Ransburg, Micropak grounding theory, Evolver micropak controller - installation – Ransburg Evolver MicroPak Controller A10406 User Manual

Page 21

MICROPAK GROUNDING

THEORY

Electrical noise refers to stray electrical signals in

the atmosphere at various signal strengths and

frequencies that can affect the operation of elec-

trical equipment. One of the best ways to prevent

this is to shield the equipment and cables with a

continous ground envelope, such that any incident

noise will be conducted to earth ground before it

can affect the circuit conductors.

For conductors inside the Evolver MicroPak

Controller, the grounded enclosure provides this

envelope. For the low voltage cable(s) that run

from the controller to the Evolver spray guns, a

shielded cable has been used. The shield consists

of an overall foiled shield in combination with an

overall braided shield. This provides the most ef-

fective shielding, as the foil covers the “holes” in

the braid, and the braid allows for practical 360°

termination at both ends of the cable.

The AC input cord is not shielded, but instead is

directed to an AC line filter in the 24VDC power

supply as soon as it enters the cabinet. This filter

filters out any noise that comes in on the AC line.

For maximum noise immunity the AC line should

connect to the filter as soon as possible after it

enters the cabinet. Additional noise protection can

be provided by running the AC input line to the

controller in grounded conduit, which is the recom-

mended method and is required by most codes.

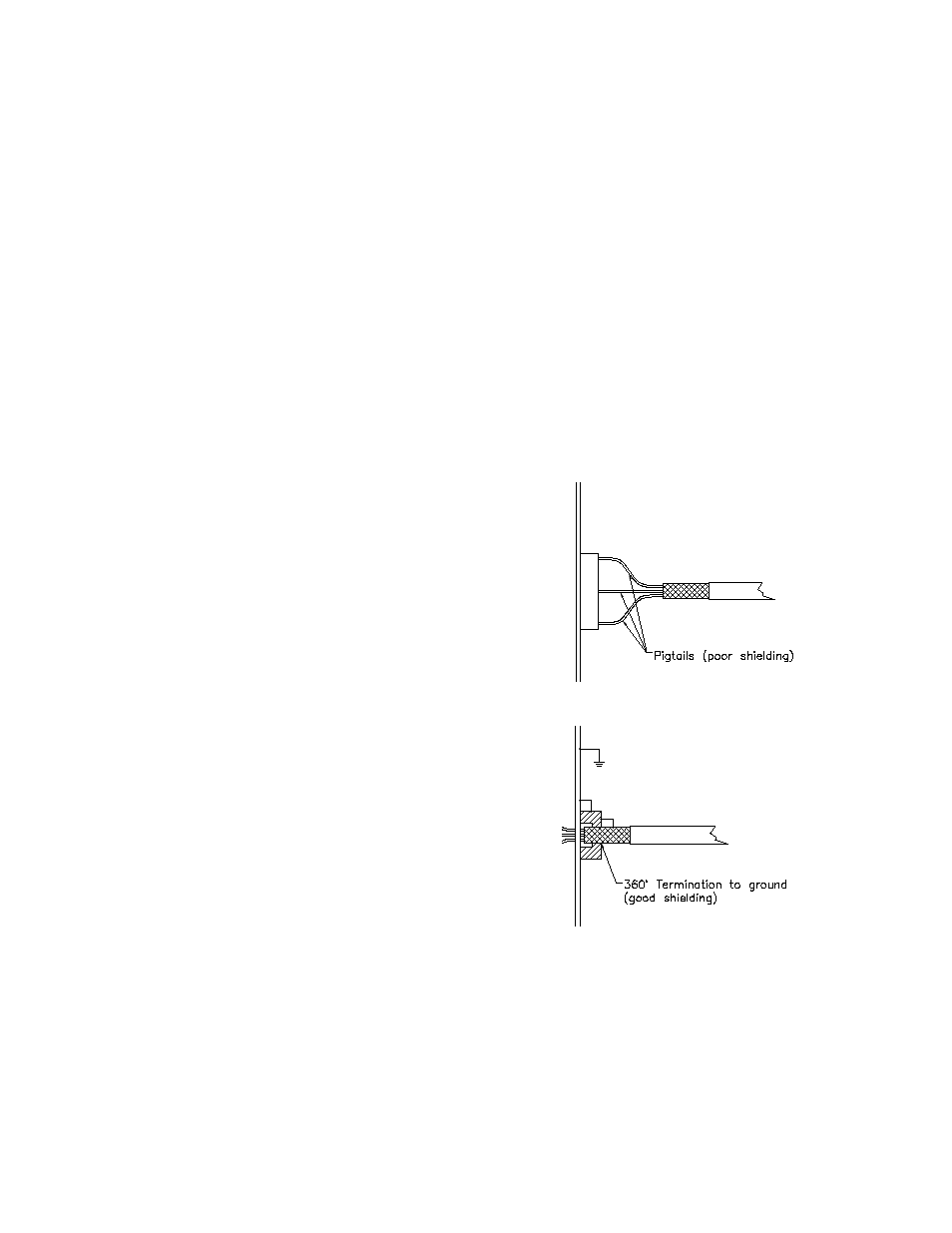

For maximum noise protection any user supplied

input/output (I/O) wiring should be made using

shielded cable or conduit which is connected to

earth ground in a continuous 360° fashion at both

ends. The best way to do this is to use a conductive

connector/fitting at each end of the cable/conduit

that makes contact to the shield/conduit in a full

360° circle around the shield/conduit and makes

contact to the grounded enclosure in the same

fashion. Connecting the drain wire of a shield to

a ground point on or in the cabinet (usually re-

ferred to as pigtailing) is not an effective method

of shielding and can actually make things worse

(see Figure 7).

Figure 7: Cable Connection Examples

A special cable grommet fitting has been provided

for I/O connector P3 of the controller (see Figure

4). When the nut is tightened, the spring in the

grommet compresses and makes 360° contact

with the braid of the cable. This electrically con-

nects the cable braid to ground via the connector

housing and controller back panel.

Using the methods described above, the Evolver

MicroPak controller has been successfully tested

to the stringent standards of the Electromagnetic

Compatibility Directive of the European Union.

The results conclude that the Evolver MicroPak

Controller is neither a source of electrical noise

nor affected by electrical noise when the above

methods are utilized.

Evolver MicroPak Controller - Installation

Ransburg

18

LN-9622-00.5