KB Electronics KBRG-212D User Manual

Page 24

24

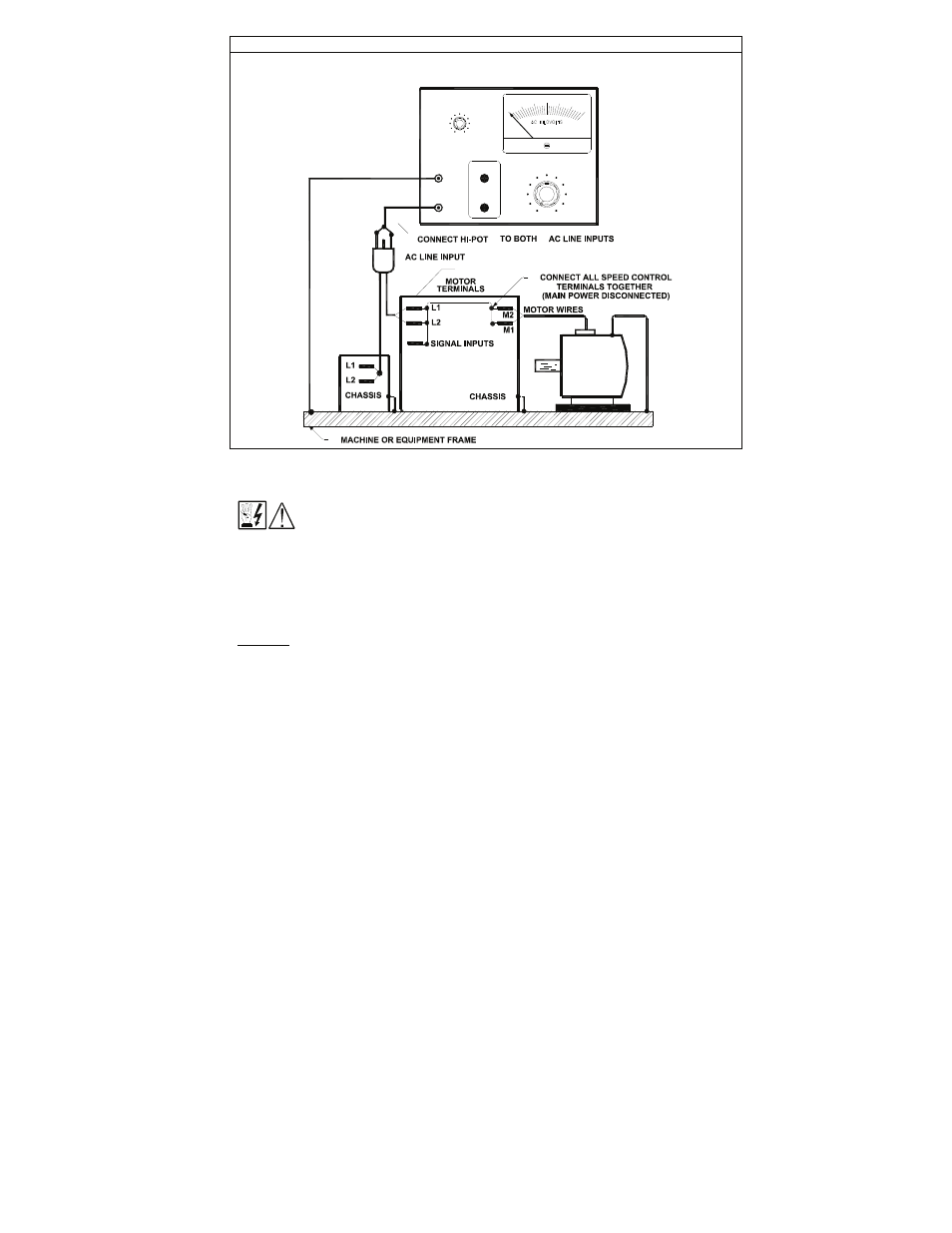

FIGURE 19 - TYPICAL HI-POT TEST SETUP

AUX. EQUPT.

FRAME

MOTOR SPEED CONTROL

HIGH VOLTAGE DIELECTRIC WITHSTAND TESTER

ZERO

(HI-POT TESTER)

RETURN

H. V.

RESET

TEST

LEAKAGE

0mA 10mA

0

VOLTAGE

MAX

1

2

3

9 DRIVE OPERATION

WARNING! READ SAFETY WARNING ON PAGE 5 BEFORE ATTEMPTING TO

OPERATE OR SEVERE INJURY OR DEATH CAN RESULT.

The input voltage can be derived from the wiper of the Main Speed Potentiometer or from an

analog input (voltage following mode). Since the KBRG-212D is a 4-quadrant regenerative

drives, the motor speed will follow both a positive and negative wiper voltage and drive the

motor in both the forward direction and reverse direction. In addition, it will apply both forward

and reverse torque in order to stabilize motor speed.

Example: To understand the concept of a regenerative drive, the operation of an elevator can

be used. If one were to enter the elevator on the first floor and press 10, the motor and control

would have to lift the elevator against gravity. In this mode, the drive would operate like a

conventional speed control which is called "motoring" (the applied load is opposite to the

direction of motor speed).

When the elevator is at floor 10 and floor 1 is pressed, gravity will try to pull the elevator car

down faster than the speed for which it is set. The control will then provide reverse torque to

keep the car form falling faster than the set speed. This operation is regeneration (the applied

load is in the same direction as the direction of motor rotation). Table 10, on page 25

summarizes the different modes of regen operation.