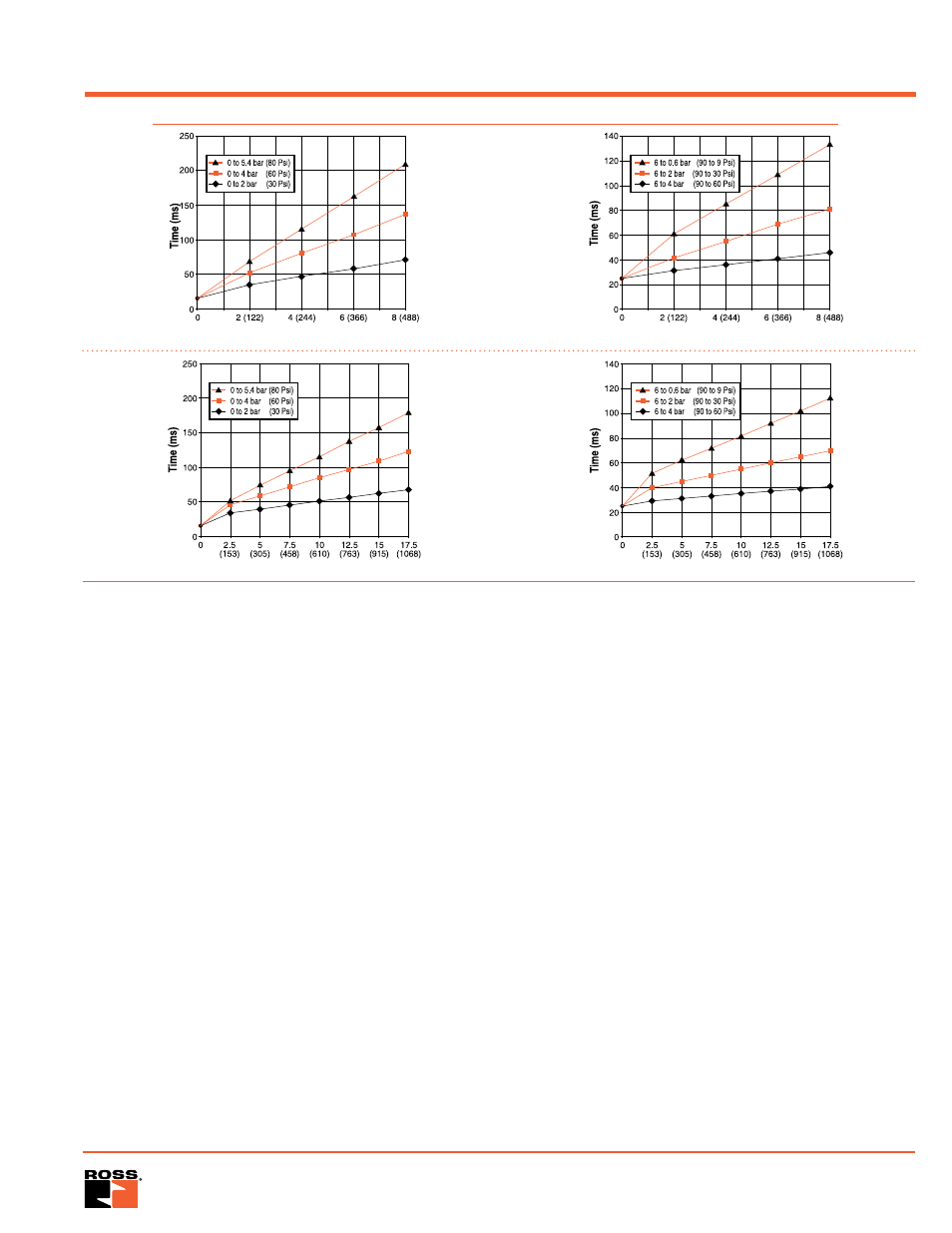

Page 11: Size 12, Size 30

Volume litres (cubic inches)

Volume litres (cubic inches)

Size 12

Volume litres (cubic inches)

Volume litres (cubic inches)

Size 30

1. General

The design features of the DM

2®

Series D are of considerable

importance to users of double valves, such as on mechanical

power press applications and other critical applications. This

is because the DM

2®

Series D is designed to meet the latest

standards requiring “control reliable”, “Category-3 & -4”, or

“dynamic monitoring” capability.

Both the monitoring and memory capabilities of the DM

2®

Series

D valve are built in to the two piston-poppet stem assemblies.

During normal operation, the assemblies move between two

extreme positions. The 3rd, or intermediate, position occurs only

during valve lock-out. The valve will lock out whenever there is

sufficiently asynchronous motion between the two piston-poppet

stem assemblies. No additional external or internal devices

are needed to provide monitoring and memory. When the inlet

air supply is removed and re-applied, the valve “remembers”

whether it was in the ready-to-run or locked-out position prior

to the removal of the air supply. Resetting the valve after it has

gone in to “locked out” mode requires a momentary application

of a reset signal. Should the reset signal be inadvertently left on

(permanent signal), the valve will nevertheless go back in to lock-

out mode.

2. Description

The three way valve with DM

2®

capability consists of two main

valve systems and two pilot valve systems. The air flow paths

within the main valve systems are a proven combination of both

SERIES and PARALLEL paths.

Both pilot valves and both main valve elements are interconnected

with each other pneumatically. The main valve elements control the

air via Crossflow™ air passages from inlet (port 1) to outlet (port 2).

Air flows first through a control element on one side of the valve

to a control element on the second side of the valve, hence a

series flow path. A parallel flow path starts on the second side

of the valve and flows to the first side of the valve. A total of four

elements control air flow from inlet to outlet. Air flow from outlet

(port 2) to exhaust port (port 3) occurs in parallel via the exhaust

poppets of both main valve elements.

In normal operation, pilot air supply is maintained as long as the

two main elements operate in a synchronous manner. Whenever

there is asynchronous motion, however, one of the pilot air supplies

will be exhausted.

Sufficient pilot pressure is necessary to move the main valve

elements to their fully actuated or de-actuated positions.

Lack of sufficient pilot pressure will prevent a valve element from

fully shifting, resulting in the element stopping in the intermediate,

locked-out position.

3. Application

Uncontrolled movements of cylinders or rotary drives risks harm

to personnel and machinery. In order to reduce risk of injuries

and damage, pneumatic controls should ideally meet strict safety

requirements.

ROSS developed the DM

2®

Series D double valves for controlling

pneumatic clutch and brake mechanisms on mechanical power

presses. However, the features and functions built in to the

valve make it an ideal product to meet the specifications and

standards associated with other critical applications. Because

of its redundant design and the fact that the air is directed in a

Crossflow™ and SERPAR

®

pattern, the DM

2®

valve provides a

very high level of safety.

Application & Safety Category

Valve Response Charts

Exhausting

Filling

www.rosscontrols.com

11