KB Electronics KBRG-212D User Manual

Page 20

20

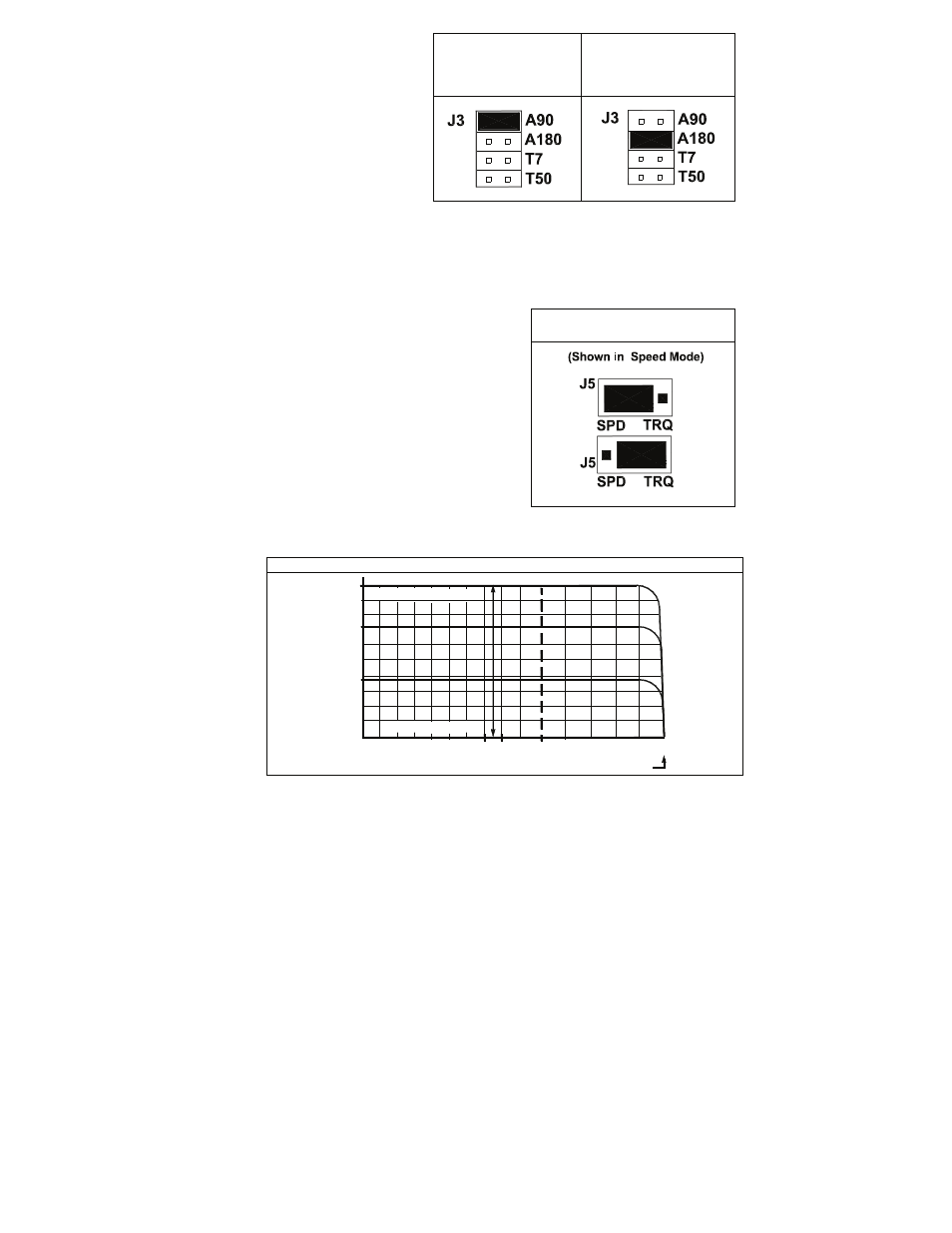

7.2 J3 – Armature Voltage

Output and Tach-Generator

Feedback –

Select the

desired armature voltage by

placing J3 in the proper

position, “A90" or

“A180.”

See Figure 11A.

Note:

For 115 volt AC

line input, J3 must be

set

to

“A90.”

For 230

input, the armature

voltage is normally

set for “A180.” However, it is also possible to set the armature voltage to “A90" for

stepdown operation.

7.2.1 Tach-Generator Feedback (for use with 1800 RPM motors.) –

Jumper J3 is also

used if tach-generator feedback is to be used. If a 7 volt per 1000 RPM tach-

generator is used, set jumper J3 in the “T7" position. For a 50 volt per 1000 RPM

tach-generator, set the jumper in the “T50" position. See Figure 11B.

Note:

When using tach-generator feedback, the

IR Comp Trimpot (See Section 10.4, on

page 27) should be turned to a

minimum setting (full CCW). See

Figure 9, and Section 6.11, on page 19.

7.3

J5 - Speed (SPD) or Torque (TRQ).

Note: Factory setting of J5 is Speed

mode (Default).

In the speed control mode (J5 set to SPD), the

KBRG-212D will provide variable speed

control. The motor speed will be in direct

proportion to the input signal. Both forward and

reverse torque is used to stabilize motor

speed.

See Figures 12, 13 and 14.

FIGURE 11A – J3

ARMATURE VOLTAGE

(90V)

FIGURE 11B – J3

ARMATURE VOLTAGE

(180V)

(Default Position)

FIGURE 12 – J5

SPEED / TORQUE (SPD or TRQ)

Default Position

(Shown in the Torque Mode)

FIGURE 13 – SPEED MODE vs. MOTOR LOAD

CL SETPOINT

APPLIED TORQUE

MO

TOR SPE

ED

(%)

100

90

80

70

60

50

40

30

20

10

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

HIGHER SET SPEED

LOWER SET SPEED