Install brakes, Install armature in drum – Warner Electric Wheel-Brakes (Std) User Manual

Page 8

Figure 2-8

Location of Shims for Welding Flange

With an electric arc, tack both outer edges of hacksaw

cut, if cut is present. Tack flange (Figure 2-9) to axle in

approximately four places. Complete weld by welding

hacksaw cut first - outer edge to axle - then make

continuous weld between flange and axle. Remove

bolts that hold flange to welding fixture and remove

hub, drum, and welding fixture from axle. Complete

weld on opposite side of flange. Remove welding

fixture from drum and clean all weld splatter from drum

or spindle surfaces.

NOTE:

Do not use same hub and drum assembly as

template for all wheels. Use hub and drum

designated for each wheel location.

Install Brakes

The desired position for mounting brakes on the axle is

indicated in Figure 2-10. Whenever possible they

should be mounted so that the brake spider anchor is

down and 45° to the rear as determined by forward

vehicle travel. Mounting brakes in this position affords

the best wheel bearing loading during application of

brakes. If the brakes are marked right and left hand

because of the type and location of lining segments in

brake shoes, the woven lining (with arrow indicating

drum rotation for forward vehicle travel) must always

be on the toe end of the shoe ring. Left and right hand

are determined by facing in the direction of forward

vehicle travel. In the event it is not possible to locate

the brake spider anchor as shown, the anchors must

be in the same relative location for all wheels.

Figure 2-10

Brake Mounted in Correct Position

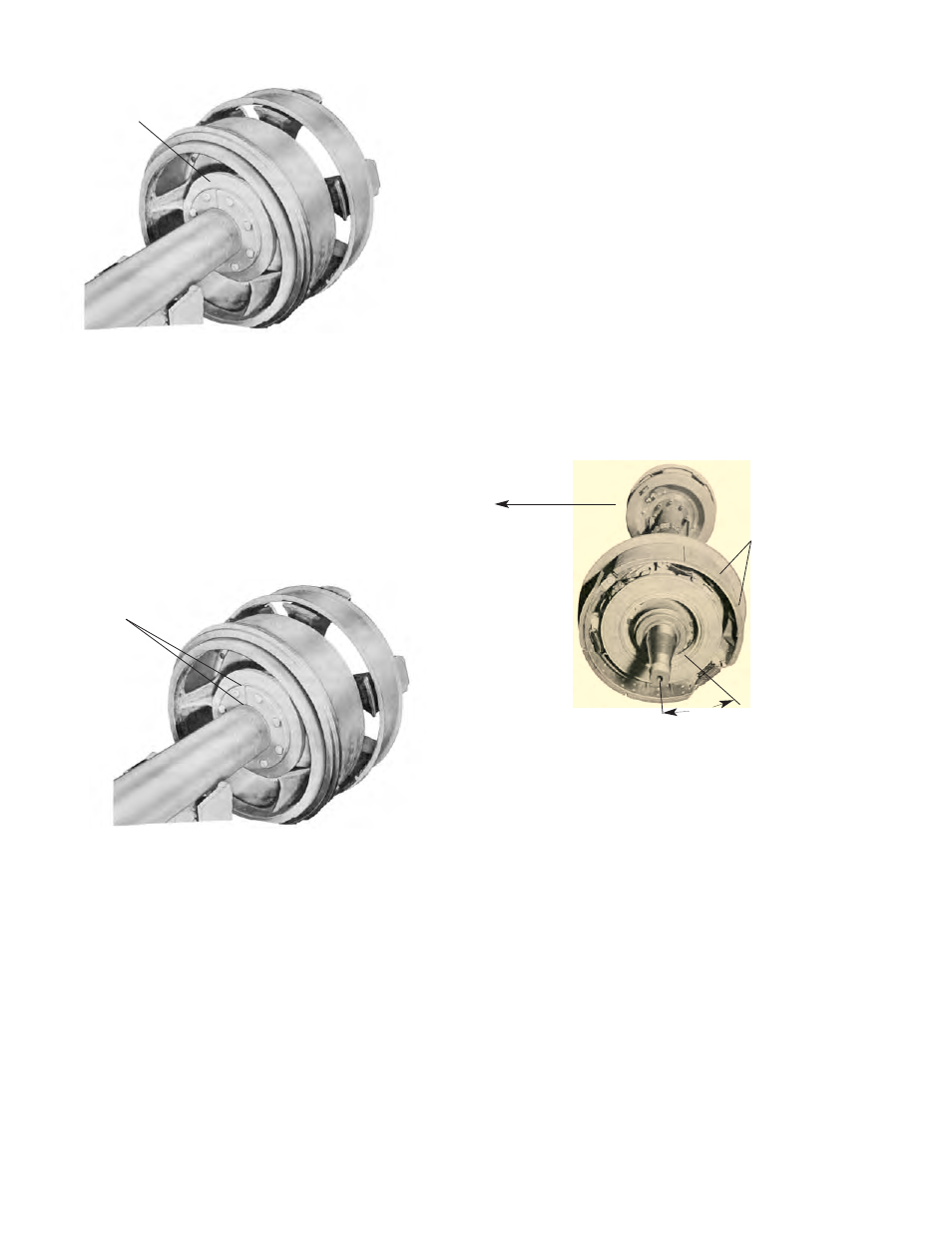

Install Armature in Drum

Bolt armature inside of drum (Figure 2-11). Armature

bolts directly to armature adapter for 16-

1

⁄

2

” series

brakes. On 12-

1

⁄

4

x 5-

1

⁄

2

” and 15 x 3” brakes, grease

guard is placed between armature and drum when

armature is bolted in place. A thin coating of

“Permatex” or other suitable sealer must be used

between grease guard and drum at this time.

8

Warner Electric • 800-825-9050

819-0514

Figure 2-9

Weld Points on Flange

Shims

Tack Weld

Direction

of Travel

For Brakes

Marked Right

and Left Hand

Locate Woven

Lining on

Toe End

Brake

Spider

Anchor

45°