Warner Electric Autogap 825-1525 Special Heavy Duty User Manual

Page 3

3

Warner Electric • 800-825-9050

819-0312

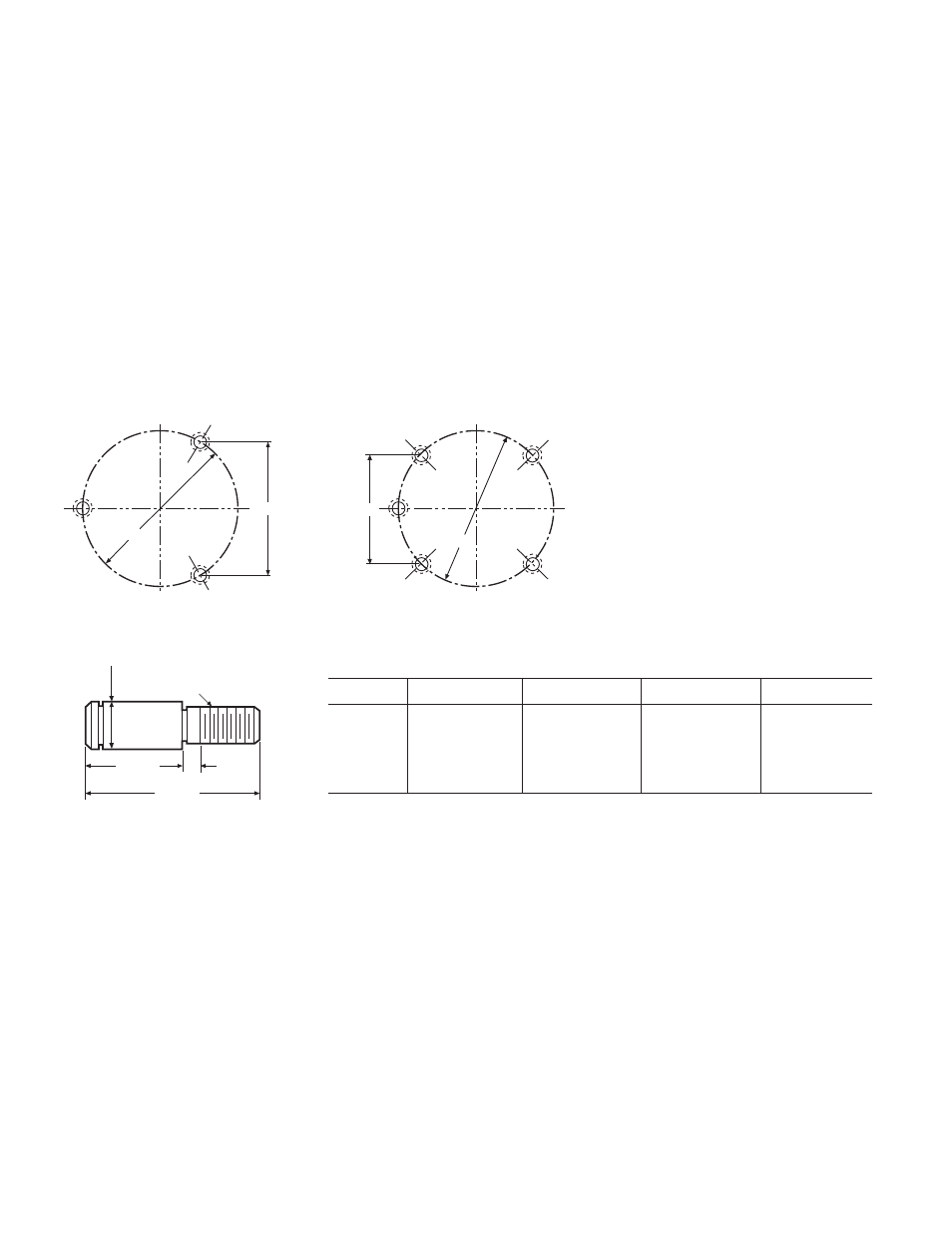

1. Chordal dimensions “A” or “C” must be held

for all chords between pin holes.

