KB Electronics KBAC-29 (1P) User Manual

Page 14

5.1

AC LINE INPUT CONNECTION – Wire

the AC line input to Terminal Block TB1.

GFCI Operation – Do not connect

this drive to an AC power source

controlled by a Ground Fault Circuit

Interrupter. Special software is avail-

able for GFCI operation – contact

our Sales Department.

Note: The rated AC line voltage of the

drive must match the actual AC line

input voltage. On Models KBAC-24D,

27D, the setting of Jumper J1 must

match the AC line input voltage.

Models KBAC-24D, 27D: Designed to

accept single-phase (Terminals “L1”, “L2”) AC line input only. Rated for 208/230 Volt AC line input with

Jumper J1 set to the “230V” position (factory setting). Rated for 115 Volt AC line input with Jumper J1

set to the “115V” position. See Figure 7.

5

WIRING INSTRUCTIONS

WARNING! Read Safety Warning, on page 5, before using the drive. Disconnect main

power before making connections to the drive. To avoid electric shock, be sure to

properly ground the drive. It is highly recommended that the SIAC Signal Isolator (Part No. 9600)

be installed when using signal following.

WARNING! Remote connections of potentiometer, switches, etc., will have wiring that is at line

potential. It is required that the signal isolator be installed for remote connections.

Application Note – To avoid erratic operation, do not bundle the AC line and motor wires with each

other or with wires from signal following, start/stop contacts, or any other signal wires. Also, do not

bundle motor wires from multiple drives in the same conduit. Use shielded cables on all signal wiring

over 12” (30 cm). The shield should be earth grounded on the drive side only. Wire the drive in

accordance with the National Electrical Code requirements and other local codes that may apply.

Be sure to properly fuse each AC line conductor that is not at ground potential. Do not fuse neutral

or grounded conductors. A separate AC line switch or contactor must be wired as a disconnect so

that each ungrounded conductor is opened. For fuse or circuit breaker selection, see Table 5. Also

see Section 10, on page 21.

To maintain the watertight integrity of the drive, be sure to use suitable watertight connectors and

wiring which are appropriate for the application. Model KBAC-24D contains two mounting holes for

standard 1/2” liquidtight fittings (not supplied) (one watertight plug is provided, if only one knockout

is used). Models KBAC-27D, 29, 45, 48 contain two mounting holes for standard 1/2” liquidtight

fittings (not supplied) and one mounting hole for standard 3/4” liquidtight fitting (not supplied) (two

watertight plugs are provided, if only one knockout is used).

The drive is designed with a hinged case so that when the front cover is open, all wiring stays intact.

To open the cover, the four screws must be loosened so they are no longer engaged in the case

bottom. After mounting and wiring, close the cover making sure that the wires do not get caught or

crimped as the cover is closed. Tighten the four screws so that the gasket is slightly compressed.

The recommended tightening torque is 12 in-lbs (14 kg-cm). See Figures 3 and 4, on page 11, for the

tightening sequence. Do not overtighten.

13

Terminal Block

Description

Model

Maximum Wire Size (Cu)

