Installation, A-17 – Lincoln Electric IM10144 POWER WAVE S700 User Manual

Page 24

If Sense Leads ARE NOT Used:

• Avoid common current paths. Current from adja-

cent arcs can induce voltage into each others cur-

rent paths that can be misinterpreted by the power

sources and result in arc interference.

If Sense Leads ARE Used:

• Position the sense leads out of the path of the weld

current. Especially any current paths common to

adjacent arcs. Current from adjacent arcs can

induce voltage into each others current paths that

can be misinterpreted by the power sources, and

result in arc interference.

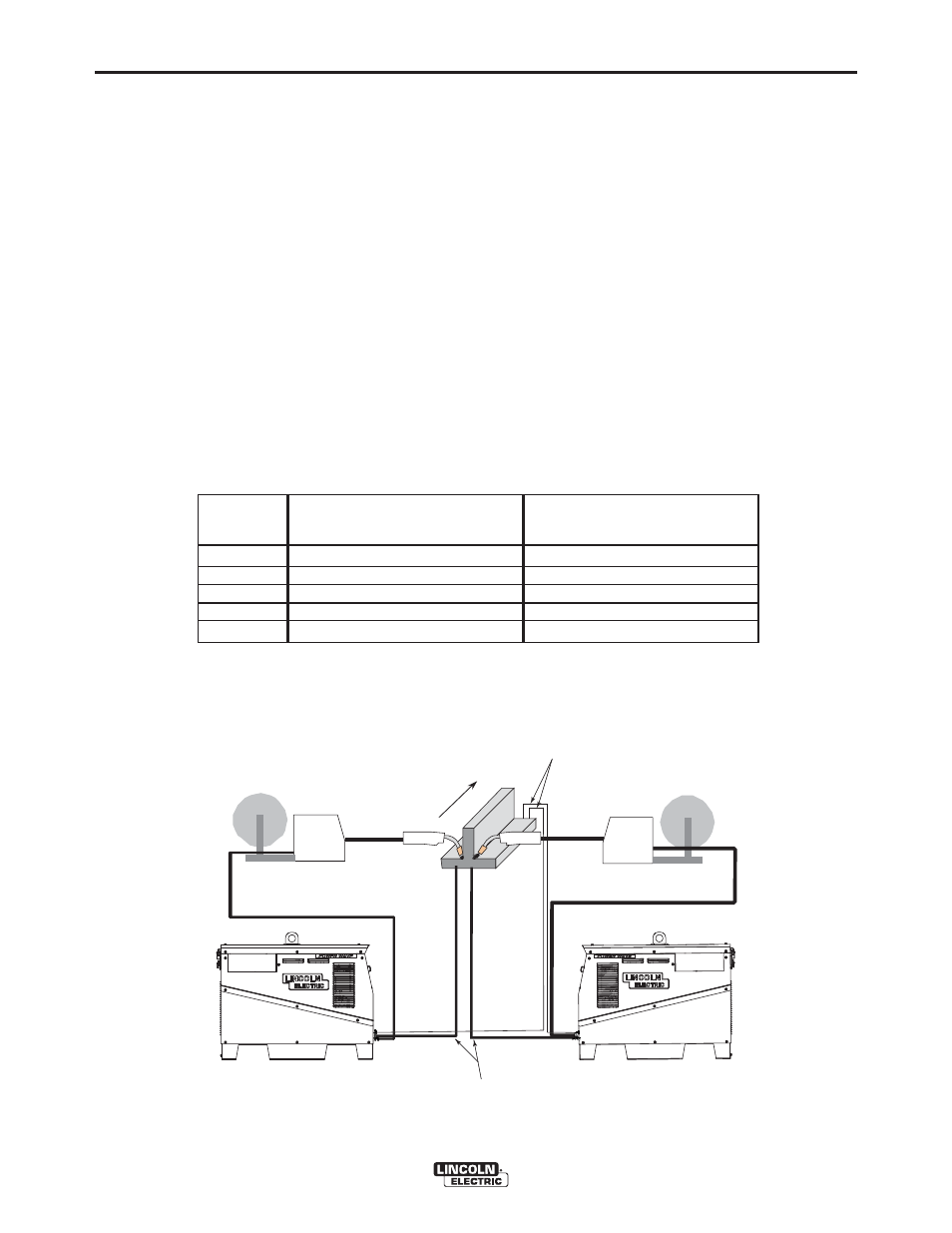

• For longitudinal applications, connect all work leads

at one end of the weldment, and all of the work volt-

age sense leads at the opposite end of the weld-

ment. Perform welding in the direction away from

the work leads and toward the sense leads.

(See Figure A.11)

DIRECTION

OF TRAVEL

CONNECT ALL

WORK LEADS AT

THE BEGINNING

OF THE WELD.

CONNECT ALL SENSE

LEADS AT THE END

OF THE WELD.

FIGURE A.11

A-17

INSTALLATION

POWER WAVE

®

S700

A-17

General Guidelines for Voltage Sense Leads

Sense leads should be attached as close to the weld

as practical, and out of the weld current path when

possible. In extremely sensitive applications it may be

necessary to route cables that contain the sense

leads away from the electrode and work welding

cables.

Voltage sense leads requirements are based on the

weld process (See Table A.2)

VOLTAGE SENSING CONSIDERATIONS

FOR MULTIPLE ARC SYSTEMS

Special care must be taken when more than one arc

is welding simultaneously on a single part. Multiple arc

applications do not necessarily dictate the use of

remote work voltage sense leads, but they are strong-

ly recommended.

Process

GMAW

GMAW-P

FCAW

GTAW

SMAW

Electrode Voltage Sensing

(1)

67 lead

67 lead required

67 lead required

67 lead required

Voltage sense at studs

Voltage sense at studs

Work Voltage Sensing

(2)

21 lead

21 lead optional

(3)

21 lead optional

(3)

21 lead optional

(3)

Voltage sense at studs

Voltage sense at studs

TABLE A.2

(1)

The electrode voltage sense lead (67) is automatically enabled by the weld process, and integral to the 5 pin arclink control cable (K1543-

xx).

(2)

When a work voltage sense lead (21) is connected the power source will automatically switch over to using this feedback (if the auto

sense feature is enabled).

(3)

Negative polarity semi-automatic process operation WITHOUT use of a remote work sense lead (21) requires the Negative Electrode

Polarity attribute to be set.