Ransburg, Description of table 1 interlock and i/o terminals – Ransburg Evolver MicroPak Controller A10406 User Manual

Page 17

DESCRIPTION OF TABLE

1 INTERLOCK AND I/O

TERMINALS

Input Terminals

kV Setpoint (0-10VDC)

0 to 10 VDC remote analog signal input that con-

trols applicator output from 0 to 100 kVDC when

high voltage is enabled. This input is active when

the MicroPak local/remote switch is in the remote

position. Otherwise control is from the kV adjust

knob on the front of the MicroPak. In either mode,

the kV setpoint can be viewed by pushing and

holding the View/Change Setpoint switch (see

Figure 8) on the front of the MicroPak.

Over-Current Setpoint

(0-10VDC)

0 to 10VDC remote analog signal input that sets the

over-current point between 0 and 85 μA when high

voltage is enabled. If the current goes above this

setpoint an over-current fault will occur. This input

is active when the MicroPak local/remote switch

is in the remote position and dipswitch SW3-1 on

the MicroPak process board (see Figure 6A) is set

to the ON position. The range of the over-current

setpoint in this mode is 0 to 3.30VDC equals 0 to

85 microamps. The microamps are limited to 85

for all voltages above 3.30VDC.

If the local/remote switch is in the remote position

and dipswitch SW3-1 is OFF, then potentiometer

R21 on the top of the MicroPak process board (see

Figure 6A) will control the over-current setpoint.

This mode is convenient if it is desired to supply an

analog input signal for the kV setpoint but not for the

over-current setpoint.

Finally, if the local/remote switch is in the local

position, the over-current setpoint is controlled by

the μA adjust knob on the front of the MicroPak.

In any of the modes, the over-current setpoint

can be viewed by pushing and holding the View/

Change Setpoint switch (see Figure 8) on the front

of the MicroPak.

High Voltage Reset (24VDC)

24VDC remote input signal that allows remote

reset of fault conditions. When a fault occurs, a

momentary supply of 24VDC to this terminal will

reset the fault. Faults can also be reset by moving

the kV ON/OFF toggle switch on the front of the

MicroPak to the OFF position and back to the ON

position. This input can also be used to remove

the MicroPak from ready mode.

High Voltage On (24VDC)

Remote input signal that enables high voltage.

When 24VDC is supplied to this terminal, high

voltage will be enabled. This input mode is active

in either local or remote mode when dipswitch

SW3-3 on the MicroPak process board (see Fig-

ure 6A) is set to the ON position and the Ready

input is active (the ready input is made active

by moving the High Voltage Enable Switch (see

Figure 8) to the ON position or by connecting the

remote Ready input (see Table 1) to ground). If

in local mode and dipswitch SW3-3 is set to the

OFF position, high voltage can only be triggered

by moving the kV ON/OFF toggle switch on the

front of the MicroPak to the ON position.

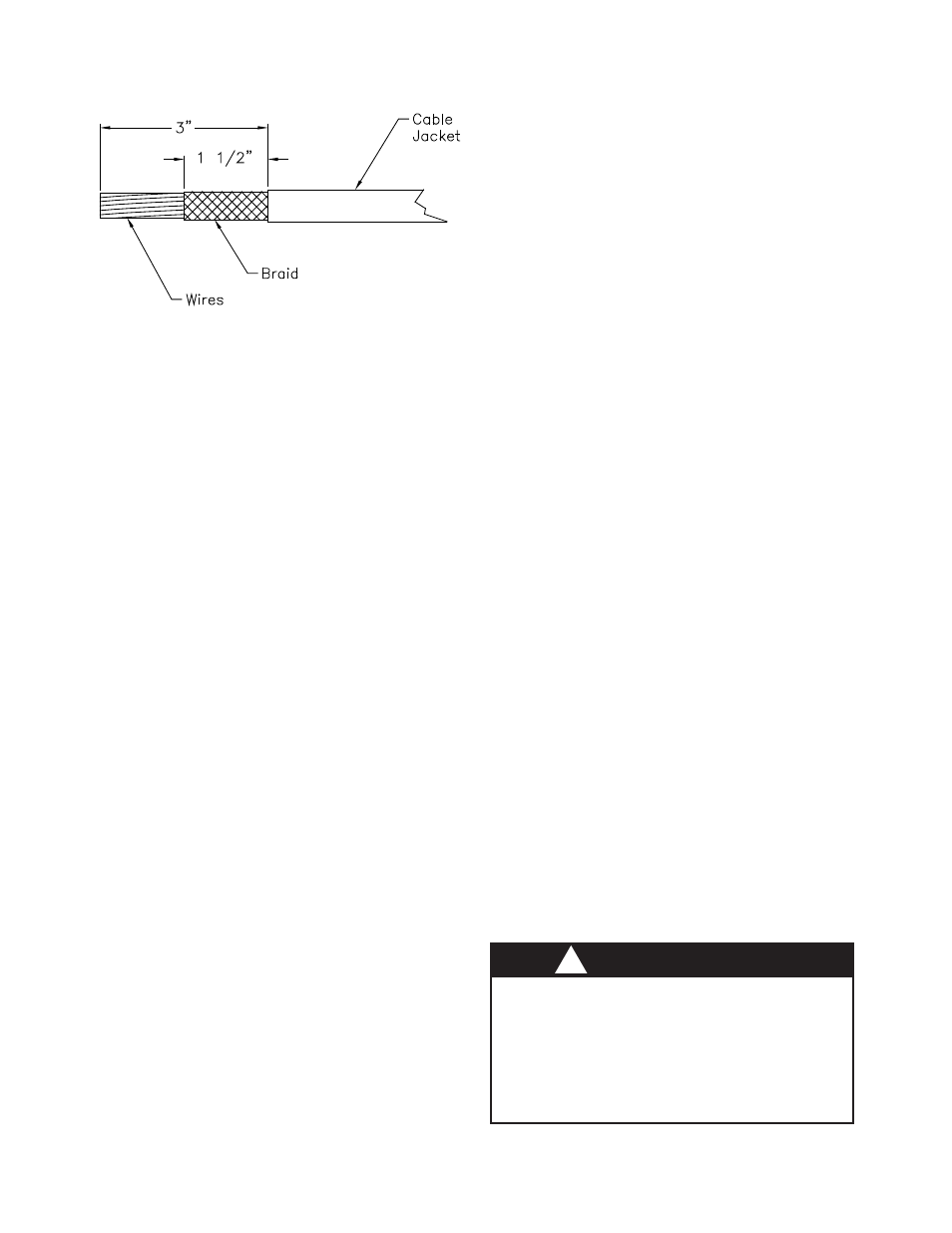

Figure 5: Stripping of I/O Cable(s)

W A R N I N G

!

Never set dipswitch SW3-3 to the OFF

position with the remote Ready input active

(connected to ground) or high voltage will be

on all the time (whenever AC power is on).

Ensure dipswitch SW3- 3 is ON whenever

the Remote Ready input is active.

Evolver MicroPak Controller - Installation

Ransburg

14

LN-9622-00.5