Manual striping hook-up, Automatic striping hook-up – Paasche Airbrush A-US User Manual

Page 4

Page 4

Paasche UTS, UPS-1 and A-US Manual and Automatic Stripers

No.

Part No.

Description

A.

27SC 3 OUNCE GRAVITY CUP ASSEMBLY:

1. UB-255

Cover

2. 4-G

Gasket

3. 27SCC

3 Ounce Cup

B. USG SWIVEL STRIPING GUIDE:

1. U-509

Spring Washer

2. UB-506

Guide Support

3. U-507

Guide

4. UH-298

Screw

5. UH-297A

Body

C. U-508 LOCKNUT—To be used with:

1.

SNH

Special—Needle Type Nib †

2.

SNM-2

Special—Line Striper Nib †

3.

SNF-

Select From Sizes:

3/8-1/2-5/8-3/4-7/8

D. U-373 LOCKNUT—To be used with:

1.

SNF-

Select From Sizes:

1/32 up to 5/16 Call

Factory for Available Sizes.

2.

SNR-

Select From Sizes:

-1/64-1/32-1/16-3/32-1/8

-3/16-1/4

† C1 and C2—Specially Made Nibs.

Prices furnished upon request.

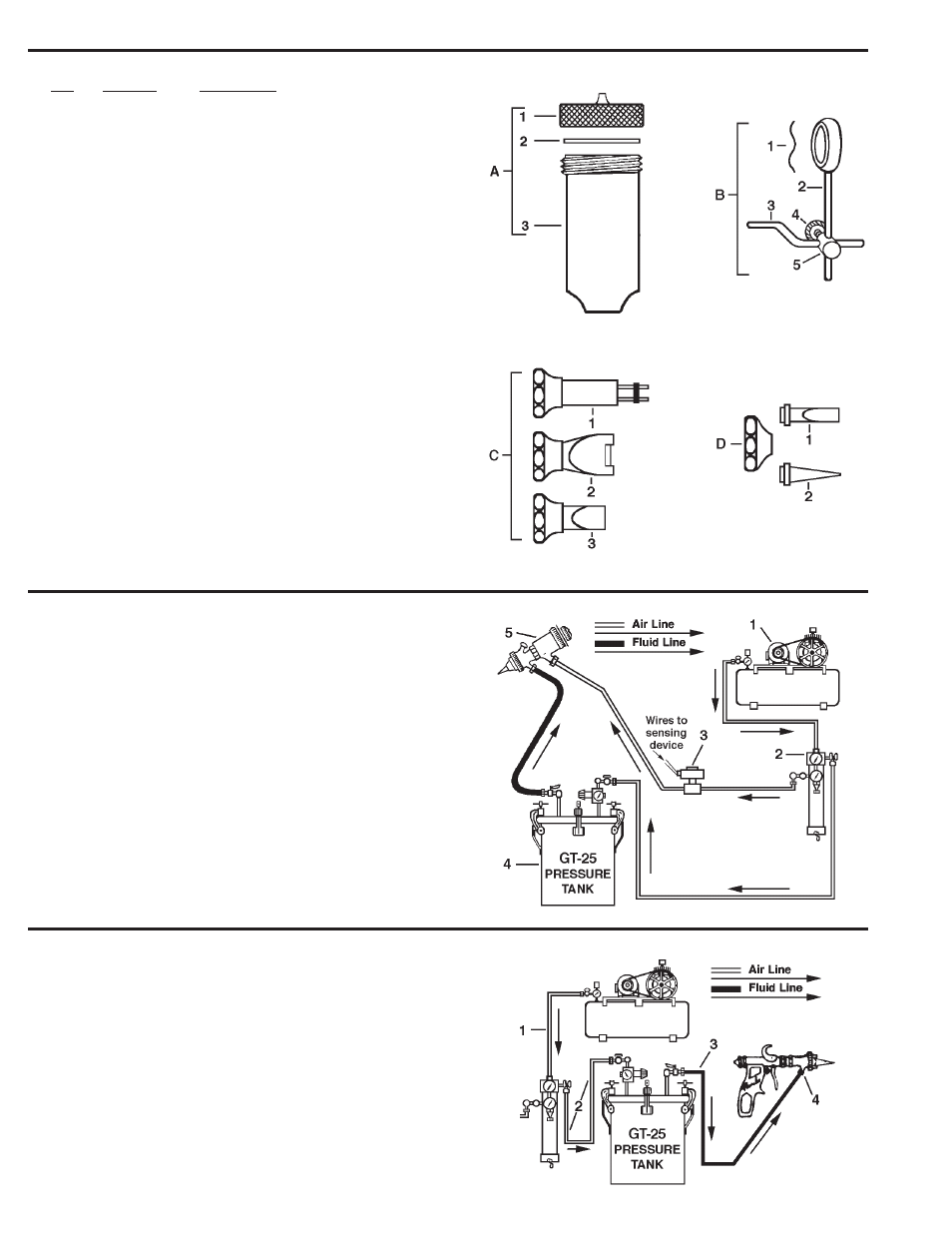

Manual Striping Hook-Up

INSTRUCTIONS:

Make sure all Air and Fluid hoses are blown out to insure clean

air and fluid.

1. Attach Air line supply to Air Inlet on Moisture Condenser.

2. Attach Air Hose to Valve on line pressure Gauge and to

Tank Air Inlet Valve.

3. Attach Fluid Hose to Fluid Outlet Valve on Tank and to

Fluid Inlet Connection #4 on Manual Striping Gun.

Automatic Striping Hook-Up

INSTRUCTIONS:

Blow out all the hoses to remove foreign particles. Make Air and

Fluid connections as shown Tighten fittings securely. Strain

material before placing in tank.

1. Air Compressor must have sufficient capacity for

application.

2. Air Regulator; adjust pressure required to operate Striping

Gun, not to exceed 45 P.S.I. air and fluid pressure.

3. Explosion-proof Solenoid Valve with air dump feature,

mount as close to Gun as possible for fast on-off action.

4. Pressure Tank; adjust Regulator on Tank Unit to minimum

pressure required to deliver fluid to Striping Gun #5.