Warner Electric Wheel-Brakes (Std) User Manual

Page 15

15

Warner Electric • 800-825-9050

819-0514

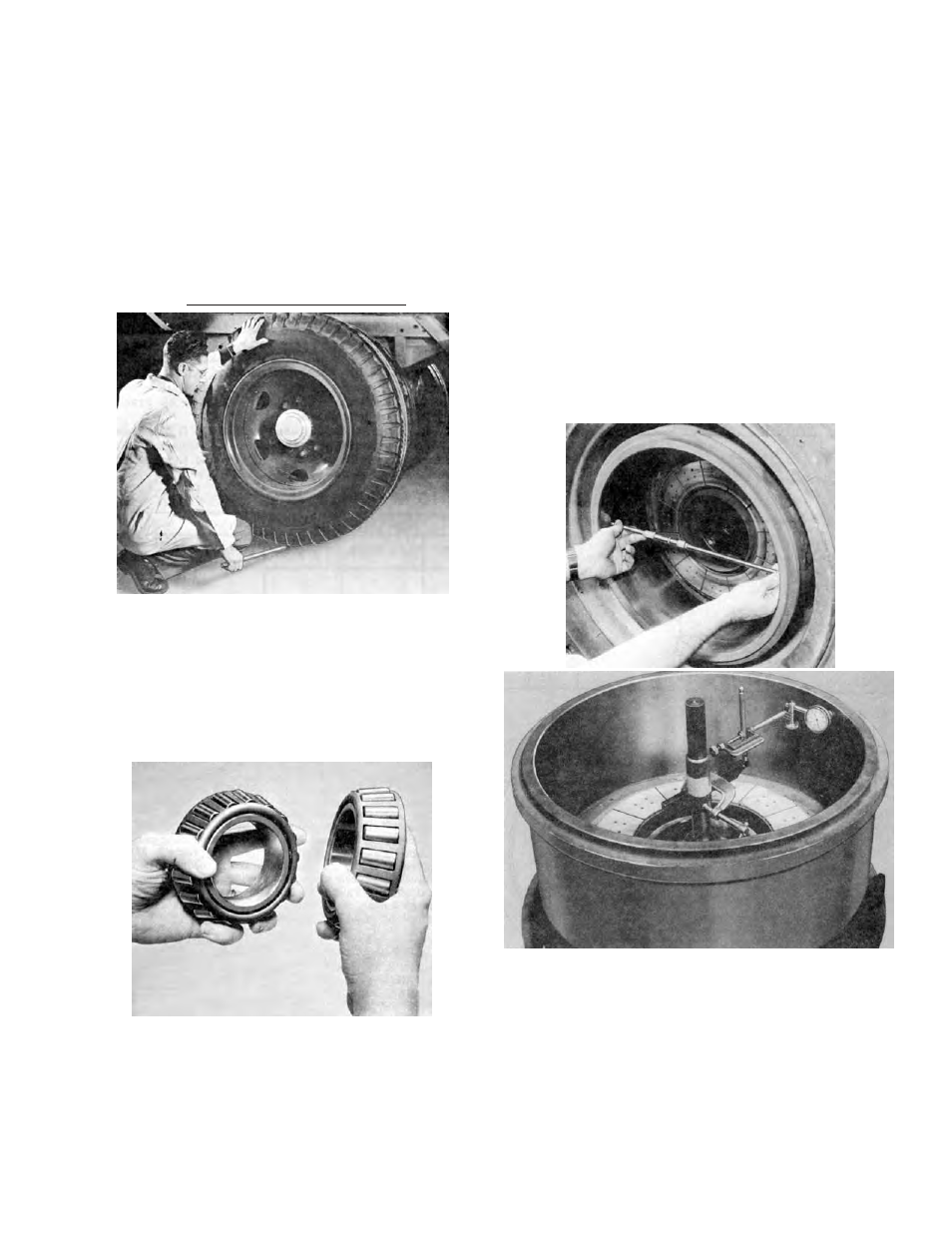

Check For Loose Wheel Bearings

During brake inspection periods and before removing

wheels, jack up each wheel and check for loose wheel

bearings (Figure 3-6). If by using a bar under the tires,

the wheels can be moved up and down on the axle the

wheel bearings are loose or worn. This condition can

cause grabby or noisy brakes, a dragging brake which

creates undue heat and rapid lining wear, or a possible

wheel lockup. Bearings Must Be Kept Snug.

Figure 3-6

Checking for Loose Wheel Bearings

When wheels must be removed for maintenance or

repair, always check for worn or defective bearings and

cups (Figure 3-7). Defective parts must be replaced.

Also check the hub for cracks and for proper fit of the

bearing cups in the hub.

Figure 3-7

Inspecting Wheel Bearings

Inspect Drums

Before relining brakes or during regular maintenance

periods, the drum should be checked for an

out-of-round condition. This may be accomplished

by an inside micrometer or a dial indicator mounted

on a stub spindle (Figure 3-8). Drums should not be

out-of-round more than .010”, since such a condition

can cause erratic, grabby brakes and possible difficulty

in assembling the wheel onto the axle.

Whenever a wheel is removed, always check the drum

mounting bolts. They must be kept tight, since a loose

drum has the same effect as loose wheel bearings. A

loose drum may also cause the drum mounting bolts to

shear off during a brake application.

Figure 3-8

Checking Drum with Inside Micrometer

and Dial Indicator