0 micro series pid set point control – LEESON Micro Series Compact Inverters User Manual

Page 79

19.0 MICRO SERIES PID SET POINT CONTROL

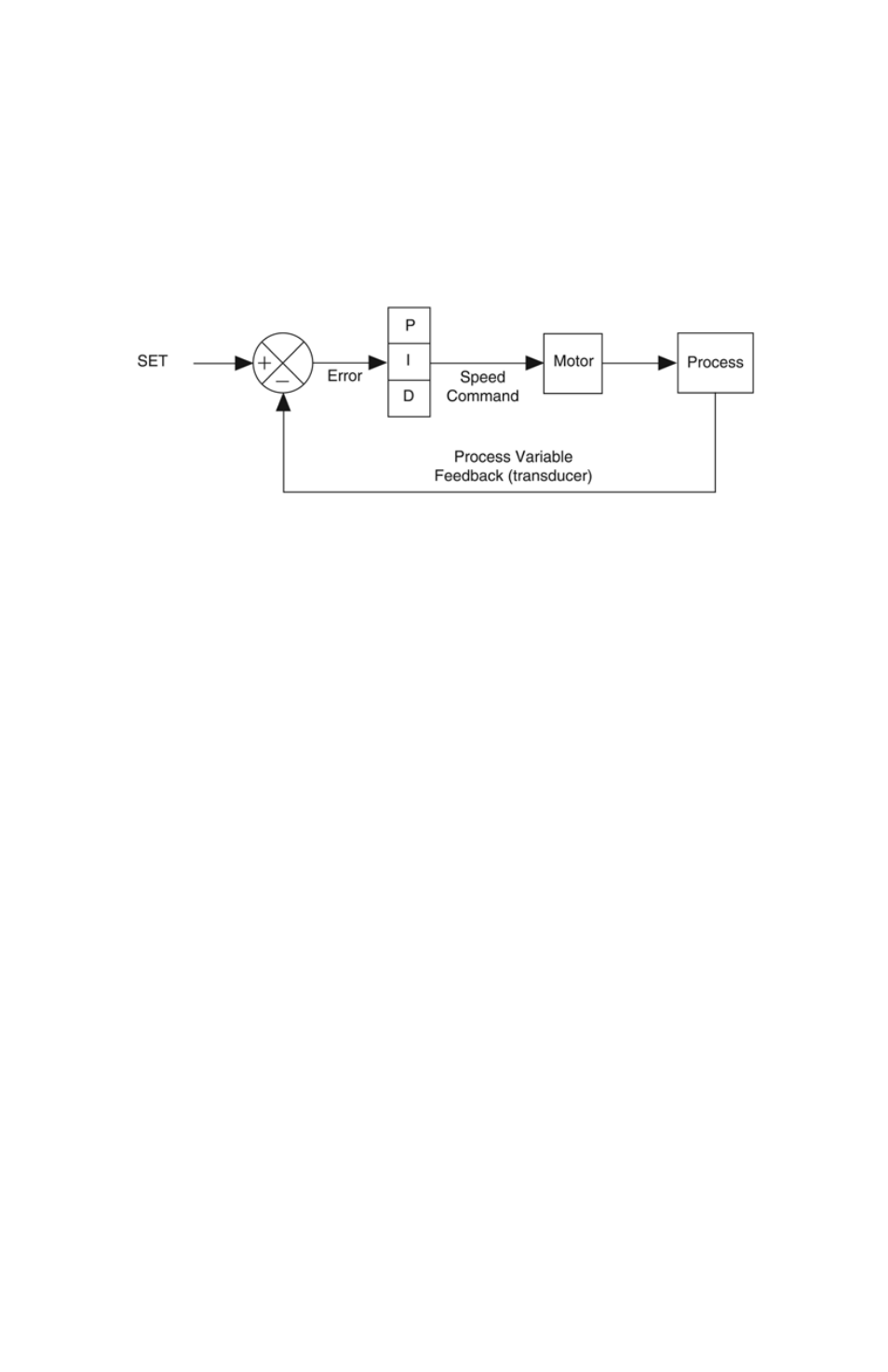

PID Set point Control allows the MICRO Series Control to maintain a process set point, such as PSI

or CFM, without using an external controller. When PID is activated, the MICRO Series Control will

operate in a closed-loop fashion, automatically adjusting the motor speed to maintain the set point.

PID set point control requires feedback from the process in order to compare the process variable “value” to

the set point. The difference between the process variable “value” and the set point is called the error. The

MICRO Series Control will increase or decrease the motor speed in an attempt to minimize the error. By

constantly adjusting the motor speed, the PID control will drive the process toward the set point. Refer to

the PID block diagram below:

19.1

FEEDBACK DEVICES

A transducer or transmitter is required to monitor the process variable and provide feedback to the PID

unit in order to compare the process variable feedback to the set point. A transducer outputs a signal

corresponding to a fixed range of the process variable. A transmitter provides offset and gain adjustments

to allow the output signal to be adjusted to correspond to different ranges of the process variable. Typical

output signals for transducers and transmitters are: 0-5 VDC, 0-10 VDC, or 4-20 mA. The feedback device

must be externally powered, as the drive does not have a power supply for such devices. Program Parameter

74 - PID FB (PID FEEDBACK SOURCE) for the appropriate terminal (TB-5A or TB-5B), and connect

the feedback device as described below:

POT

The positive signal wire (wiper) is connected to TB-5A, and the “high” lead is

connected to TB-6 .

0-5, 0-10 VDC Connect the positive signal wire to TB-5A .

4-20 mA

Connect the positive signal wire to TB-5B .

The common, or negative signal wire, is connected to TB-2 (circuit common).

Feedback devices can be direct or reverse acting. A direct acting device outputs a signal that increases as

the process variable increases . A reverse acting device outputs a signal that decreases as the process variable

increases . The programming of Parameters 75 - FB @ MIN and 76 - FB @ MAX depend on the type of

feedback device being used.

When using a direct acting transducer, Parameter 75 - FB @ MIN should be set to the value of the process

variable feedback corresponding to the minimum feedback signal (0 VDC or 4 mA), and Parameter 76 - FB

@ MAX should be set to the value of the process variable feedback corresponding to the maximum feedback

signal (5 or 10 VDC, or 20 mA).

Example 1:

A 0-100 psi transducer outputs a 4 mA signal at 0 psi and 20 mA at 100 psi . Program Parameter

75 to 0 .0 PSI, and Parameter 76 to 100 .0 PSI (This assumes that Parameter 31 - UNITS is set to pid PSI,

and Parameter 33 - UNITSDP is set to XXX.X).

77