KB Electronics KBAC-29 (1P) User Manual

Page 16

inside the drive. The switch assembly may be

removed if a liquidtight seal is used to cover

the hole in the front cover. After applying

power to the drive, momentarily set the

Start/Stop switch to the “START” position.

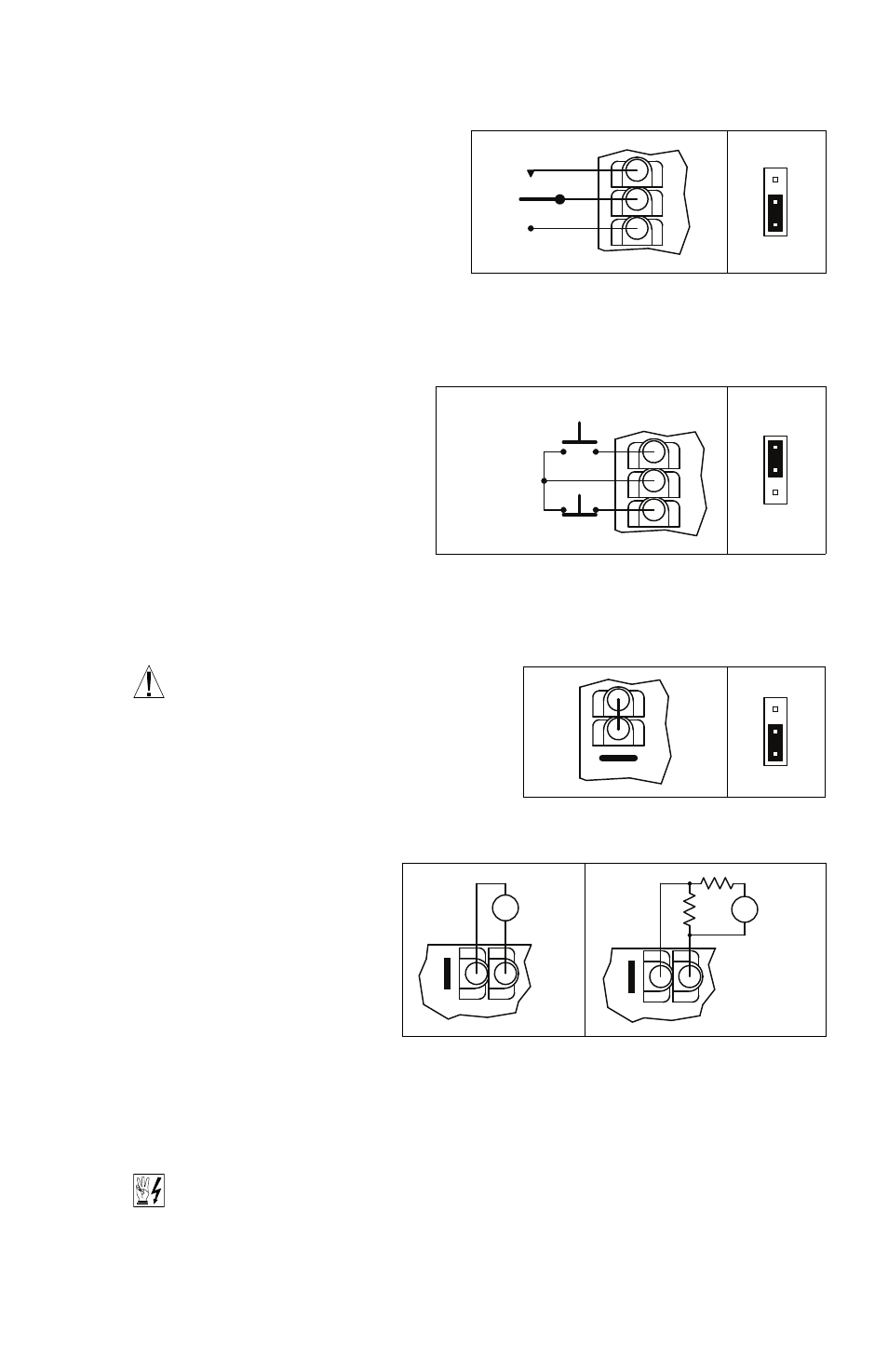

For Start/Stop Switch with normally open stop

contact, set Jumper J9 to the “NO” position

(factory setting). For Start/Stop Switch with

normally closed stop contact, set Jumper J9

to the “NC” position. See Figures 10 and 11.

Also see Section 6.8, on page 18.

5.6

AUTOMATIC RESTART – Automatic

restart requires the elimination of the

Start/Stop Switch. Remove the white,

black, and red wires from Terminals

“RUN”, “COM”, and “STOP”. The wires

may be taped and left inside the drive.

The switch assembly may be removed if

a liquidtight seal is used to cover the hole

in the front cover.

To eliminate the start/stop function, hard-

wire Terminals ”RUN” and “COM” with the jumper

that is provided. Be sure Jumper J9 is set to the

“NO” position. See Figure 12.

WARNING! Using a jumper to eliminate the

start/stop function will cause the motor to

run at the Main Speed Potentiometer setting when

the AC line is applied.

5.7

VOLTAGE FOLLOWING CONNECTION – An isolat-

ed* 0 – 5 Volt DC analog signal input can also be

used to control motor speed in lieu

of the Main Speed Potentiometer.

The drive output will linearly follow

the analog signal input. Wire the sig-

nal input positive lead (+) to Terminal

“P2” and the negative lead (-) to

Terminal “P1”. With external circuitry,

a 0 – 10 Volt DC analog signal can

also be used. See Figure 13.

*If a non-isolated signal is used,

install the SIAC Signal Isolator (Part No. 9600). The SIAC accepts voltage (0 to ±2.5 thru 0 to ±25

Volts DC) or current (4 – 20 mA DC) signal inputs. See Table 2, on page 8.

Note: For signal following operation, the Minimum Speed Trimpot (MIN) must be set fully counter-

clockwise.

WARNING! The signal input must be isolated from the AC line. Earth grounding signal

wiring will damage the drive and void the warranty. It is highly recommended that the

SIAC Signal Isolator (Part No. 9600) be installed when using signal following.

5.8

ENABLE CIRCUIT CONNECTION – The drive can also be started and stopped with an Enable circuit

(close to run, open to stop). See Figure 14, on page 16.

15

FIGURE 10 – REMOTE START/STOP SWITCH CONNECTION

WITH NORMALLY OPEN STOP CONTACT

(J9 Installed in “NO” Position)

COM

Black

STOP

STOP

Red

START

RU

N

White

NO

J9

NC

FIGURE 12 – START/STOP FUNCTION ELIMINATED

(TERMINALS HARDWIRED) (JUMPER INSTALLED)

(J9 INSTALLED IN “NO” POSITION)

COM

STOP

RU

N

NO

J9

NC

FIGURE 11 – REMOTE START/STOP SWITCH CONNECTION

WITH NORMALLY CLOSED STOP CONTACT

(J9 INSTALLED IN “NC” POSITION)

COM

(Push to Stop)

Normally Closed

Momentary Contact

STOP

STOP

Normally Open

Momentary Contact

(Push to Start)

RU

N

START

NO

J9

NC

FIGURE 13 – VOLTAGE FOLLOWING CONNECTIONS (ISOLATED)

0 – 5

Volts DC

P2

P3

P1

V

-

+

0 – 10

Volts DC

P2

P3

P1

10k

V

10k

-

+