Warner Electric ERDD User Manual

Page 2

2 Warner Electric Europe • +33 (0)2 41 21 24 24

P-2062-WE • 2/13

We,

WARNER ELECTRIC EUROPE, 7, rue Champfleur, B.P. 20095, F-49182 St Barthélemy d’Anjou Cedex

declare that these brakes are made in our factory from St Barthélemy d’Anjou,

and hereafter designated :

ERD and ERDD

are exclusively designed for incorporation into a machine and to be assembled with other equipments to create a machine. The operation of the

product is submitted to the conformity of the complete equipment, following the provisions of the machinery directive 98/37/EC and if electric

to the EMC directive 89/336 /EEC. The conformity of the electric units to the Low Voltage directive 72/23 is supported by the full respect of the

following standards : NFC 79300 and VDE 05808/8.65.

Drawn up in St Barthélemy d’Anjou, July 2002

E. PRAT, General Managing Director

CONTENTS

1

Technical specifications

2

2

Precautions and restrictions on use

2

2.1

Restrictions on use

2

2.2

Precautions

3

and safety measures

3

Installation

3

3.1

Transport - storage

3

3.2

Handling

3

3.3

Installing

3

4

Maintenance

4

4.1

Adjusting the airgap

4

1

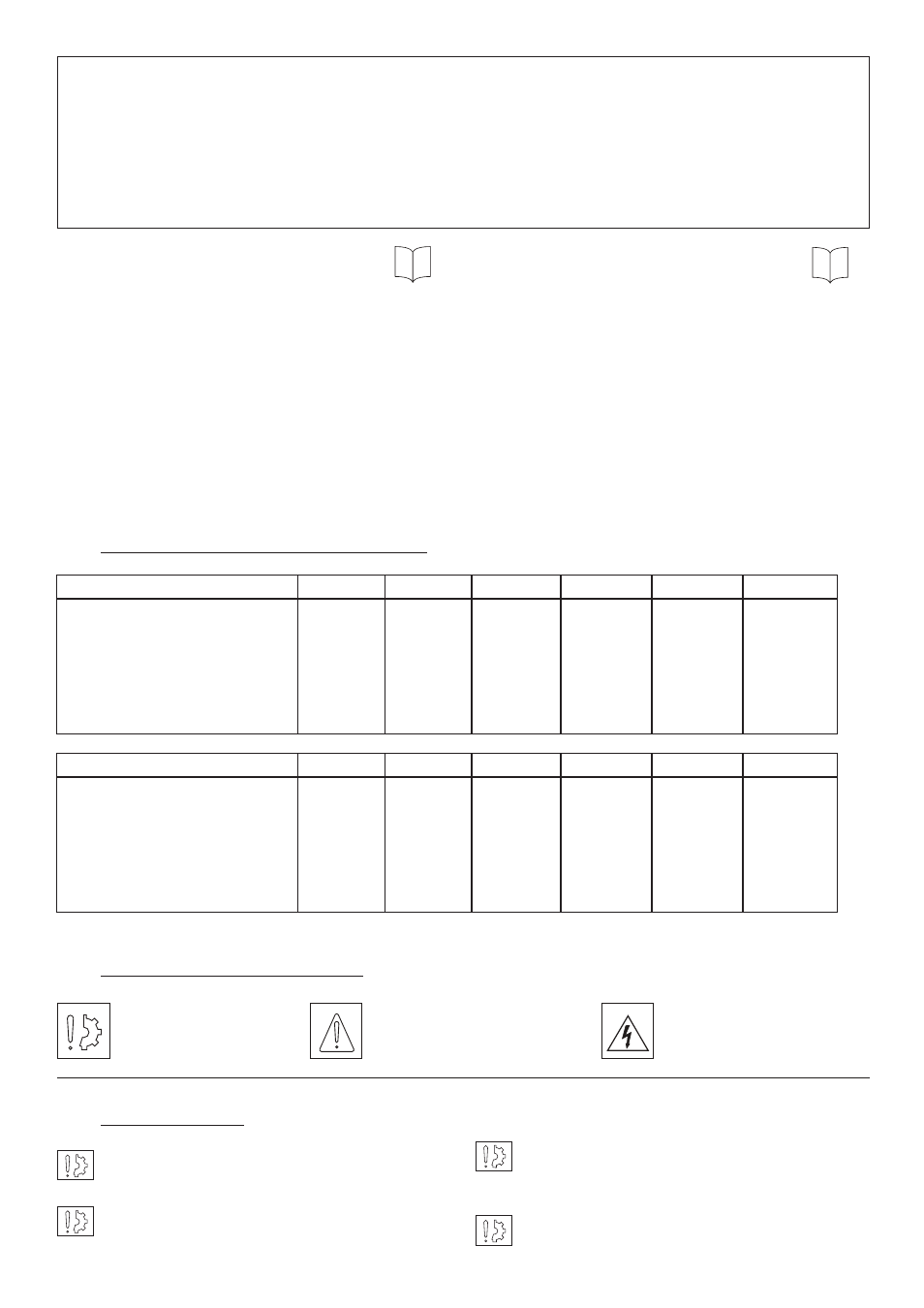

Technical specifications (VAR00 and VAR03)

ERD Size

500

800

1600

3200

6400

12800

Nominal airgap

mm

Airgap tolerance

mm

Pull-in airgap max.

mm

Tightening torque screw 909 Nm

Number of screws (Rep. 903)

-

Handling Screws

-

Allowable wear max*

mm

0,4

± 0,005

1

48(±10%)

2xM10x80

M8

4

0,6

+0,05/-0,1

1,5

48(

±10%)

4xM12x90

M12

4

0,6

+0,05/-0,1

1,5

110(

±10%)

3xM16x110

M12

6,5

1

±0,1

2

150(±10%)

