Dm2 series d double valves information, Series d double valves, Installation example – Ross Controls 3_2 VALVES SERIES DM2 D User Manual

Page 3: Monitoring

The ROSS DM

2®

Series D double valves provide significant

features in response to the changing demands of the

mechanical press industry and its associated standards and

regulations regarding the control of pneumatically controlled

clutch and brake applications. The consensus requirements

of the regulations and good practices require that, in case of

a failure within the valve, the clutch and brake mechanisms be

quickly exhausted, a monitor takes action to prevent further

operation, and a method to alert personnel is incorporated.

These features also make the valve suitable for use in other

Category 3 & 4 safety-related applications.

A ROSS DM

2®

Series D double valve has two valve elements

independently controlled by two solenoid pilots. The two

valve elements share common inlet, outlet, and exhaust ports.

When the pilot valves are simultaneously energized, the valve

elements operate so that the valve functions as a 3/2 normally

closed valve.

If one of the valve elements does not open or close synchronously

with the other, the valve goes into a faulted condition, exhausts

downstream air and keeps residual outlet pressure to less than

1% of inlet supply. This is an important safety characteristic of

the ROSS DM

2®

Series D design.

Valve element redundancy provides an additional safety factor,

as the likelihood of a malfunction in both valve elements in the

same cycle is considered extremely remote.

DM

2®

valves also have an internal monitor that is integrated

into the valve elements. Should the valve operate abnormally,

the monitor will lock-out the valve and prevent further operation

until corrective action is taken.

IMPORTANT NOTE:

Standards, regulations, and good practice all require that

mechanical power presses or other hazardous machines using

a pneumatically-controlled clutch and brake mechanism be

equipped with a double valve with a self-contained monitoring

device and/or an external monitoring system, which inhibits

further operation of the valve and machine in the event of a

failure within the valve. Of course, a double valve is just one

of the components in a press control system, and all other

elements of the system should be planned with safety as a

primary consideration.

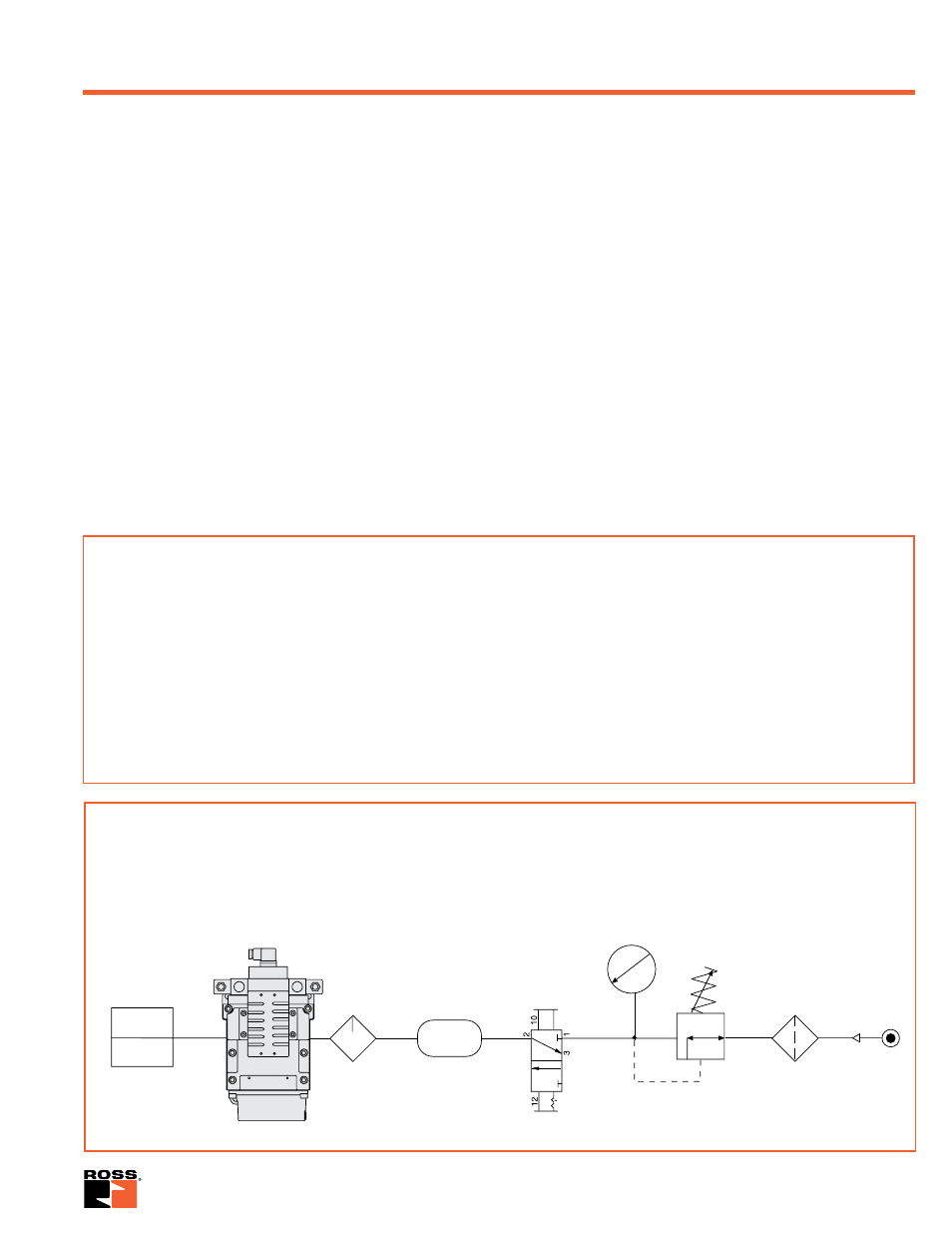

DM

2®

Series D Double Valves

Installation Example

Pressure regulator

Clutch and brake

combination

Filter and

water separator

Pressure gauge

Volume

DM

2®

Series D Double Valve

(Status indicator – optional)

Lubricator

L-O-X

®

- Valve

DM

2®

Monitoring:

The DM

2®

is a patented 3/2 normally closed valve (with an

intermediate, lockout position) distinguished by Crossflow

TM

passages with poppet and spool valving on the main valve

stems. This arrangement provides the valve’s outstanding

flow characteristics and an integrated monitoring capability

with total memory. The valve provides dynamic monitoring

and dynamic memory.

Dynamic Monitoring means that all monitoring components

change state on every valve cycle. Should the valve elements

cycle asynchronously, the valve will exhaust downstream air

and lock-out, prohibiting further operation.

Dynamic Memory within a monitoring system indicates that

when a valve lock-out occurs, the valve will retain the fault

information regardless of air or electrical changes. The DM

2®

system can only be reset by a defined operation/procedure, and

will not self-reset (turning the valve off and on) or reset when

inlet air supply is removed and re-applied. Such automatic

resetting would conceal potential hazards from the operator.

www.rosscontrols.com

3