Warner Electric ERDD Sizes 120 to 600 User Manual

Page 2

2 Warner Electric Europe • +33 (0)2 41 21 24 24

P-2064-WE • 2/13

We,

WARNER ELECTRIC EUROPE, 7, rue Champfleur, B.P. 20095, F-49182 St Barthélemy d’Anjou Cedex

declare that the brakes herein made in our factory from St Barthélemy d’Anjou,

ERD and ERDD

are intended to be incorporated in an installation or to be assembled with other equipment with a view to constituting a machine to which

directive 89/336 as amended apply.

The basic requirements of Low Voltage directive 73/23 as amended are compiled with through full conformity with the following standards:

NFC 79300 and VDE 05808/8.65

Drawn up in St Barthélemy d’Anjou, July 2002

E. PRAT, General Managing Director

CONTENTS

1

Technical specifications

2

2

Precautions and restrictions on use

2

2.1

Restrictions on use

2

2.2

Precautions and safety measures

2-3

3

Installation

3

3.1

Transport - storage

3

3.2

Handling

3

3.3

Installing

3

4

Maintenance

3

4.1

Adjusting the airgap

3

4.2

Maintenance

3

4.3

Spare parts

4

5

Electrical connection

4

5.1

Important recommendations

4

5.2

Power supply

4

6 Options

4

6.1

Torque adjustment

4

6.2

Detection kit

5

6.3

Hand release kit

5

7

Appendices

6

7. 1

ERD VAR00 and VAR02

7

7.2

ERDD and options

7

1

Technical specifications VAR00, VAR02

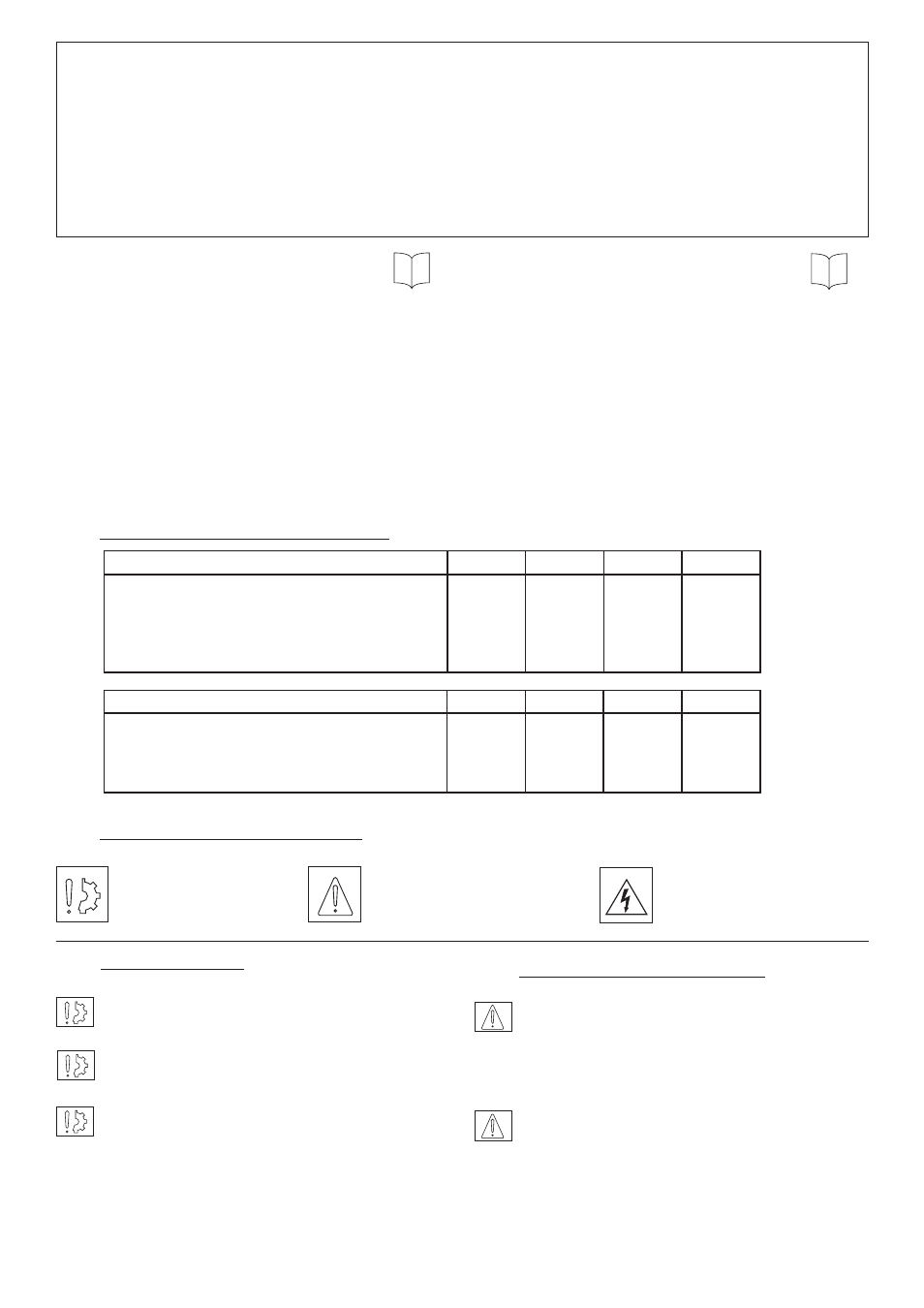

Table 1

ERD Size

060

100

170

300

Nominal torque (STANDARD version)

Nm

Nominal airgap +0,1/-0,05

mm

Pull-in airgap max.

mm

Nominal torque (HIGH TORQUE version) Nm

Tightening torque of screws

mm

60

0,3

0,8

80

24

100

0,3

0,9

130

24

170

0,3

0,9

220

24

300

0,3

1

400

48

ERDD HT Size

120

200

340

600

Nominal torque (HIGH TORQUE version) Nm

Nominal airgap +0,1/-0,05

mm

Pull-in airgap max.

mm

Tightening torque of screws

mm

160

0,3

0,8

24

260

0,4

0,9

24

440

0,4

0,9

24

800

0,4

1

48

2

Precautions and restrictions on use

2.1

Restrictions on use

The equipment is designed for dry

running.

Exceeding the maximum rotation speeds stated

in the catalogue invalidates the warranty.

The equipment can be fitted either horizontally or

vertically. The ERDD and HT version can only be

fitted horizontally.

This equipment is designed for an ambient

temperature of 40° maximum (155°C cladding

class).

2.2

Precautions and safety measures

During maintenance, ensure that the Mechanism

to be braked by the equipment is at rest and

that there is no risk of accidental start-up.

All intervention have to be made by qualified

personnel, owning this manual.

Any modification made to the brake without

the express authorisation of a representative of

Warner Electric, in the same way than any use

out of the contrac tual specifications accepted by

“Warner Electric”, will result in the warranty being

invalidated and Warner Electric will no longer be

liable in any way with regard to conformity.

Symbol designating

an action that might

damage the brake

Symbol designating an

action that might be

dan gerous to human safety

Symbol designating an

elec trical action that might be

dangerous to human safety