Warner Electric Autogap 825-1525 Special Heavy Duty User Manual

Page 2

2

Warner Electric • 800-825-9050

819-0312

Primary Brake

SF - Stationary

Unit

PB

Field Clutch

Part

Magnet

Armature

Rotor

Field

Armature

Check

.010 T.I.R.

.010 T.I.R.

.006 T.I.R.

.006 T.I.R.

.006 T.I.R.

Concentricity

Outside

Drive

Pilot Dia.

Outside

Drive

Diameter

Pins

I.D.

Diameter

Pins

.006 T. I. R.

.006 T. I. R.

Squareness

Outer Pole

.006 T. I. R.

Outer Pole

.006 T.I.R.

of Face

Face

of Face

Face

Step 6. Slide the armature and the hub with

taperlock bushing over the shaft until the face of

the armature contacts the face of the magnet or

rotor. Move armature assembly to provide a

clearance of 1/16 inch between the armature

face and magnet or rotor face.

The assembly should be checked by pressing

the armature into contact with the friction face

and then releasing the armature. The armature

should spring back approximately 3/64-inch.

This gap wilI be automatically maintained

throughout the life of the unit.

Note: During the assembly of the clutch or

brake components, the units must be checked

for concentricity and squareness to the shaft.

This is accomplished by using a dial indicator.

The following table gives the check points and

tolerances. (See Figure 5)

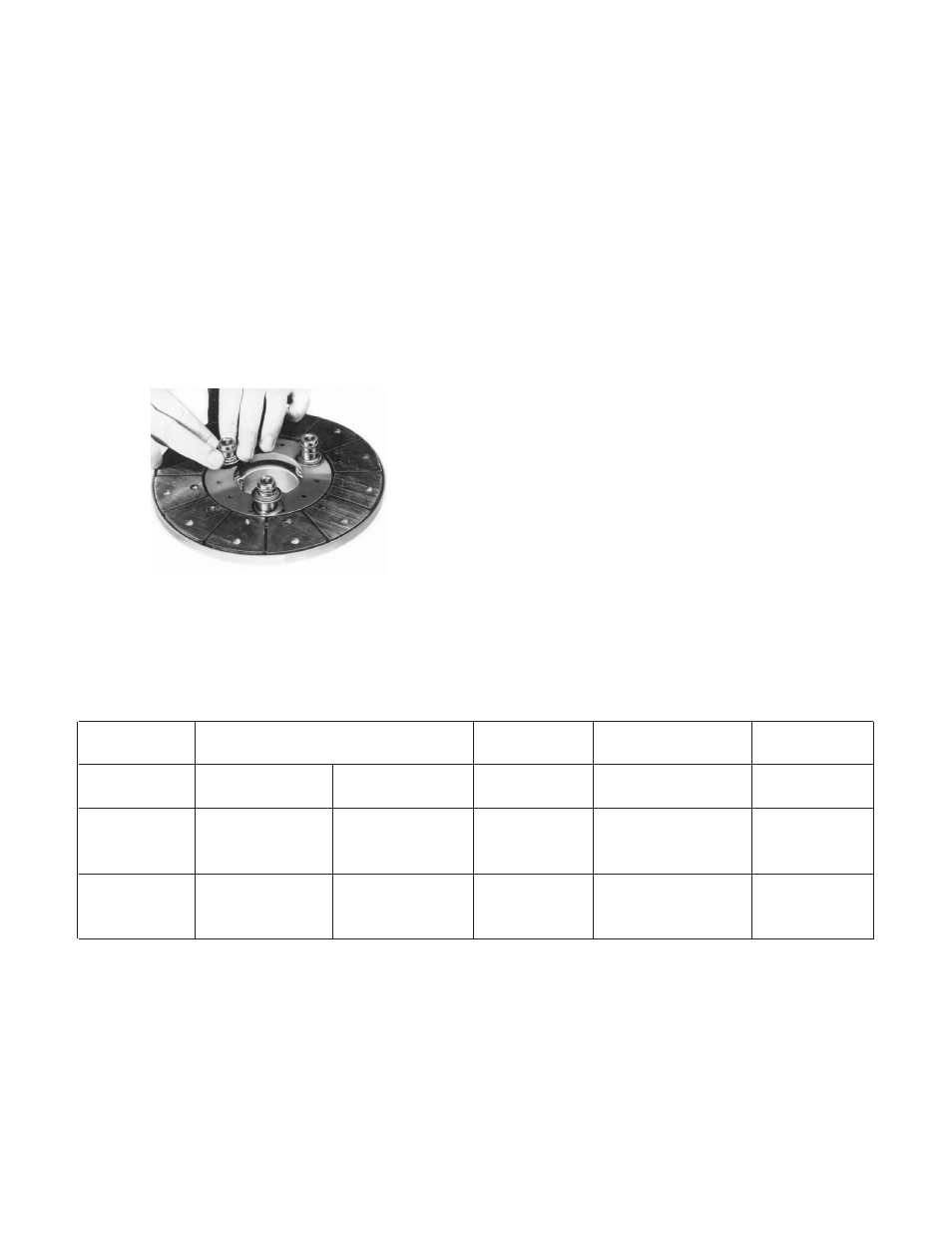

Step 4. Draw drive pins up tightly until shoulder

of pin is against face of hub (since threads are

class No. 3, pins may seem to bind).

Step 5. Check to see that the armature is com-

pletely compressed against the face of the hub.

To set the autogap, slide the detent spring

retainers against the armature face.

(See Figure 4)

Note: This position must not be disturbed dur-

ing completion of assembly.

Figure 4

(Figure 5) Tolerance Table