Warning – Lincoln Electric IM10163 FLEX FEED 74 HT User Manual

Page 10

A-3

INSTALLATION

FLEX FEED™ 74 HT

SAFETY PRECAUTIONS

ELECTRIC SHOCK CAN KILL.

• ONLY QUALIFIED PERSONNEL

SHOULD PERFORM THIS

INSTALLATION.

• Turn the input power OFF at the

disconnect switch or fuse box

before attempting to connect or

disconnect input power lines,

output cables or control cables.

• Do not touch the wire drive, drive rolls, wire

coil or electrode when welding output is ON.

• Wire feeder may be connected to a piece of

automatic equipment that may be remotely

controlled.

• Do not operate with covers, panels or guards

removed.

• Do not let the electrode or wire spool touch the

wire feeder housing.

• Insulate yourself from the work and ground.

• Always wear dry insulating gloves.

• The lift bail is insulated from the wire feeder

enclosure. If an alternate hanging device is

use. it must be insulated from the wire feeder

enclosure.

MOVING PARTS can injure.

• Keep away from moving parts.

-------------------------------------------------------------------

WARNING

LOCATION

The Flex Feed 74 HT is rated IP2X and is suitable

for indoor use.

For best wire feeding performance, place the Flex

Feed 74 HT on a stable and dry surface.

When suspending the wire feeder, insulate the

hanging device from the wire feeder enclosure.

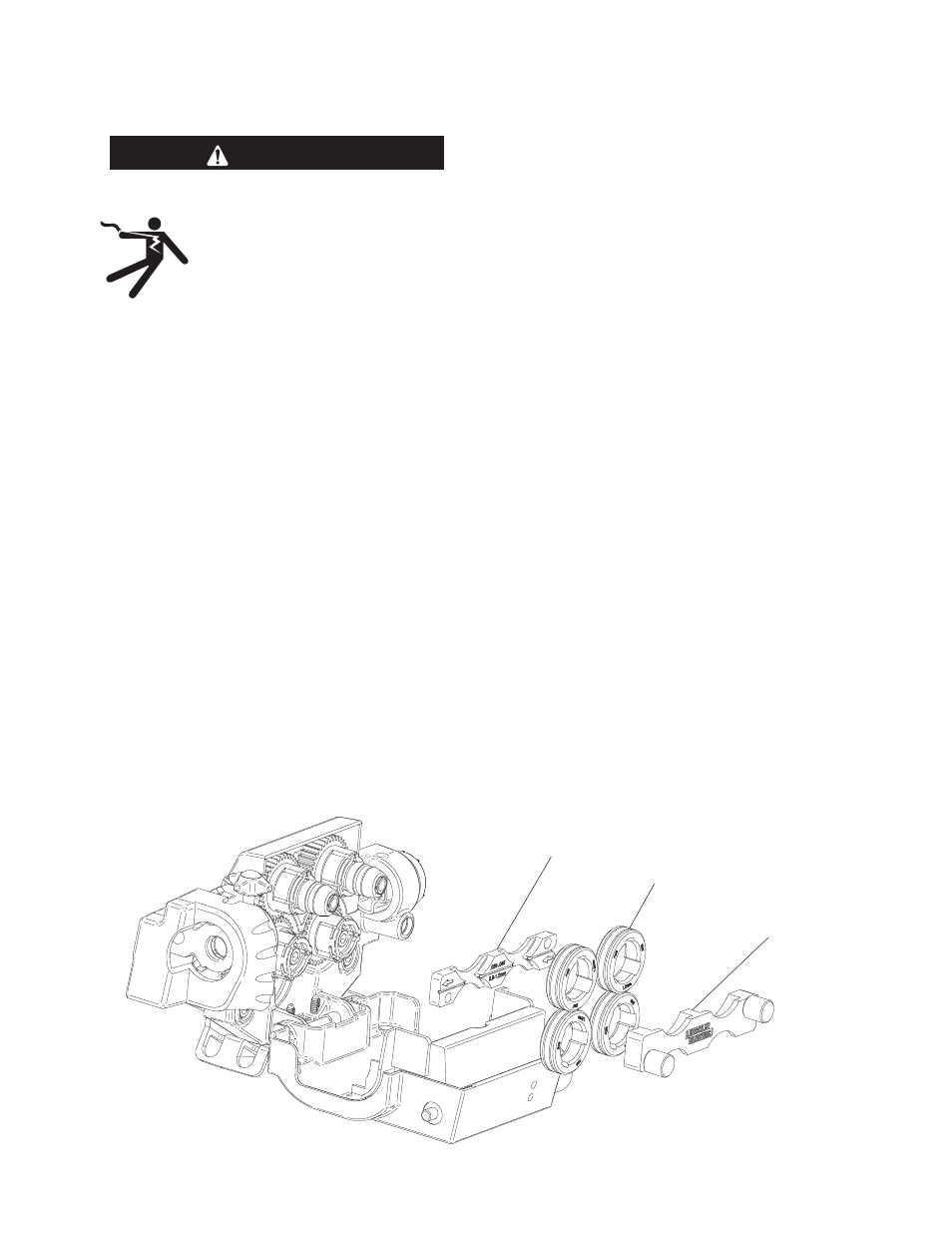

DRIVE ROLL AND WIRE GUIDES

(See Figure A.1)

1. Turn power OFF at the welding power source.

2. Open the wire drive door by pulling on the top.

3. Remove the outer wire guide.

4. Remove drive rolls by pulling straight out. It may be

necessary to wiggle the drive roll to free it from the

snap ring.

5. Remove the inner wire guide.

6. Install the new inner wire guide, with the arrow

pointing in the direction of wire travel.

7. Install the drive rolls and outer wire guide.

8. Close the wire drive door and adjust the pressure

setting accordingly.

INNER WIRE DRIVE

DIVE ROLLS

OUTER WIRE DRIVE

FIGURE A.1