Caution – Lincoln Electric IM10163 FLEX FEED 74 HT User Manual

Page 53

E-3

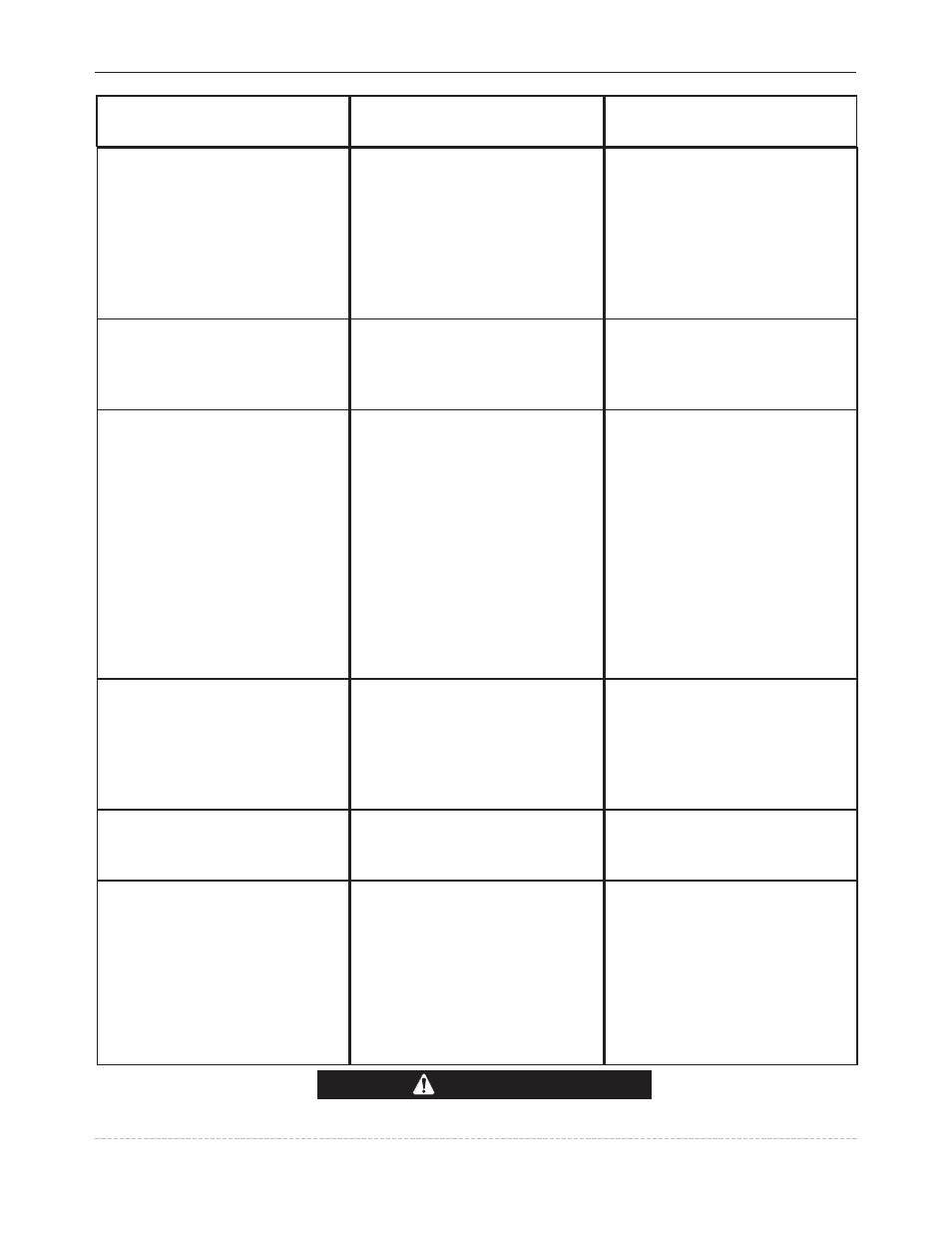

TROUBLE SHOOTING

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

Wire feed speed consistently oper-

ates at the wrong value. The speed

changes when the wire feed speed

knob is adjusted.

The wire feed speed stuck at 200-

300 in/min and there is no change

when the wire feed speed knob is

adjusted.

Variable or "hunting" arc.

The wire drive feeds wire at the cor-

rect speed but there is not welding

output.

There is gas flow but the feeder

does not feed wire

Poor arc starts with sticking or

"blast-offs", weld porosity, narrow

and ropy looking bead.

1. The jumper lead 20 tooth/30 tooth

pinion gear is connected improp-

erly.

2. The wrong gear is installed in the

wire drive.

3. The wrong decal was placed on

the case front.

4. The brushes on the motor are

worn.

1. The tachometer is connected

improperly.

2. The tachometer has failed.

1. Wrong size, worn and/or melted

contact tip

2. Worn work cable or poor work

connection.

3. Wrong polarity.

4. The gas nozzle is extended

beyond the contact tip or the wire

stickout is too long.

5. Poor gas shielding on processes

requiring gas.

1. If a gouging kit is installed, the

gouging switch is in the “gouge”

position

2. If a gouging kit in installed, verify

there is continuity from the elec-

trode input to the wire drive.

1. If the advanced user interface is

installed, verify the preflow time

has not been set to a high value

1. Improper procedures or tech-

niques.

1. Properly connect the jumper lead

in the harness..

2. Install the proper pinion gear in

the wire drive.

3. Place the correct WFS decal on

the case front.

4. Inspect and replace the motor

brushes.

1. Verify all of the tachometer leads

are properly connected.

2. Replace the motor and tachome-

ter assembly.

1. Replace the contact tip.

2. Verify all work and electrode con-

nections are tight and that the

cables are in good condition.

Clean/replace as necessary.

3. Adjust the polarity to match the

process.

4. Adjust the gas nozzle and shorten

the stickout to ½ to ¾ inches.

5. Check gas flow and mixture.

Remove or block sources of

drafts.

1. Place the rocker switch in the

welding position.

2.

Repair loose connections.

Replace the contactor.

1. Adjust the preflow timer for a

shorter amount of time.

1. See "Gas Metal Arc Welding

Guide" (GS-100)

FLEX FEED™ 74 HT