Warner Electric Electrically Released Brake ER-375, ER-475, ER-650 User Manual

Page 5

5

Warner Electric • 800-825-9050

P-253 • 819-0315

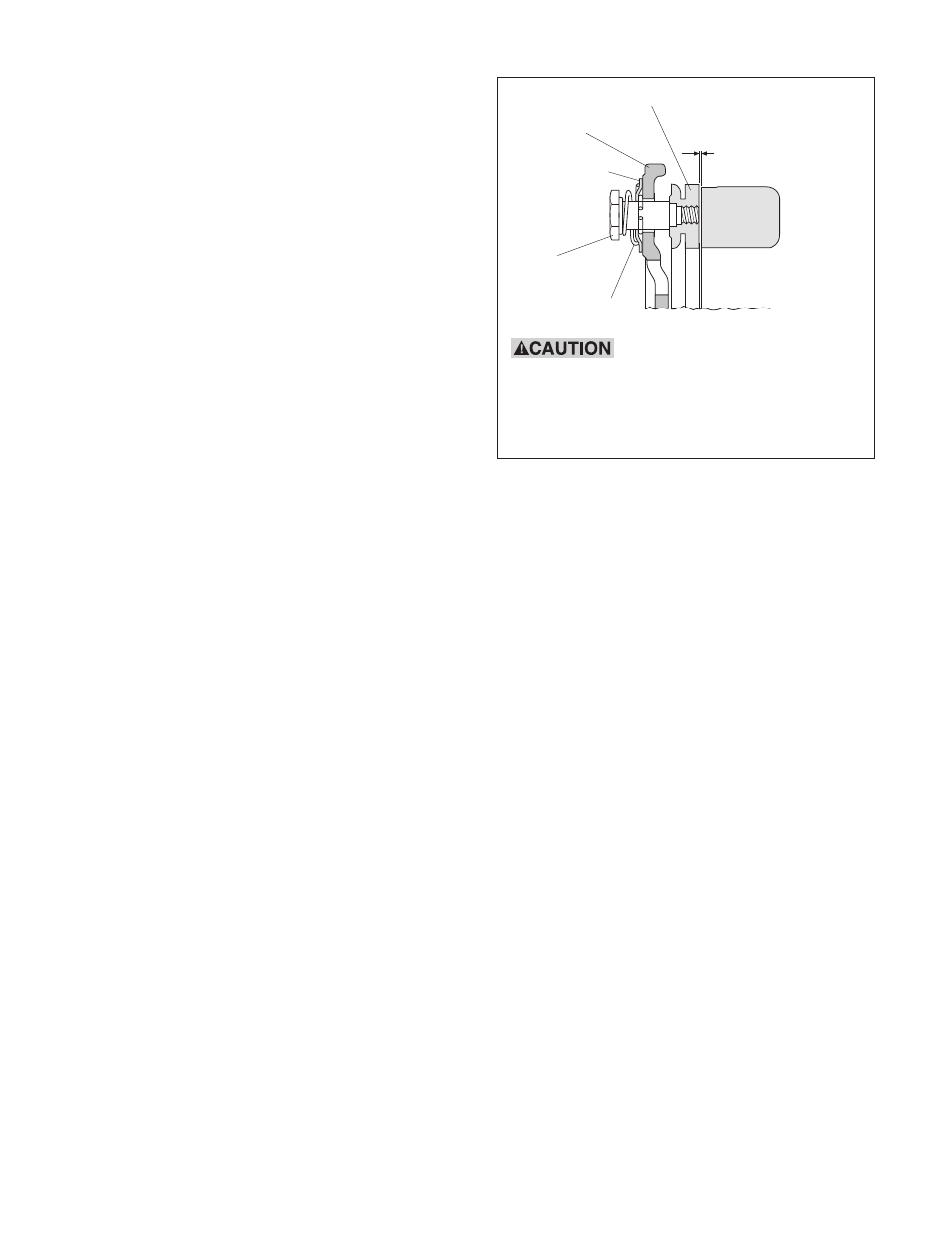

Armature

Carrier

Detent Spring

Retainer

Drive Pin

Detent Spring

Armature Spring

Back 1/32-inch

Magnet

Figure 4

A. With the brake power on, pull gently on the

O.D. of the armature to separate it from the

magnet by a 1/32-inch or greater airgap.

Do not pry. This could damage the

components.

B. Slide the detent spring retainer on each

drive pin until it bottoms against the carrier.

If armature cannot be moved, check voltage

and polarity. (See Operating Instructions

"Fails to Release" on page 7.)

C. Push against the drive pins to push the

armature into contact with the magnet.

D. Release the drive pins and the armature will

spring back approximately 1/32-inch. The

armature gap will now be provided by the

autogap mechanism.

5. Continue to slowly increase the applied

voltage until the armature re-engages the

magnet. If the maximum voltage available from

the supply does not cause the armature to

re-engage, the armature should be manually

assisted into engagement.

Note: If armature needs to be manually

assisted, armature should be pressed on

back side to make contact with friction face

of magnet.

6. With the armature re-engaged, slowly reduce

the applied voltage until the armature

disengages from the magnet. Note and

record the applied voltage at this point.

7. The optimum release point for the brake is

half-way between the two recorded voltage

readings. Adjust the supply to this optimum

release voltage.

Note: The above procedure should be done by

visually watching the armature move and may be

repeated if necessary from Step 1 through Step

7.

If you have any problems during adjustments or

any application questions arise, please contact

Technical Support at 1-800-825-9050 Monday

through Friday 7:30 a.m. - 4:30 p.m. central time.

F. Autogap Adjustment

Turn the power on to electrically release the brake.

The armature should spring back approximately

1/32-inch as shown.

If the armature does not spring back, follow

the autogap adjustment procedure as follows:

(refer to Figure 4).

Keep fingers clear of area

between the magnet and the armature

because the armature will be pulled sharply

toward the magnet if the release voltage

is altered for any reason.