Warner Electric MCS-500 Series LED Photoelectric Control User Manual

Page 3

3

Warner Electric • 800-825-9050

819-0504

Specifications (Continued)

Optional Outputs:

MCS-850 Relay, SPDT 5 A.

MCS-851 Open collector,

30 VDC @ 20 ma.

Cycle rate:

3000 cycles per minute,

max.

Installation

Mounting

1. Mount the base securely on a firm support

using the two screws provided with the thread-

ed #8-32 holes in the unit’s base. See mount-

ing dimensions. Figure 4.

For ease of mounting and aligning use the

optional mounting bracket, part number 7150-

101-020.

2. For best results, mount the scanner vertically

to decrease the possibility of dirt and other for-

eign matter from blocking the beam.

Alignment

1. The unit is shipped set for light operation. The

output device will activate when light from the

source is reflected back to the receiver. for

dark operation, refer to the light/dark switch

label enclosed with the unit, or see Figure 3.

2. Loosen the screw on the top cover so that the

clear dome will swivel freely, exposing the

adjustments. Set the sensitivity adjustment to

maximum by turning the potentiometer fully

clockwise as shown in Figure 4 and connect

the 120 VAC leads to the proper terminals.

(Caution: Use wire with insulation suitable for

120 VAC.) Plug one of the output modules list-

ed under the module options into the base.

The visible LED indicator on top of the scanner

will light when the infrared beam is completed

from the source to the sensor.

3. Place the target in the position detection is

desired. With the scanner aimed at the target

and mounted loosely on its mounting bracket,

swivel the scanner up and down and left and

right, noting the position in which the visible

alignment indicator is lit. Position the scanner

in the center of this area and secure the scan-

ner mounting. Note that the area surrounding

the target must be nonreflective or satisfactory

operation will not be obtained. Also, any reflec-

tive objects in the scanner’s optical path and

operational range will be sensed. Care should

be taken to ensure that only the desired target

is capable of being sensed by the scanner.

The sensitivity adjustment may be used to

decrease the sensitivity of the scanner for opti-

mum operation.

Note: In order to achieve optimum performance

when replacing the electronic head, some

realignment may be necessary.

Modules And output Wiring

1. Connect the output wires to the proper termi-

nals. See Typical Terminal Wiring, Figure 2.

2. Insert output module in the base.

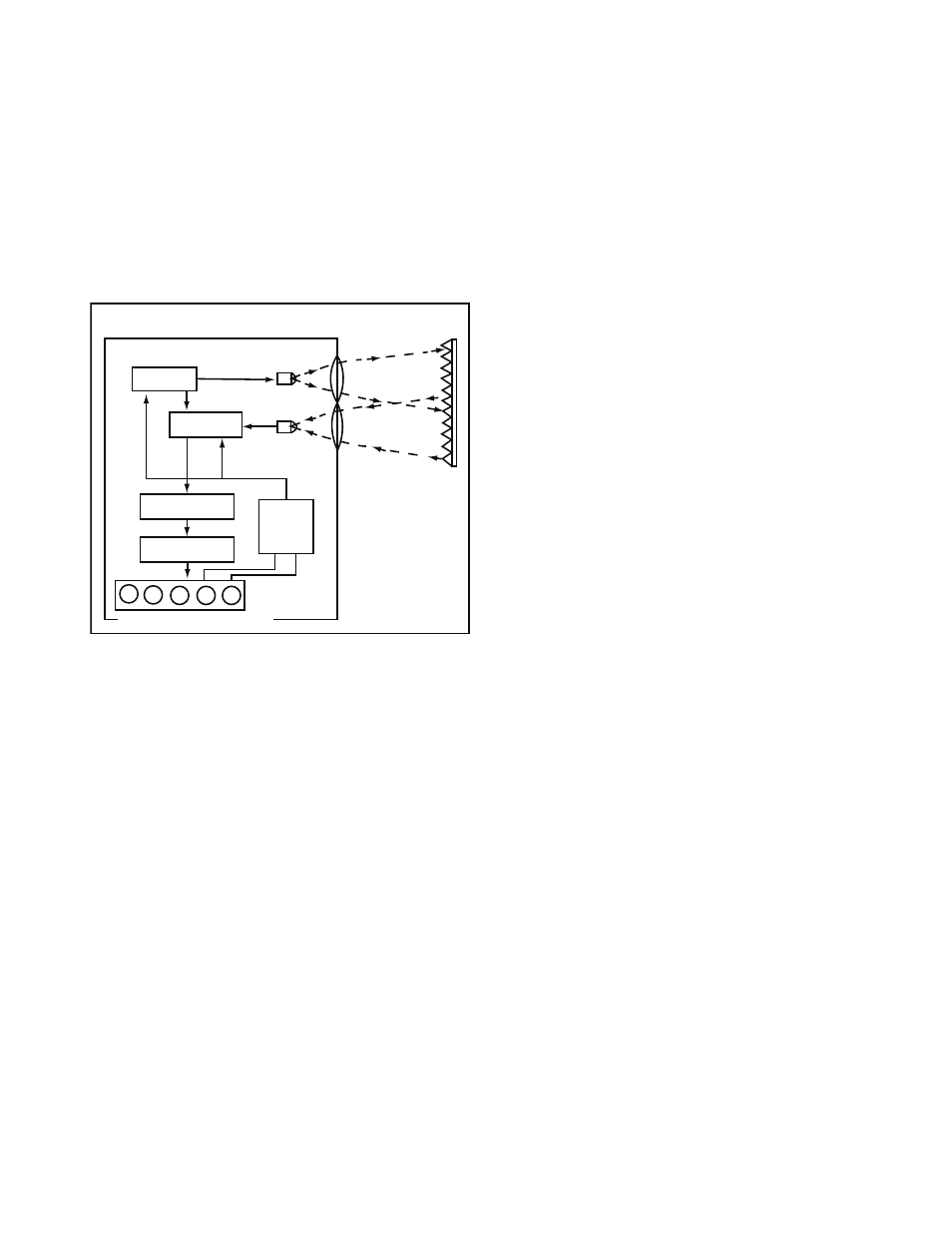

BLOCK DIAGRAM

SCANNER

LED

OSC.

AMPLIFIER

RETROREFLECTOR

POWER

SUPPLY

TIMER

OUTPUT MODULE

N/C N/O C INPUT VOLT

AGE

PHOTO-

TRANSISTOR

Figure 1