Recommended Tightening Torque

AWG

mm

2

in-lbs

kg-cm

TB1

AC Line Input and Motor Wiring

KBAC-24D

12

3.3

7

8

KBAC-27D, 29, 45, 48

12

3.3

12

14

TB2

Run/Fault Relay Output Contacts

All

16

1.3

3.5

3

TABLE 5 – TERMINAL BLOCK WIRING INFORMATION

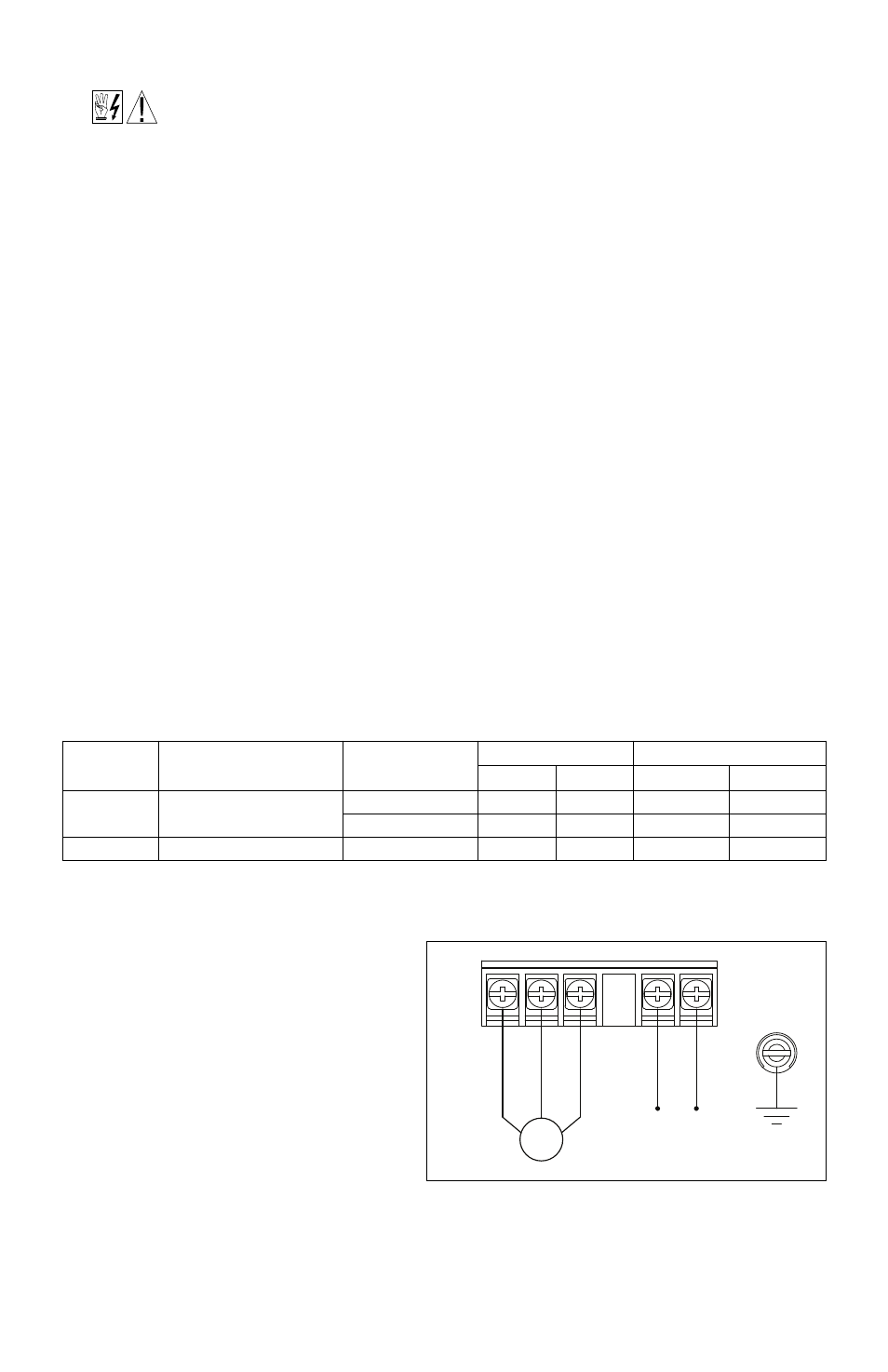

FIGURE 7 – MODELS KBAC- 24D, 27D*

AC LINE INPUT, MOTOR, AND GROUND CONNECTIONS

AC LINE

MOTOR

Motor

V

U

W

AC Line Input

115, 208/230 Volt

Single-Phase

Ground (Earth)

L1

L2

TB1

*Model KBAC-27D is rated 1

1

⁄

2

HP maximum with 115 Volt AC line input and 2

HP maximum with 208/230 Volt AC line input.