2. Drill 27/64 inch diameter holes to a sufficient

depth and tap 1/2-13 UNC-3B one inch min-

imum full threads. Pin holes must be square

with plane of mounting surface and magnet

mounting.

3. Ream .500/.501 to a 3/8 inch depth and to

be concentric with tapped holes.

B

A

C

D

1/2-13 UNC-3A

THDS .

5/16"

1-9/32"

2-1/4"

.6185 Dia.

+.0005

-.0010

Drive Pins Should be Retained

with Sealant

Before installing the drive pins, apply a good

grade of thread sealant such as Loctite

®

, or

equivalent, to the threaded portion only.

Caution must be taken to prevent the sealant

from getting on the bearing surface of the pin.

Tighten all pins securely by inserting an Allen

wrench in the socket provided.

Machining Instructions for Gear, Sprocket, or Pulley

For Sizes 825 through 1525

Unit Size

A

B

C

D

825

3.085 ± .001

3.563 ± .001

1000

4.548 ± .002

5.252 ± .002

1225

4.155 ± .002

5.877 ± .002

1525

6.010 ± .002

8.500 ± .002

- UNIBRAKE NEMA 4 (6 pages)

- UNIBRAKE (8 pages)

- ARC 2000 (16 pages)

- ARC Clutch_ZRC Top Load (18 pages)

- ZRC Clutch_ARC Top Load (18 pages)

- Dairy Cap Chuck (24 pages)

- Dairy Capping Headsets (10 pages)

- Autogap 475 & 650 (4 pages)

- Brushholder Installation (2 pages)

- Autogap 825-1225 (2 pages)

- Electro-Packs EP-170, 250, 400, 500, 825, 1000, 1525 (20 pages)

- Electro-Brake 375, 475, 650, 825, 1000, 1225 (20 pages)

- Electro-Clutch EC-375, EC-475, EC-650, EC-825, EC-1000, EC-1225 (20 pages)

- 5300-101-001 Collector Ring (2 pages)

- 5301-101-010 Collector Ring (2 pages)

- Brushholder Assembly and Mounting Dimensions (2 pages)

- SF_PB 400 (2 pages)

- SF_PB 250 (2 pages)

- Autogap 825-1525 (4 pages)

- Electro-Module EM-50, EM-100, EM-180, EM-210, EM-215 (22 pages)

- FB-375, 475, 650 (14 pages)

- 5200-101-012 Conduit Box Kit (4 pages)

- 5200-101-011 Conduit Box Kit (4 pages)

- 5200-101-010 Conduit Box Kit (4 pages)

- Recommended Electrical Installation Procedure for Warner Electric Clutches and Brakes (2 pages)

- EP-400 Vertical Mounting (2 pages)

- EP-250 Vertical Mounting (2 pages)

- Autogap 500 (4 pages)

- ER 825 and 1225 Normal Duty (16 pages)

- ER 825 and 1225 Heavy Duty (14 pages)

- ERS Electrically Released Brakes (6 pages)

- AT Brakes & Clutches Complete Brake Repair – On the Shaft, Sizes 25, 55, 115 (4 pages)

- AT Brakes (6 pages)

- AT Brake–Major Service Repair Instructions for Sizes 25, 55, 115 (9 pages)

- AT Clutch – Major Service Sizes 25, 55, 115 (12 pages)

- 5162-101-002 Conduit Box Kit (6 pages)

- Electrically Released Permanent Magnet Clutch Compatible Modules (4 pages)

- Electrically Released Motor Brake Module for EM-MBFB and EUM-MBFB (6 pages)

- Electrically Released Brake Module For EM-FBB and EUM-FBB (4 pages)

- Electrically Released Brake ER-375, ER-475, ER-650 (12 pages)

- 5370-101-042 Conduit Box Kit (4 pages)

- Preassembled Clutch_Electrically Released Brake Module (7 pages)

- EUM-50_EUM-100_EUM-180_EUM-210_EUM-215 (16 pages)

- 5370-101-045 Conduit Box Kit (5 pages)