KB Electronics KBAC-29 (1P) User Manual

Page 9

8

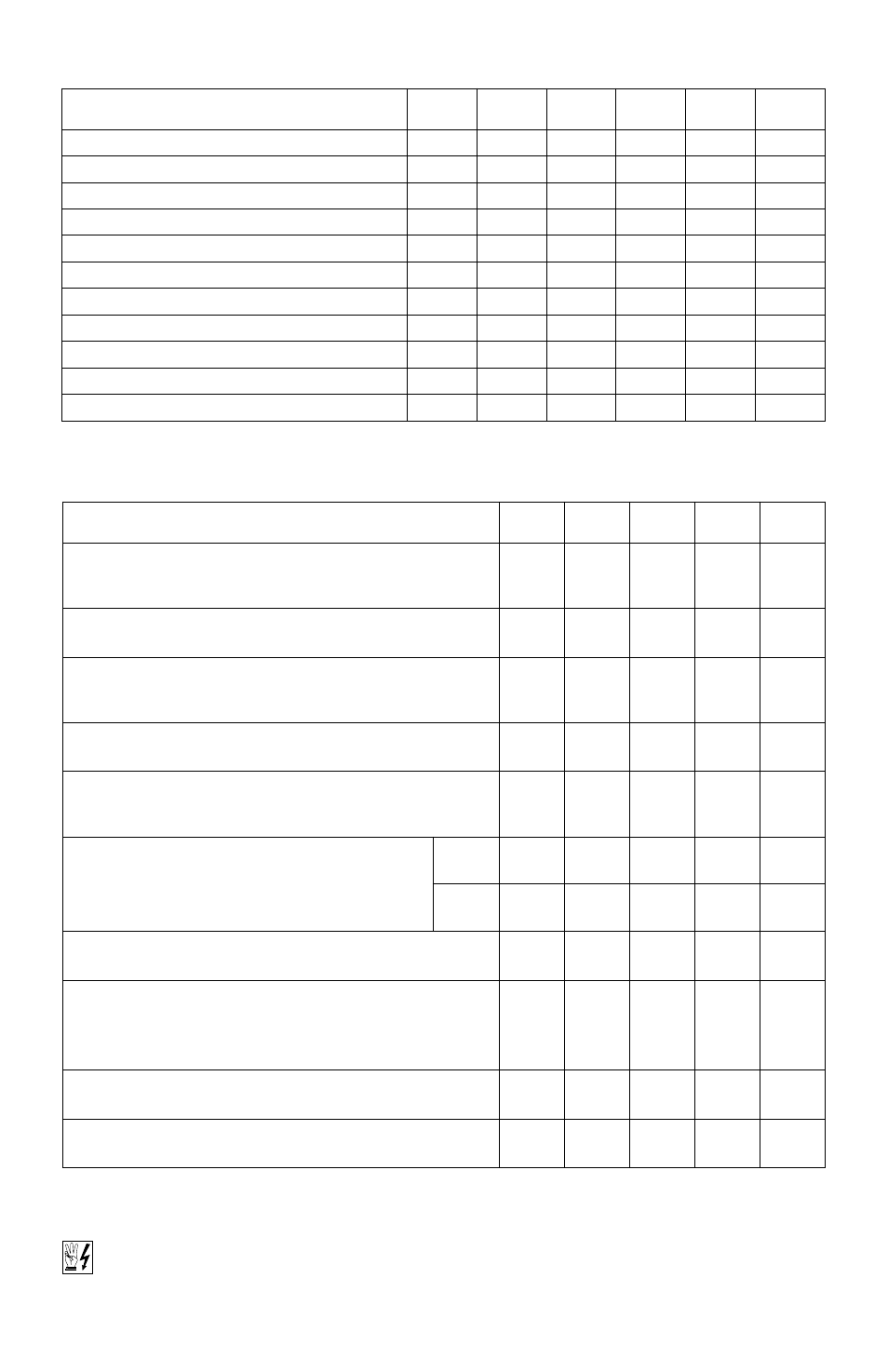

Description

1

PC Board

Designation KBAC-24D

KBAC-27D

KBAC-29

KBAC-45

KBAC-48

AC Line Input Voltage (115, 230)

