Warner Electric ERDD Sizes 120 to 600 User Manual

Page 3

Warner Electric Europe • +33 (0)2 41 21 24 24

P-2064-WE • 2/13 3

3

Installation

3.1

Transport / storage

These units are delivered in packaging that

guarantees a 6 months storage period whether

transported by land, by air, or by sea to any

destination excepting tropical countries. (For

tropical destinations please consult Warner

Electric technical services).

3.2

Handling

Avoid any impacts on the equipment so as not

to alter their performance.

Never carry the equipment by the electrical

supply cable.

3.3

Installing

NB : ERD SZ060 to 300 brakes are supplied in

kit form. The Mounted inductor is supplied

airgap adjusted.

The ERDD HT brakes are delivered completely

mounted, the airgap is adjusted in our

workshop. See chapter 7 (appendix)

If a friction flange (341) is supplied, fix it first.

Put the key into the shaft then slide the hub

(515) onto the shaft and stop it axially by

suitable means.

Slide the friction disc (312) or (315) onto the

hub.

Fit the mounted inductor (107) or (108), remove

the wedge pieces (551) and fix it using the

fixing bolts (913) or (914).These screws have

to be tightened (see torque table 1). Secure the

bolts using a LOCTITE 270 type thermoplastic

liquid.

If a hand locking kit is supplied, it is preferable

to adapt it on the mounted inductor before the

inductor is fitted. (See chapter 6)

If a dust cover (555) is supplied, carefully slide it

onto the equipment before fitting it.

Switch

the equipment on and confirm that the

friction disc rotates freely.

Make several motor manoeuvres stationary and

check the value of the airgap.

If the airgap is insufficient, refer to chapter 4

(maintenance)

Do not grease the guiding splines (friction

disc / hub). It will change the brake’s

performances.

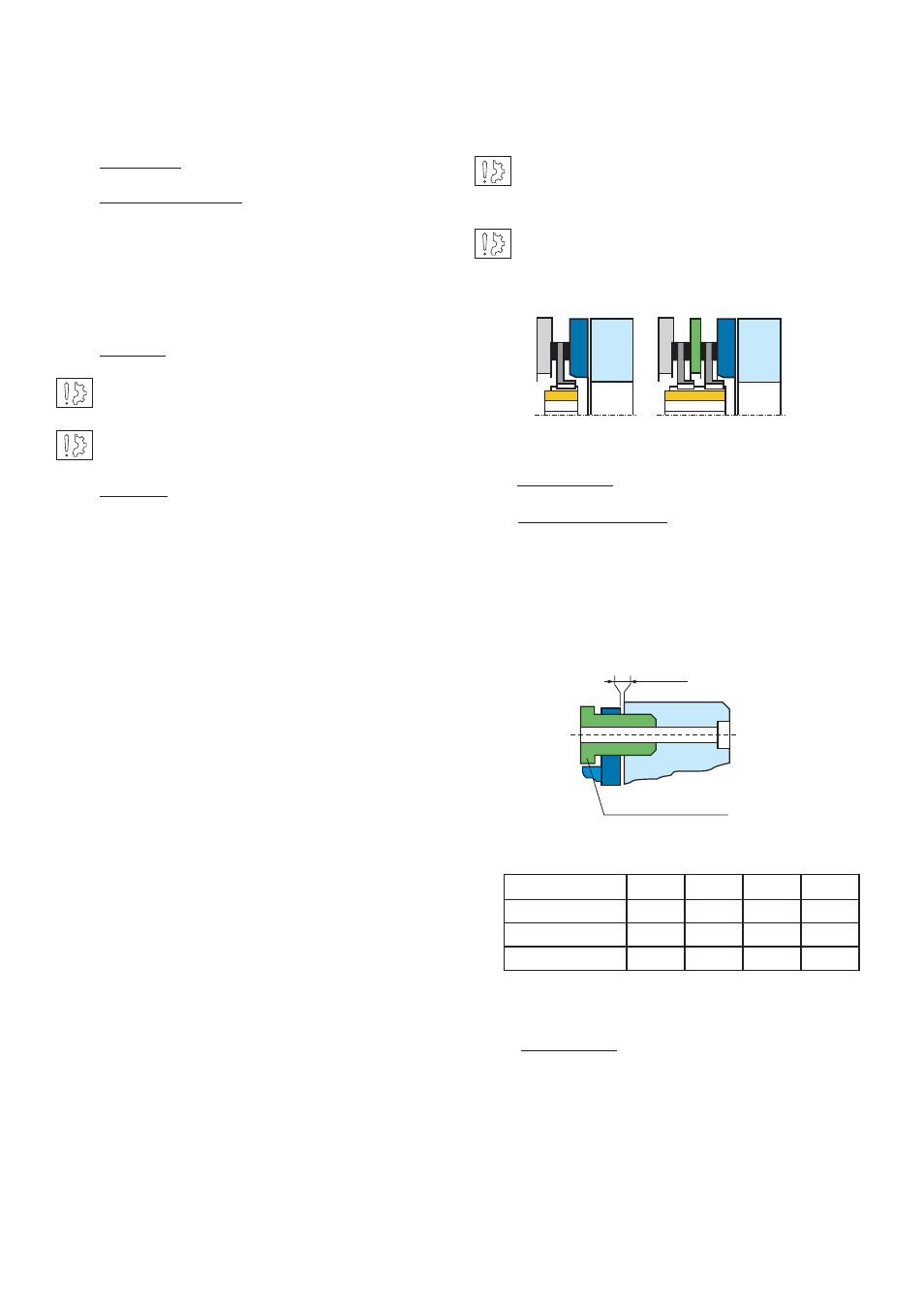

WATCH OUT ! Respect obligatory the direction

of the hub when mounting (see fig. 1 below)

4

Maintenance

4.1

Adjusting the airgap

To

adjust the airgap (Fig. 2), undo the adjustment

bolts in order to get the necessary value (see table

1). Check the value of the airgap at several points.

Make several motor manoeuvres stationary, then

again check the value of the airgap.

4.2

Maintenance

Wear in the friction material causes an increase

in the air gap. Before reaching the maximum

airgap (see table 1), it is necessary adjust it (see

above).

Fig. 1

ERD

ERDD HT

Table 2

Adjusting screw

Airgap

Fig. 2

ERD Size

060

100

170

300

E min (mm)

6

6

7,7

8

ERDD HT Size

120

200

340

600

E min (mm)

11,2

10

12,7

12,3