Warner Electric ER 825 and 1225 Heavy Duty User Manual

Page 4

4

Warner Electric • 800-825-9050

P-251 • 819-0121

Figure 2

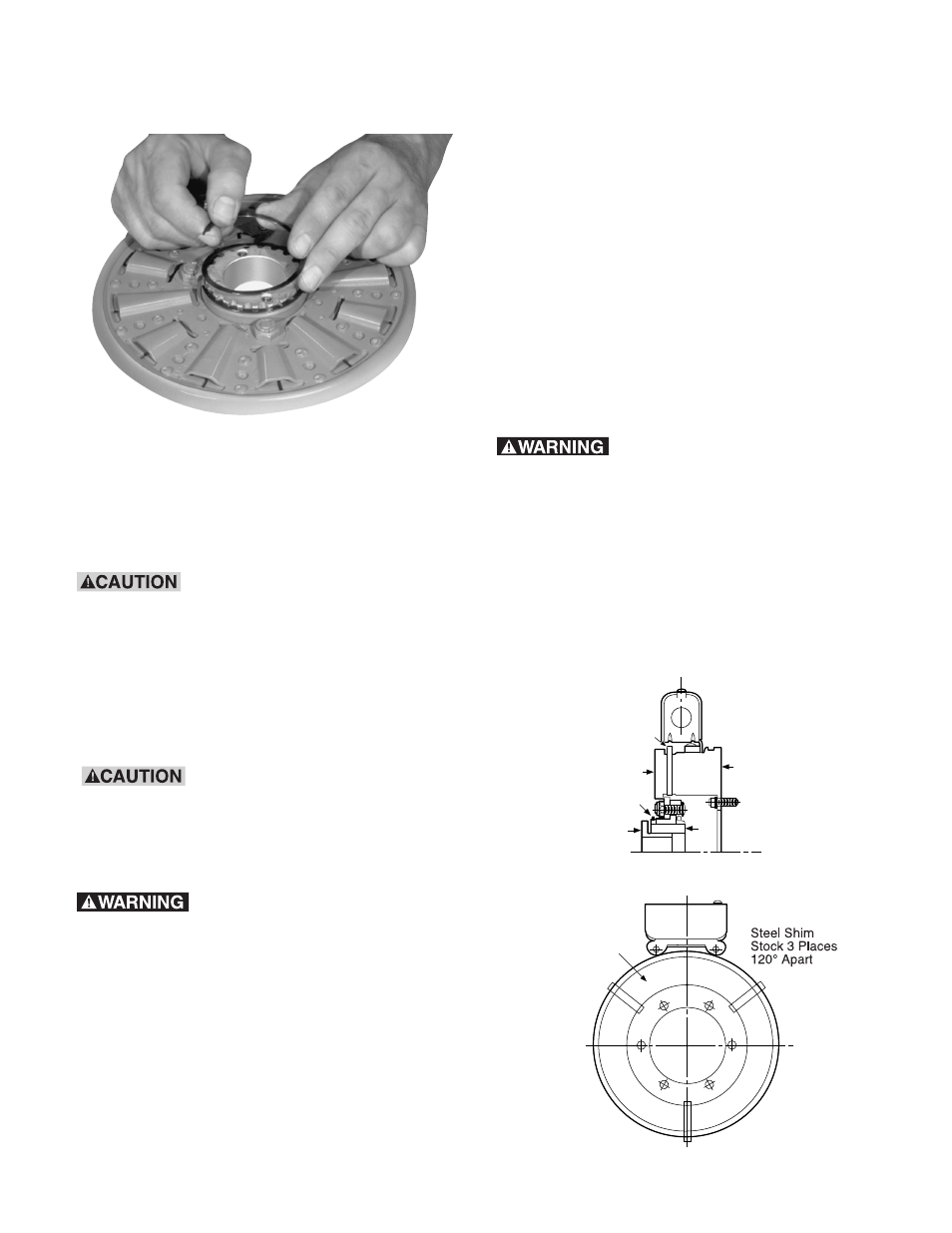

Step 3B:

Turn the assembly over and insert the

retainer ring in the groove. Take care not to bend or

distort retainer ring.

Step 3C:

Turn the assembly over and slide the

armature against the retainer ring.

During steps 4 through 7, handle

the armature/hub assembly by the hub (Figure

3, item 2) only, making sure the armature

(Figure 3, item 3) is as close to the retainer ring

(Figure 3, item 4) as possible. Any movement of

the armature on the splined hub will reduce

available armature travel and may cause

improper setting of the running air gap.

1/16 inch thick steel shims are

recommended for shim stock selection. Do not

use shims thicker than 1/8 inch or you will

shorten brake life by reducing available

armature travel.

Shim stock must be clean and

free of any contamination (oil, grease). Keep

fingers clear of the area between the magnet

and the armature as the armature will be pulled

sharply toward the magnet after the gap is

closed to approximately 1/2 inch.

Step 4:

Place three steel shims 120 degrees apart

on the magnet as shown in Figure 3. Insert the

taper-lock bushing (Figure 3, item 5) into the hub

(Figure 3, item 2).

Slip the armature hub assembly onto the brake

shaft until armature makes contact with shims.

Step 5:

Using a hex wrench, tighten the hub

bushing bolts alternately and evenly until tight.

Using a drift and small hammer, tap lightly at

several points around the circumference of the

taper lock bushing. Repeat this alternate tapping

and re-tightening until the specified torque is

reached and wrench no longer turns the screw after

tapping. Tighten bolts to the following:

Unit

Torque

Bushing Type

ER-825

87 in. lb.

Browning Series H

ER-1225

290 in. lb.

Browning Series Q

Do not attempt to pull the

bushing flange flush with the hub end as

there should be 1/8” to 1/4” clearance

when tightened.

The airgap between armature and magnet must be

.062 to .125 inch. If the airgap is outside of that

range, reposition the armature hub assembly by

repeating steps 1 and 2 of the disassembly

procedure and steps 4 and 5 of the assembly

procedure.

5

1

3

4

2

.062"

Thick

Steel Shims

Friction

Material

Figure 3

1

– Magnet

2

– Splined Hub

3

– Armature

4

– Spiral

Retainer Ring

5

– Bushing