Warner Electric E320 User Manual

Page 3

Warner Electric Europe • +33 (0)2 41 21 24 24

P-2035-WE • 2/13 3

2.2

Precautions in use and safety measures

During maintenance, ensure that the machine’s

moving parts are stationary and that there is no

risk of accidental start-up. All intervention have to be

made by qualified personnel, owning this manual.

3 Installation

3.1

Transport / storage

Our clutches and brakes are supplied in packaging

guar anteeing a preservation period of 6 months with

land or air transport, or after transport by ship to

neighbouring conti nents (without crossing the tropics).

3.2

Handling

Avoid any impacts on the equipment so as not

to alter their performance.

Never carry the equipment by the electrical

supply cable.

3.3

Installing

E320 are delivered with bore / tolerance H7 and keyway/

tolerance P9 according to NFE22175 / DIN6885 /

ISO R773 / BS 4235. The mobile plate assembly (353)

is delivered with bore / tolerance H7. We recommand to

use tolerance h6 for shaft and g6 for the mobile toothed

ring assembly (352).

The pin should not generate any stress on the bearings.

In case of vibrations, it is strongly recommended to

insert a damping elastic slot between the anti-rotation

device and the anti-rotation slot and to fix the coil’s

cable the nearest of it to avoid whipping.

In the case where two co-axial shafts are

fitted, the recommended setover is 0,05 mm

maximum.

The angular misalignment should not be greater than

0,1 mm over a length of 100 mm. If this is the case,

use a VAR05 (flexible coupling).

3.3.1 Installing VAR00/VAR04/VAR10/VAR14

•

Center the mobile toothed ring assembly (352) or the

mobile plate (353) on the driven part, then fix it

with screws and lock them

•

After adjusting the driving key, mount inductor on

the shaft and fix it axially onto the shaft

It is important to tighten the locking screws from

mobile toothed assembly to the specified torque

(see table 2) or to the mobile plate (353) and secure

them with loctite 243 or an equivalent product.

While assembling the driving and driven parts,

it is essential to note the value J (which is the

distance between tooth heads), see Table 1.

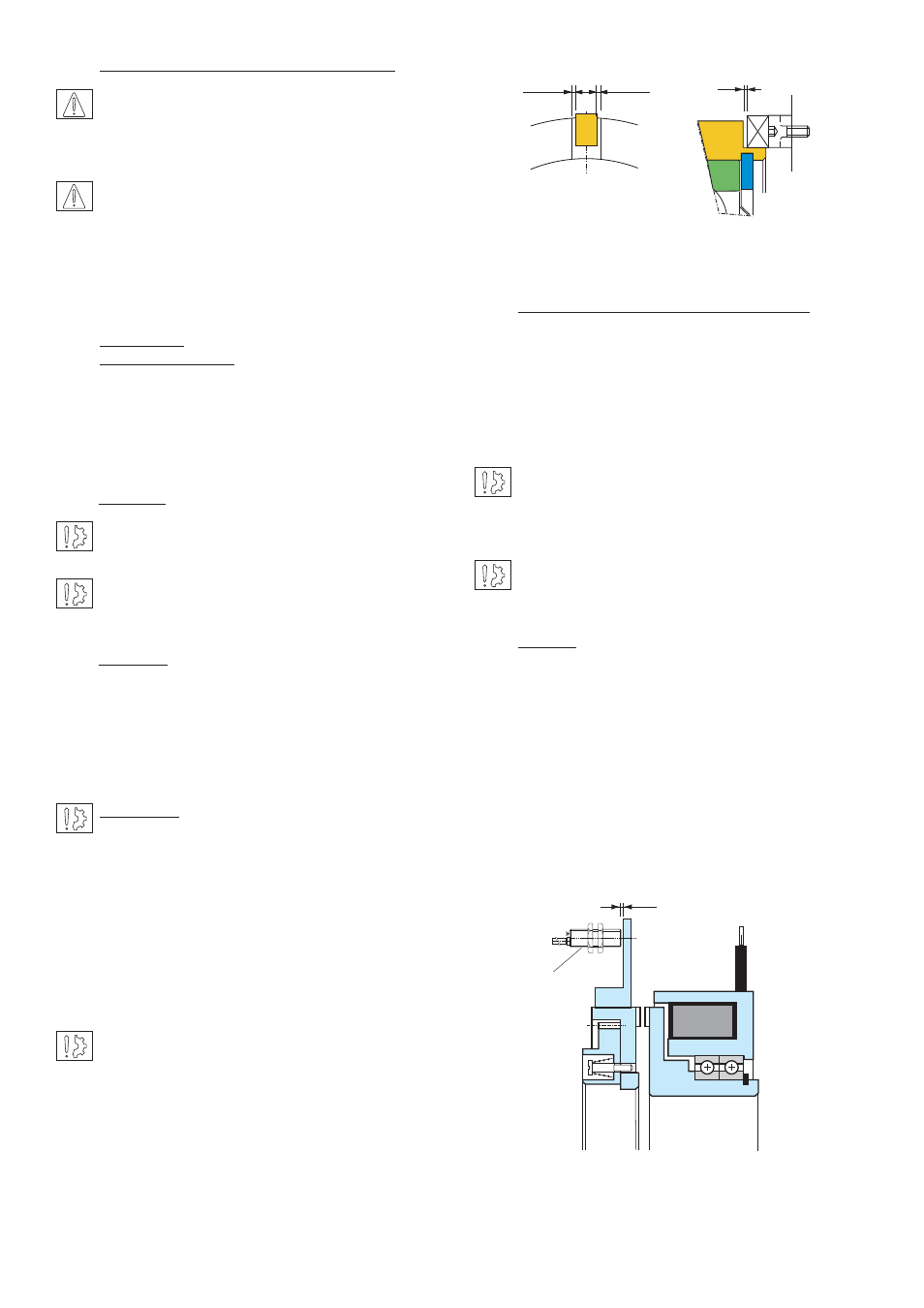

3.3.2 VAR504

Detection discs (aluminium or steel) compatible with

induc tive proximity sensor are provided with unit.

The position of the sensor should not obstruct the

travel of the toothed flange (352) (353).

We suggest to use the inductive sensor (615) provided

by our company, (see technical form).

MOUNTING EXAMPLE

1

0,25

0,25

Fig. 1

Sensor

Airgap

Any modification made to the brake without

the express authorisation of a representative

of Warner Electric, in the same way than any use out

of the contrac tual specifications accepted by “Warner

Electric”, will result in the warranty being invalidated

and Warner Electric will no longer be liable in any way

with regard to conformity.

Important: It is important to prevent inductor

(101) from rotating. It is the customers

responsibility to supply means to prevent inductor

rotating. i.e. retention pin in slot.Check gaps between

the inductor and the retention pin (see Figure 1) :

minimum 0,5 mm gap -1 mm gap at the slot bottom.