J1

3

3

—

—

—

Motor Horsepower (see Table 4 - Electrical Ratings, on page 10)

J2

3

3

3

3

3

Automatic Ride-Through or Manual Restart (A*, M)

J3

3

3

3

3

3

Frequency Multiplier (1X, 2X)

J4

3

3

3

3

3

Motor Frequency (50Hz, 60Hz)

J5

3

3

3

3

3

Fixed or Adjustable Boost (FIX, ADJ)

J6

3

3

3

3

3

Regenerative or DC Injection Braking (RG, INJ)

J7

3

3

3

3

3

“Run” or “Fault” Output Relay Operation (R, F)

J8

3

3

3

3

3

Normally Open or Closed Stop Contact (NO, NC)

J9

3

3

3

3

3

Constant or Variable Torque (VT, CT)

J10

3

3

3

3

3

I

2

t Overload Selection (1, 2)

J11

3

3

3

3

3

TABLE 1 – JUMPER SELECTABLE FEATURES

TABLE 2 – OPTIONAL ACCESSORIES

Notes: 1. Bold indicates factory setting. 2. In Automatic Ride-Through Mode, the drive will automatically restart due to a momentary power loss of less

than 2 seconds.

Notes: 1. Complies with CE Council Directive 89/336/EEC Industrial Standard. 2. If a USB communication cable is required, purchase Part No. 19008.

3. Other protocols available – contact our Sales Department.

Description

Model

KBAC-24D

Model

KBAC-27D

Model

KBAC-29

Model

KBAC-45

Model

KBAC-48

Forward-Stop-Reverse Switch – Provides motor reversing and stop functions.

Mounts on the enclosure cover and is supplied with a switch seal to maintain

liquidtight integrity.

9480

9480

9480

9480

9480

On/Off AC Line Switch – Disconnects the AC line. Mounts on the enclosure

cover and is supplied with a switch seal to maintain liquidtight integrity.

9482

9523

9532

9532

9532

Run-Stop-Jog Switch – Selects speed setting from either the Main Speed

Potentiometer or the JOG Trimpot. Mounts on the enclosure cover and is supplied

with a switch seal to maintain liquidtight integrity.

9340

9340

9340

9340

9340

Signal Isolator – Provides isolation between a non-isolated signal source and the

drive. Mounts on the drive’s PC board with four snap-ins.

9600*

9600*

9600*

9600*

9600*

Auto/Manual Switch – When used with the Signal Isolator, it selects remote

process signal or the Main Speed Potentiometer. Mounts on the enclosure cover

and is supplied with a switch seal to maintain liquidtight integrity.

9481

9481

9481

9481

9481

AC Line Filter

1

– Provides Class A RFI (EMI) suppression.

Installs onto the drive’s PC board with quick-connect terminals.

Suffix “S”: Filter is used when On/Off AC Line Switch is installed.

Suffix “NS”: Filter is used when On/Off AC Line Switch is not installed.

Suffix “S”

9516

9512

9479

9479

9479

Suffix “NS”

9507

9512

9515

9515

9515

Multi-Speed Board – Provides multi-speed operation using external contacts or a

PLC. Mounts on the drive’s PC board with four snap-ins.

9489

9489

9489

—

—

Programming Kit

2

– Includes DownLoad Module™ (DLM) handheld programming

device which uploads and downloads drive programs, PC to DLM serial communica-

tion cable, DLM to drive communication cable, and PC Windows® based Drive-

Link™ communication software.

9582

9582

9582

9582

9582

Modbus Communication Module – Allows direct communication between drive

and Modbus

3

protocol.

9517

9517

9517

9517

9517

Liquidtight Fittings – Provide a liquidtight seal for wiring the drive. Kit includes

three 1/2” and one 3/4” liquidtight fittings

9526

9526

9526

9526

9526

* Warning! It is highly recommended that the Signal Isolator (Part No. 9600) be installed when using the

drive with external control signals.