Rma-303 indirect charge - maintenance, Fluid tube removal/replacement – Ransburg RMA Indirect A12869 User Manual

Page 70

RMA-303 Indirect Charge - Maintenance

65

LN-9268-11.4

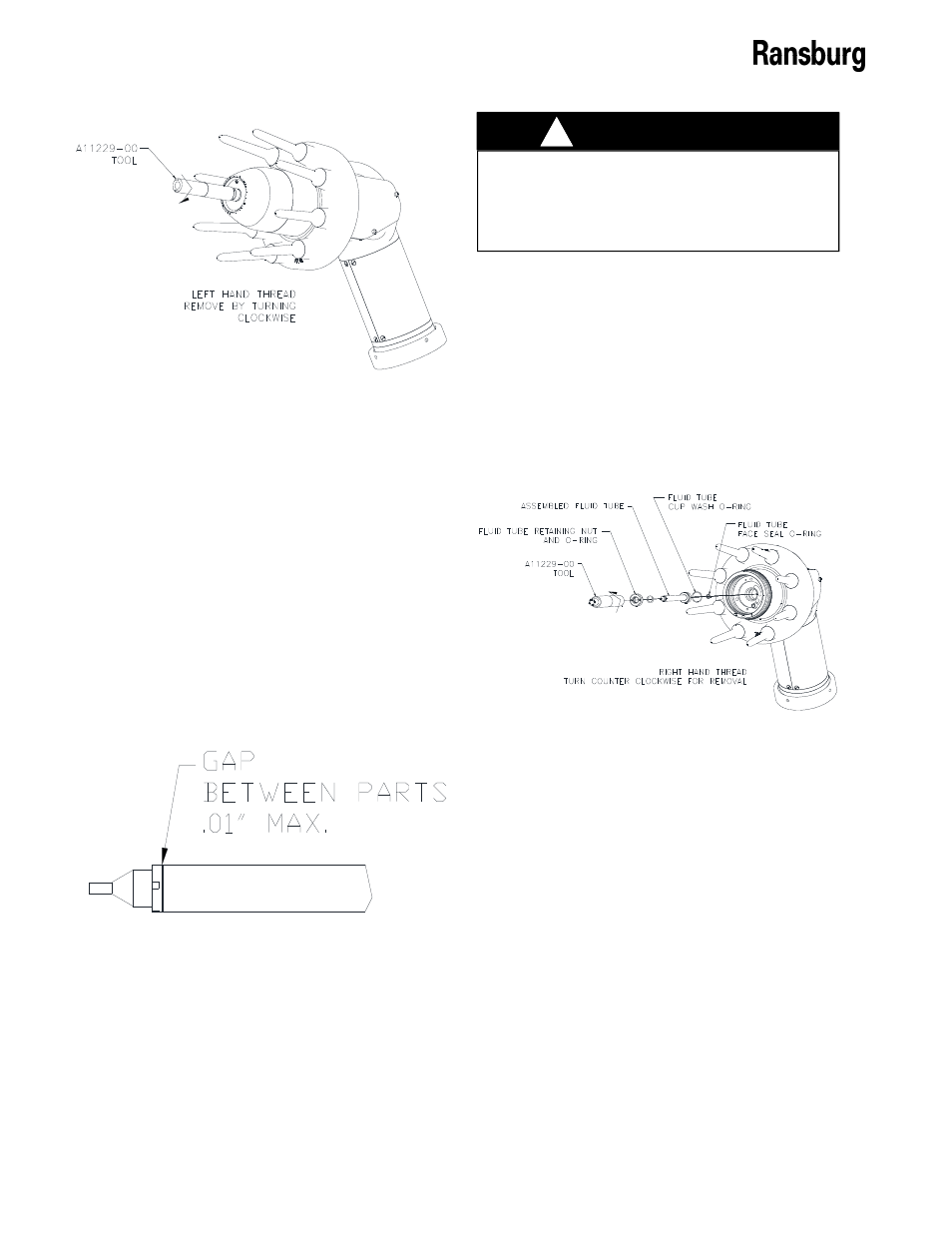

Figure 30: Reinstall Fluid Tip

Figure 31: Fluid Tip/Tube Gap

!

W A R N I N G

Figure 32: Fluid Tip Removal

Replacement

Ensure the tip openings are fully open and

clean. Apply an O-ring lubricant to the O-ring

to help hold it in place on the fluid tip. Insert

the O-ring into the undercut groove on the tip.

Place the tip on the tool and tighten in a coun-

ter-clockwise

direction into the fluid tube. Do

not over-tighten.

There will be a small gap

between the flange of the fluid tip and the fluid

tube (see Figure 31). Insure the O-ring is

properly positioned when complete. Tighten to

25-30 lbs.- in. (2.83-3.4 Nm) torque.

> When removing fluid tip while turbine is still

installed, make sure to clean paint or fluid that

may have leaked or run onto the shaft or

threads.

Fluid Tube Removal/Replacement

Removal

Using the fluid tip/tube removal tool (A11229-

00), place the pinned end of the tool towards

the fluid tube retaining nut and engage the

pins into the holes. Turn the tool counter-

clockwise to remove (see Figure 32).

Replacement

Lubricate all O-rings with a suitable O-ring lub-

ricant. Push the fluid tube into the pocket of

the atomizer body. Seat the tube by pushing

while rocking the tube from side to side. In-

stall the fluid tube retaining nut over the tube.

Tighten the retaining nut firmly tight using the

removal tool in a clockwise direction. Tighten

to 65-75 lbs.- in. (7.34-8.47 Nm) torque.