Wiring hookup, System example – Warner Electric FM Series Foot Mounted Load Cells User Manual

Page 4

4

Warner Electric • 800-825-9050

P-2012-1

Wiring Hookup:

The load cell requires a +15VDC and a -15VDC

power supply. The 5V/15V switch inside the

MCS2000-CTLC must set to +/-15VDC.

Terminate all unused wires from cable.

Wiring example using One Load Cell with the

MCS2000-CTLC control

Red (+15V)

White (Ground)

Yellow (Signal)

BLUE (-15V)

+UCELL/SEN+

CELL1+/SENS IN

CELL1-

-UCELL/SENS

Ground (OV)

Shield

+UCELL

CELL2+

CELL2-

-UCELL

SHIELD

FM Series Load Cell

MCS2000-CTLC

No Connection

No Connection

No Connection

No Connection

Add Jumper

Red (+15V)

White (Ground)

Yellow (Signal)

Blue (-15V)

+UCELL/SEN+

CELL1+/SENS IN

CELL1-

-UCELL/SENS

Ground (OV)

Shield

+UCELL

CELL2+

CELL2-

-UCELL

Ground (OV)

Shield

Red (+15V)

White (Ground)

Yellow (Signal)

Blue (-15V)

N/C

N/C

FM Series Load Cell

FM Series Load Cell

MCS2000-CTLC

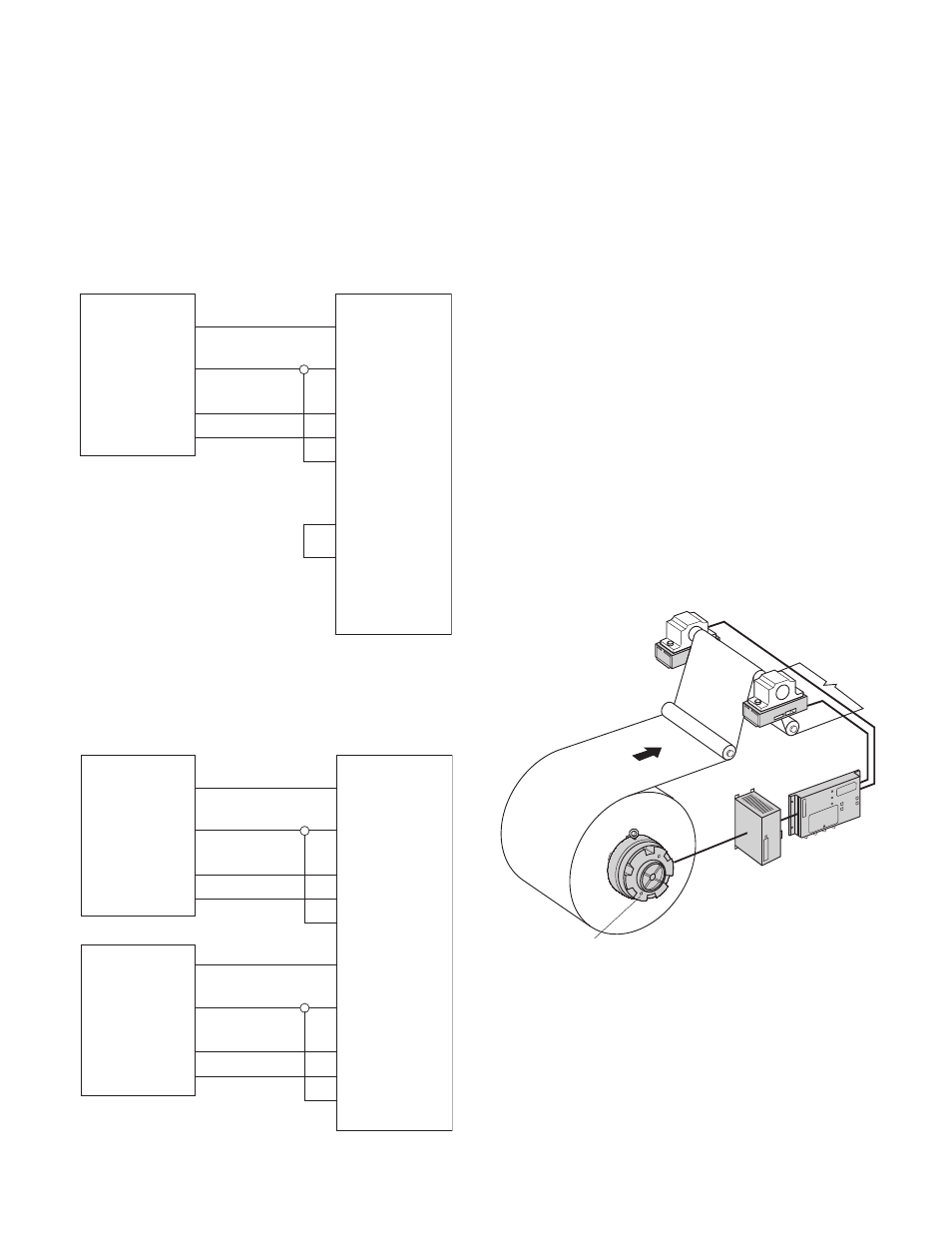

Figure 2

Figure 3

Wiring example using 2 load cells with the

MCS2000-CTLC control

Notes:

It is recommended to use the load cell

in a compression application. It must be fitted

on a flat surface in order to avoid original

sensitive plate stress. Do not load the sensor

before mounting it with screws on the

mounting surface.

System Example:

FM Load Cell with an Electric Brake

This is a typical load cell unwind application

example. The electric brake varies the tension

on the web depending on the feedback from the

load cell. The load cell signal is amplified and

interpreted in the controller (MCS2000-CTLC).

The controller then puts out a corresponding

0-10 VDC signal to the power supply and drive

(MCS2000-PSDRV). The PSDRV then amplifies

and interprets the signal from the controller and

puts out a corresponding 0-24 VDC signal to the

brake to apply either more or less braking.

Figure 4

Magnetic Particle Brake

MCS2000-PSDRV

Power Supply

and Drive

MCS2000-

CTLC

FM Load

Cell

FM Load

Cell