0 installation – LEESON Micro Series Compact Inverters User Manual

Page 24

7.0 INSTALLATION

DRIVES MUST NOT BE INSTALLED WHERE SUBJECTED TO ADVERSE ENVI-

RONMENTAL CONDITIONS! DRIVES MUST NOT BE INSTALLED WHERE

SUBJECTED TO: COMBUSTIBLE, OILY, OR HAZARDOUS VAPORS OR DUST;

EXCESSIVE MOISTURE OR DIRT; STRONG VIBRATION; EXCESSIVE AMBIENT

TEMPERATURES . CONSULT LEESON FOR MORE INFORMATION ON THE

SUITABILITY OF A DRIVE TO A PARTICULAR ENVIRONMENT .

The drive should be mounted on a smooth vertical surface capable of safely supporting the unit without

vibrating . The LCD display has an optimum field of view, this should be considered when determining the

mounting position .

Chassis models must be installed in an electrical enclosure which will provide complete mechanical

protection and maintain uniform internal temperature within the drive’s ambient operating temperature

rating. All drive models MUST be mounted in a vertical position for proper heatsink cooling.

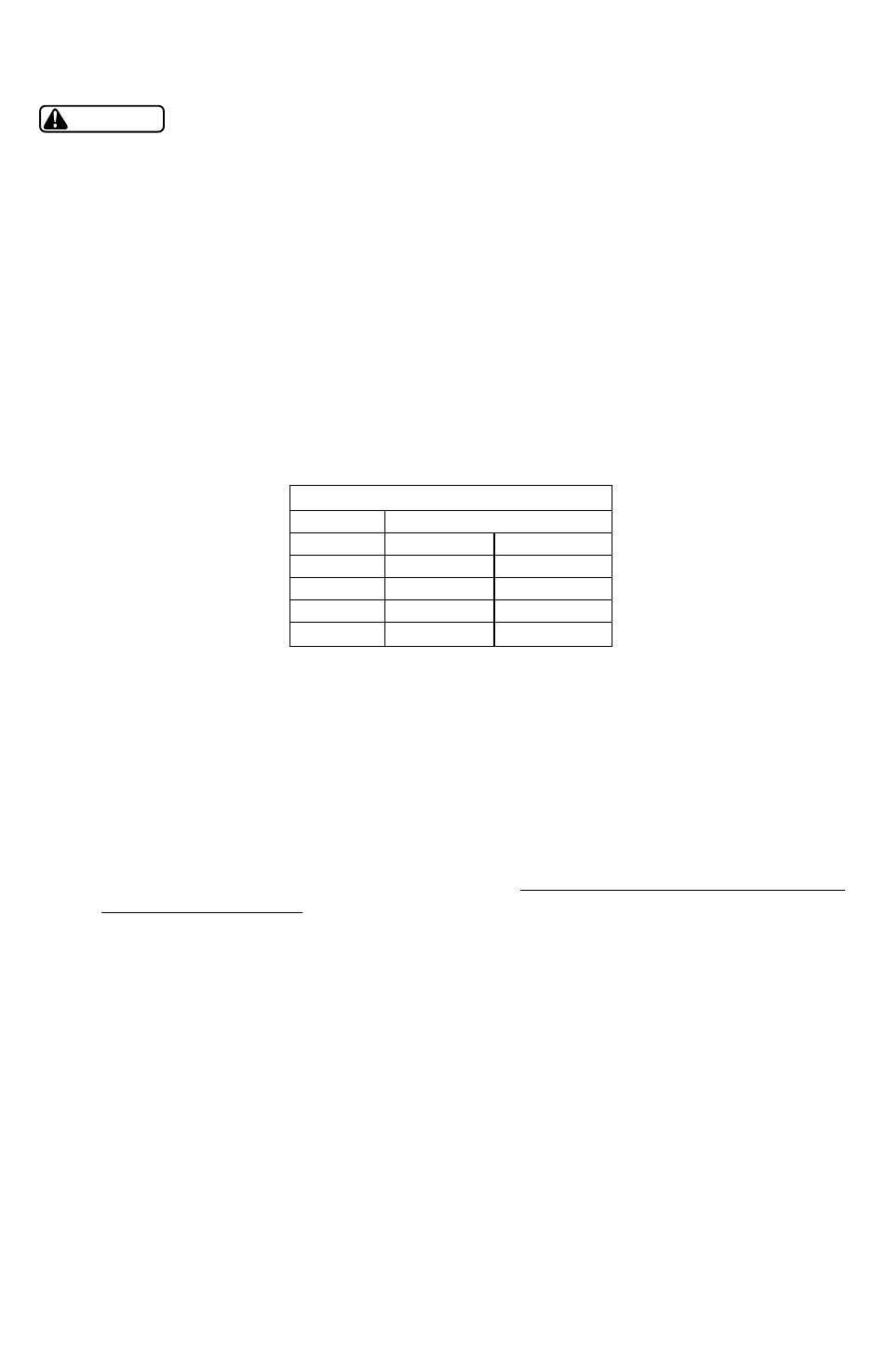

Maintain a minimum spacing around the drive as follows:

If it is necessary to drill or cut the drive enclosure or panel, extreme care must be taken to avoid damaging

drive components or contaminating the drive with metal fragments (which cause shorting of electrical

circuits). Cover drive components with a clean cloth to keep out metal chips and other debris. Use a

vacuum cleaner to clean drive components after drilling, even if chips do not appear to be present . Do not

attempt to use positive air pressure to blow chips out of drive, as this tends to lodge debris under electronic

components . Contaminating the drive with metal chips can cause drive failure and will void the warranty .

All drive models MUST be mounted in a vertical position for proper heatsink cooling. Fans or blowers

should be used to insure proper cooling in tight quarters. Do not mount drives above other drives or

heat producing equipment

that would impede the cooling of the drive . Note the ambient operating

temperature ratings for each drive model .

If it is necessary to drill or cut the drive enclosure or panel, extreme care must be taken to avoid damaging

drive components or contaminating the drive with metal fragments (which cause shorting of electrical

circuits). Cover drive components with a clean cloth to keep out metal chips and other debris. Use a

vacuum cleaner to clean drive components after drilling, even if chips do not appear to be present . Do

not attempt to use positive air pressure to blow chips out of drive, as this tends to lodge debris under

electronic components . Contaminating the drive with metal chips can cause drive failure and will void the

warranty . The MICRO Series is UL approved for solid state motor overload protection . Therefore, a

separate thermal overload relay is not required for single motor applications. In applications where one drive

is operating more than one motor, a separate thermal overload relay is required for each motor per NEC.

22

WARNING

SPACING REQUIREMENTS

SPACING

HP

INCHES

mm

0 .25 - 5

2

50

7 .5 - 25

4

100

30 - 60

6

150

75 - 150

8

200