Warner Electric Electrically Released Brake ER-375, ER-475, ER-650 User Manual

Page 7

7

Warner Electric • 800-825-9050

P-253 • 819-0315

Fails to Release: If the Electrically Released

Brake does not release completely, make the

following checks:

1. Check that the electrical connections (polarity)

between the brake coil and the power supply

are correct for the power supply being used.

2. Connect a DC voltmeter across the brake

terminals. (Do not disconnect the leads to the

terminals.) The voltmeter should indicate a

voltage in the range of 75 to 110 volts.

3. The above checks are normally sufficient.

Further checks may be made by checking

the brake coil resistance.

a. Turn off the power to the brake.

b. Disconnect one lead from the coil to make

sure the circuit is open.

c. Connect an ohmmeter across the brake

terminals. The resistance should be as

shown:

Brake

Coil Resistance

Size

at 20°C (±10%)

ER-375

447 OHMS

ER-475

310 OHMS

ER-650

235 OHMS

A very high or infinite resistance reading would

indicate an open coil. A very low resistance

would indicate a shorted coil. In either case, the

unit should be replaced.

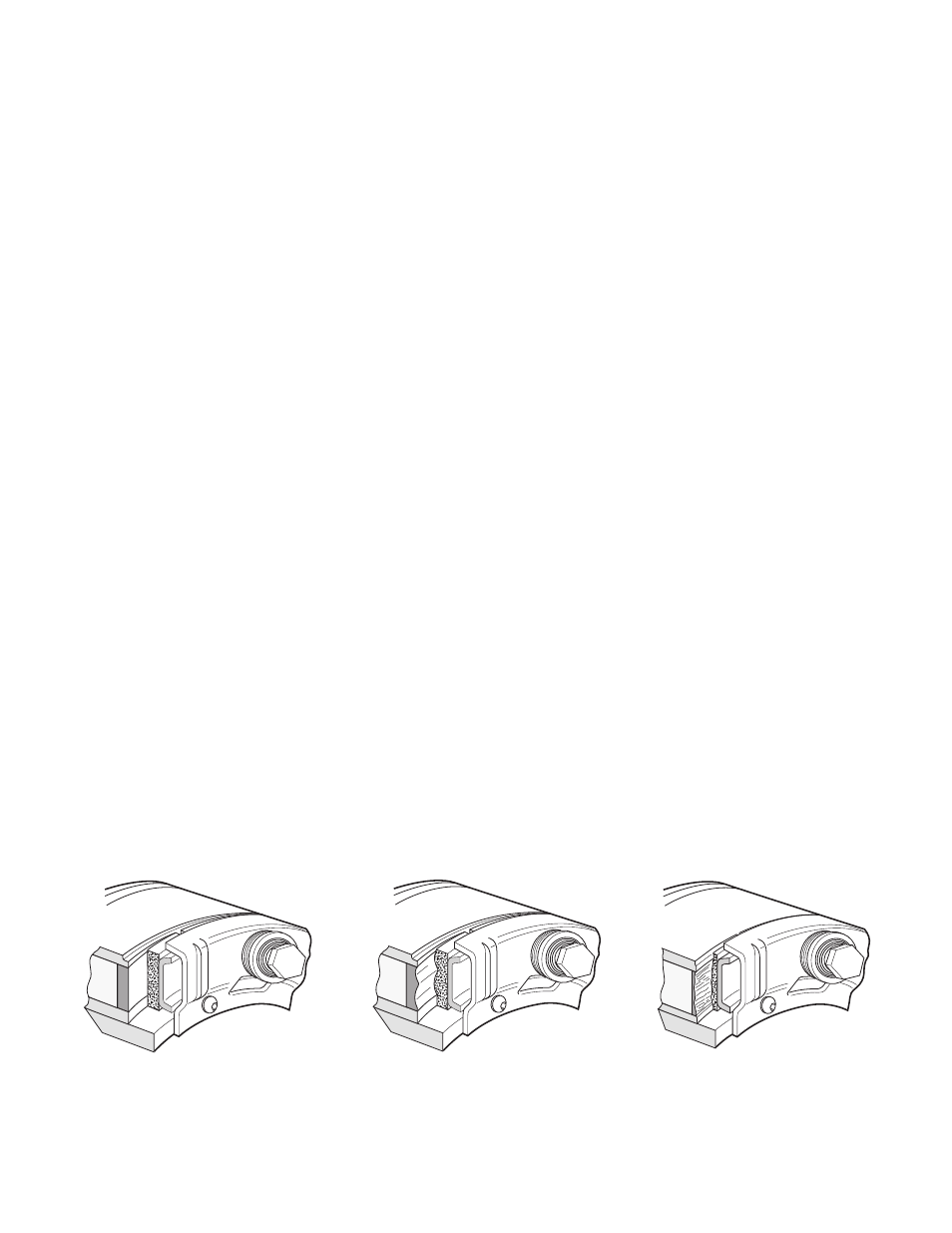

Wear Pattern

New

Burnished

Worn

Wear Pattern: (See Figure 5) Wear grooves appear

on the friction surfaces. This is a normal wear

condition, and does not impair functioning of the

unit. Never machine the friction surfaces to remove

grooves or score marks resulting from normal wear.

There are two main wear parts, magnet and

armature. When either is worn out, the complete

brake must be replaced.

Heat: Excessive heat and high operating

temperatures are causes of rapid wear. Air should

be allowed to circulate around the unit as efficiently

as possible, especially if the application requires

fast, repetitive cycle operation.

If the above checks indicate that the proper voltage

and current is being supplied to the coil, mechanical

parts should be checked to assure that they are in

good operating condition and are properly installed.

Figure 5