Warner Electric P 130 VAR00_VAR02 User Manual

Page 4

4 Warner Electric Europe • +33 (0)2 41 21 24 24

P-2081-WE • 2/13

4.2

Spare Parts

All orders for spare parts must state the size

of the unit with its code number, the reference

number of the part (see appendice 1), and the

quantity of each component wanted.

4.3

Dismantling / Reassembling

During maintenance work, ensure that the

mechanism to be driven by the clutch is at

rest and that there is no risk of it being started

accidentally. Also ensure that the compressed

air is turned off.

Dismantling:

• Remove the fixing screws from the cylinder

(401) or closing flange (408)

• Remove the cylinder (401) or closing flange

(408)

• Take out the piston (402)

• Remove the worn disc set

• Fit a new disc set

Start with an outer disc (302 or 305), then an

inner disc (308), and then alternate, ending of

necessity with an outer disc.

• Change the seals (701, 702)

• Refit the piston (402)

• Refit the cylinder (401) or closing flange (408)

Take care not to damage the seals while

reassembling

• Replace the cylinder (401) or closing flange

(408 fixing screws, tighten them to the torque

shown in table 3, below and secure them with

Loctite 243 or an equivalent type of product

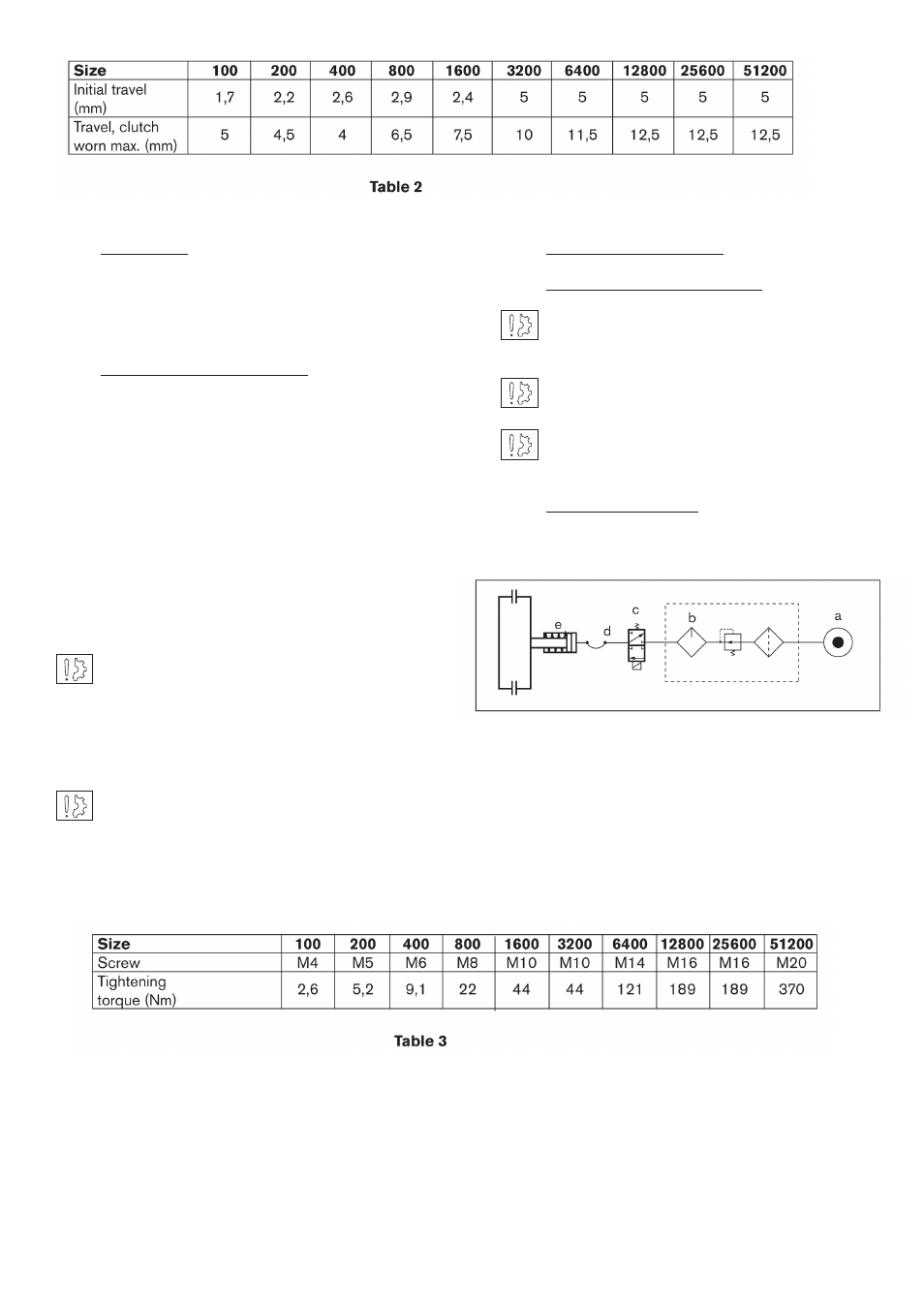

5

Pneumatic Connections

5.1

Important Recommendations

Ensure that working pressures are complied

with, to get the nominal performance from the

equipment.

Do not exceed the maximum pressures

(see table 1).

These clutches should be supplied with filtered,

oiled air.

5.1

Connection Diagram

The diagrams are only given as an indication.

Fig 1: Basic circuit for circuit under pressure

a: source of pressure

b: air treatment unit

c: distributor

d: flexi pipe and rotating seal

e: clutch engagement by application of pressure