Installation, Input connection, Input fuse and supply wire considerations – Lincoln Electric IM10144 POWER WAVE S700 User Manual

Page 11: Input voltage selection, Warning

A-4

INSTALLATION

POWER WAVE

®

S700

A-4

INPUT CONNECTION

ELECTRIC SHOCK can kill.

Only a qualified electrician should

connect the input leads to the

Power Wave

®

S700. Connections

should be made in accordance with all local and

national electrical codes and the connection dia-

grams located on the inside of the

reconnect/input access door of the machine.

Failure to do so may result in bodily injury or

death.

------------------------------------------------------------------------

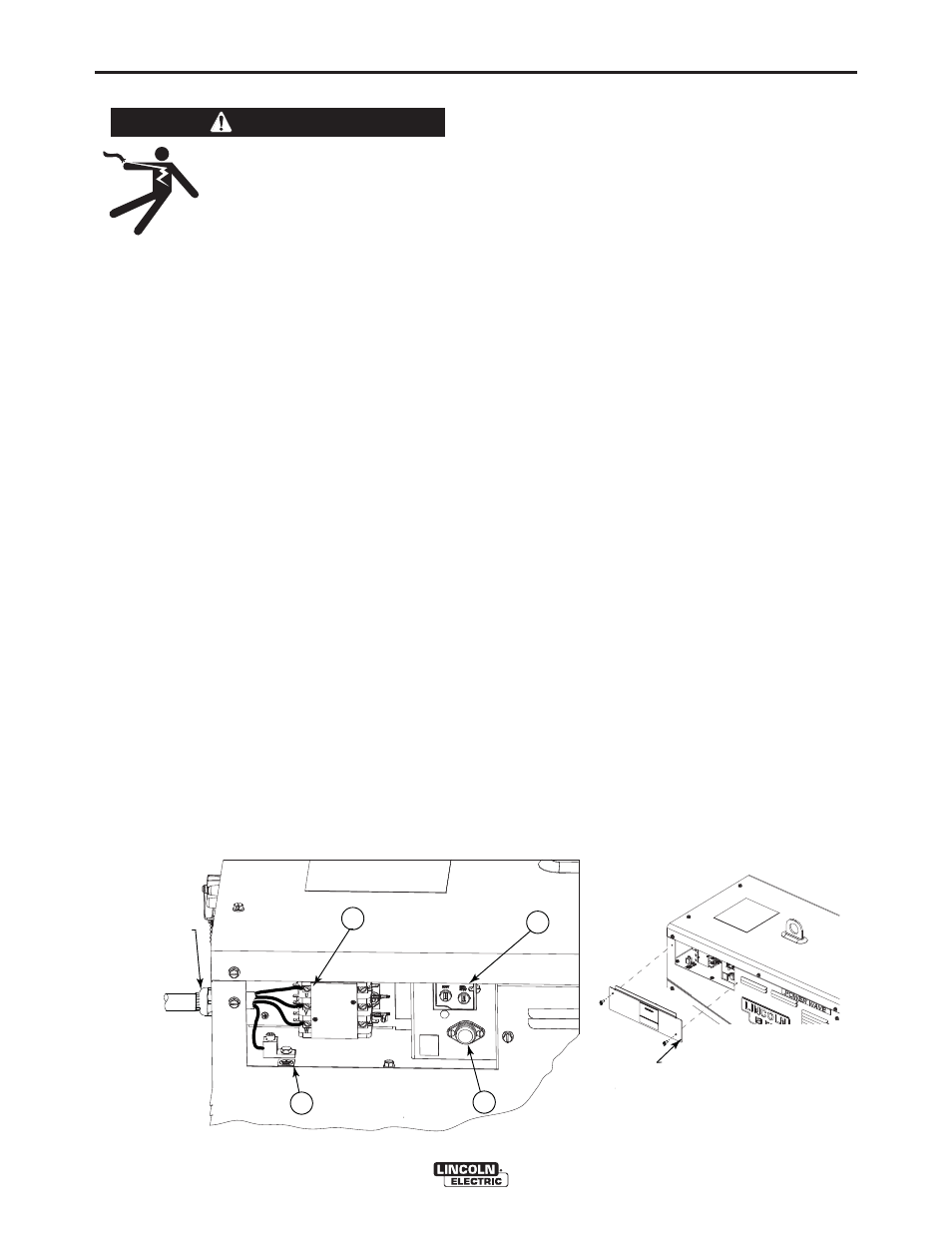

(See Figure A.1)

Use a three-phrase supply line. A 1.75 inch diameter

access hole with strain relief is located on the case

back. Route input power cable through this hole and

connect L1, L2, L3 and ground per connection dia-

grams and National Electric Code. To access the

input power connection block, remove two screws

holding the access door to the side of the machine.

ALWAYS CONNECT THE POWER WAVE GROUND-

ING LUG (LOCATED AS SHOWN IN FIGURE A.1)

TO A PROPER SAFETY (EARTH) GROUND.

Input Power Compartment Controls Description:

1. Input Contactor: Connects 3-phase power to the

welder.

2. Ground Lug: Provides an “Earth Ground” connec-

tion to the welder frame.

3. Auxiliary Reconnect: Allows for easy tap selection

on the auxiliary transformers over the range of input

voltages.

4. Fuse: Protects the auxiliary transformers.

INPUT FUSE AND SUPPLY WIRE

CONSIDERATIONS

Refer to Specification Section for recommended fuse,

wire sizes and type of the copper wires. Fuse the

input circuit with the recommended super lag fuse or

delay type breakers (also called "inverse time" or

"thermal/magnetic" circuit breakers). Choose input

and grounding wire size according to local or national

electrical codes. Using input wire sizes, fuses or cir-

cuit breakers smaller than recommended may result in

"nuisance" shut-offs from welder inrush currents, even

if the machine is not being used at high currents.

INPUT VOLTAGE SELECTION

Welders are shipped connected for the highest input

voltage listed on the rating plate. To move this con-

nection to a different input voltage, see the diagram

located on the inside of the input access door, also

illustrated below. If the Auxiliary lead (indicated as ʻAʼ)

is placed in the wrong position, there are two possible

results. If the lead is placed in a position higher than

the applied line voltage, the welder may not come on

at all. If the Auxiliary lead is placed in a position lower

than the applied line voltage, the welder will not come

on, and the two circuit breakers in the reconnect area

will open. If this occurs, turn off the input voltage,

properly connect the auxiliary lead, reset the breakers,

and try again

WARNING

POWER CONNECTION BLOCK

INPUT CORD STRAIN RELIEF

CONNECT EACH PHASE OF A THREE-PHASE

CONDUCTOR HERE

GROUND CONNECTION

CONNECT GROUND LEAD PER LOCAL

AND NATIONAL ELECTRIC CODE

ROUTE INPUT CORD

THROUGH RELIEF AND

TWIST NUT TO TIGHTEN

INPUT POWER

ACCESS DOOR

1

3

4

2

FIGURE A.1