8xM20x120

M16

9

1,3

±0,15

2,5

260(±10%)

8xM20x140

M16

10

1,5

±0,15

3

380(±10%)

8XM20X180

M20

14,7

4.2

Adjusting the detector

4

5

Electrical connection

4

5.1

Important recommendations

4

5.2

Power supply

4

6

Options

5

6.1

Torque adjustment

5

6.2

Detection kit

5

7

Appendices

6-7

7. 1

Appendix 1 (ERD 500 to 1600 and

6

ERDD 1000 to 3200)

7. 2

Appendix 2 (ERD 3200 to 12800 and

7

ERDD

6400 to 25600)

ERDD Size

1000

1600

3200

6400

12800

25600

Nominal airgap

mm

Airgap tolerance

mm

Pull-in airgap max.

mm

Tightening torque screw 909 Nm

Number of screws (Rep. 903)

-

Handling Screws

-

Allowable wear max*

mm

0,5

± 0,05

1

48(±10%)

2xM10x80

M8

9

0,7

+0,05/-0,1

1,5

48(

±10%)

4xM12x90

M12

10,5

0,7

+0,05/-0,1

1,5

110(

±10%)

3xM16x110

M12

13,5

1,3

±0,1

2

150(±10%)

8xM20x120

M16

16,5

1,7

±0,15

2,5

260(±10%)

8xM20x140

M16

15

1,9

±0,15

3

380(±10%)

8XM20X180

M20

15,5

Table 1

*See paragraphs 4-2 and 4-3

2

Precautions and restrictions on use

2.1

Restrictions on use

These units are designed for dry operation. The

brake must be free from oil and grease.

Exceeding the maximum rotation speed listed in

the catalogue will invalidate the guarantee.

ERD 500, ERD 800 and ERD 1600 can be hori-

zontally or vertically mounted, all other units can

only be mounted horizontally.

Ambient temperature for these units is

max 40° C (insulation class of 155°C).

Symbol designating

an action that might

damage the brake

Symbol designating an

action that might be

dan gerous to human safety

Symbol designating an

elec trical action that might be

dangerous to human safety