Warner Electric ERDD User Manual

Page 3

Warner Electric Europe • +33 (0)2 41 21 24 24

P-2062-WE • 2/13 3

Use the handling

holes provided for

any operation (See

Fig. 1, table 1).

Never transport

the unit by the

cable.

2.2

Precautions and safety measures

During the maintenance period make sure

that the moving parts of the machine are

stationary and that there is no risk of start-up.

All intervention have to be made by qualified

personnel, owning this manual.

It is imperative that the release screws (903) are

mounted before any operation is made to the

unit.

Any modification made to the brake without

the express authorisation of a representative of

Warner Electric, in the same way than any use

out of the contrac tual specifications accepted

by “Warner Electric”, will result in the warranty

being invalidated and Warner Electric will

no longer be liable in any way with regard to

conformity.

3

Installation

3.1

Transport / storage

These units are delivered in packaging that

guarantees a 6 months storage period whether

transported by land, by air, or by sea to any

destination excepting tropical countries. (For

tropical destinations please consult Warner

Electric technical services).

3.2

Handling

The unit is supplied pre-assembled except for

the hub.

Do not expose the unit to shocks whilst

handling as this may reduce performance.

3.2

Installation

To

mount the unit proceed as follows: according

to types, (see appendices 1 or 2):

Compress springs with release screws (903).

The moving armature (330) must be pulled

against the inductor (101).

Loosen the locking screws (909), the friction

plate (348), the friction disc(s) (312) and the

intermediate disc (320) or (321) for brakes with

dual discs.

Slide the hub (515) onto the shaft to be braked,

fit the driving key and secure it axially.

Keep the driving splines free of oil (i.e. friction

disc / hub). Otherwise this may reduce

performance.

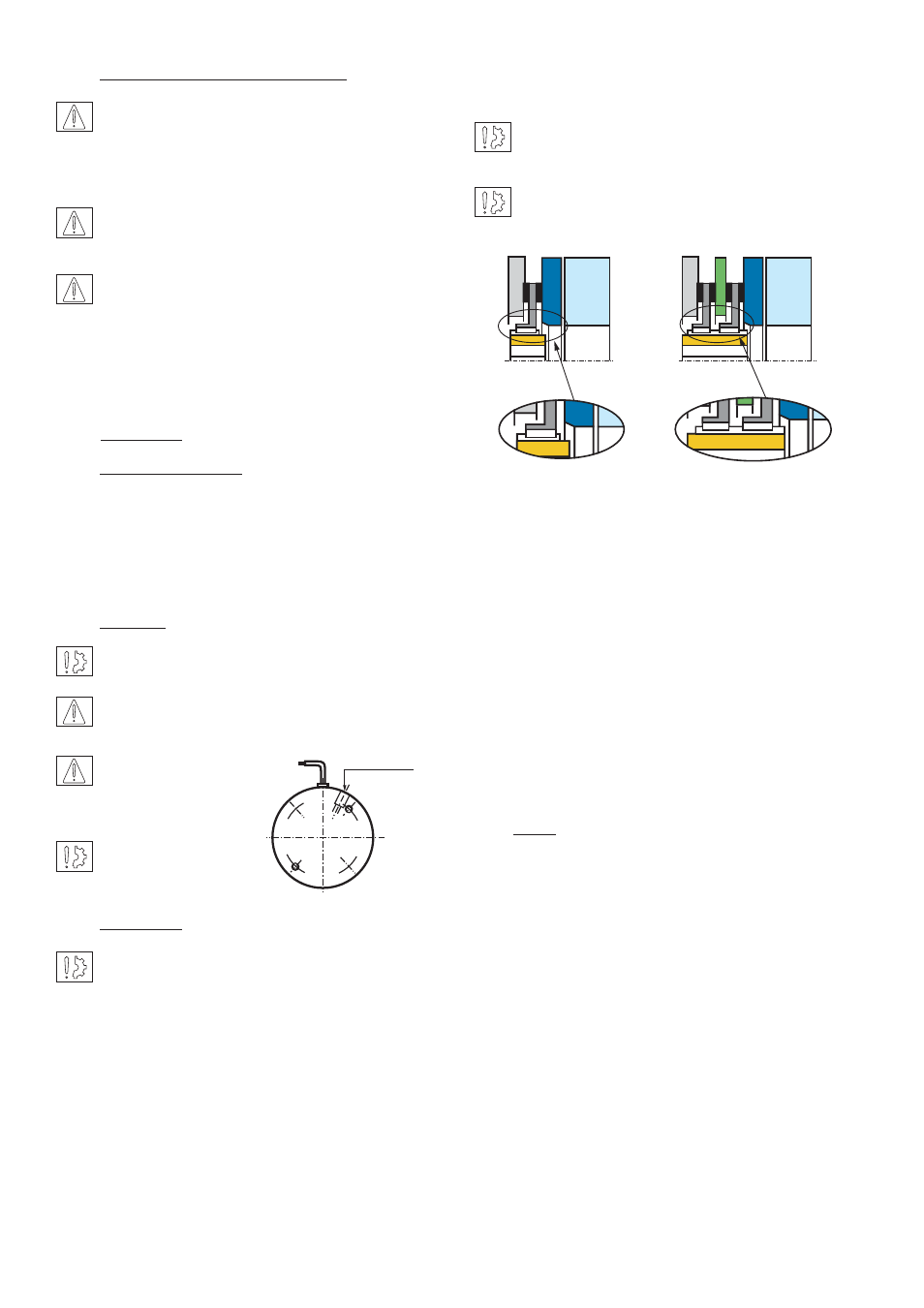

It is important to note the hub mounting

directions (See Fig. 2).

The hub is normally supplied with the following

norms : tolerances H7 for bore, P9 for keyways

(According to NF E 22-175/DIN 6885/BS 4235/ISO

R773).

Fit the friction plate (348) onto the mounting

surface. For single disc brakes from size 3200 and

for dual disc brakes from size 6400, the friction

plate is directly fixed on the mount with CHC

screws (not provided) and secure them with a

LOCTITE 270 product.

Now install the friction disc (312). If this is a dual

disc brake, then fit the intermediate disc (320) or

(321) and finally install the second friction disc

(according to size).

NOTE: The angle of the friction discs must be

facing the friction plate (see Fig. 2).

Slide the pre-campled moving armature (330) /

inductor (101) between the friction faces and fix

it with locking screws (909) and washers noting

carefully the tightening torque (see table 1 page 2).

Remove release screws (903). Energize the unit

(see chapter 5) and check if the friction disc

rotates freely.

Energise the brake a number of times whilst the

motor is static and check the nominal airgap value

(See table 1 page 2) near the faces of the friction

plate (348). If insufficient airgap, see chapter 4

(maintenance)

Fig. 1

Handling

screw

ERD

ERDD

Fig. 2